Product Description

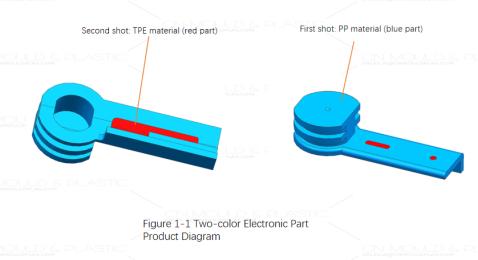

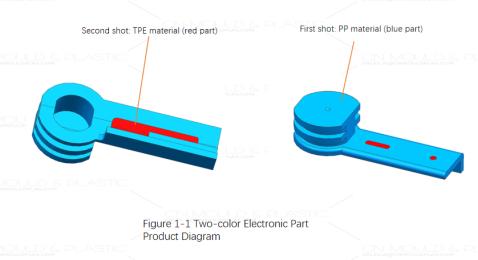

Figure 1-1 shows a two-shot product diagram of an internal part for a packaging application. The average wall thickness is 1.25 mm, with overall dimensions of 13.1 mm × 26.8 mm × 58.1 mm. The green section represents the first material, PP, with a weight of 2.9 g, while the orange section is the second material, TPE (a soft elastomer), weighing 0.33 g. The mold is designed for 4+4 cavities per cycle and demands high aesthetic standards, classifying it as a precision two-shot mold.

Design Highlights

Parting Line and Ejection Direction

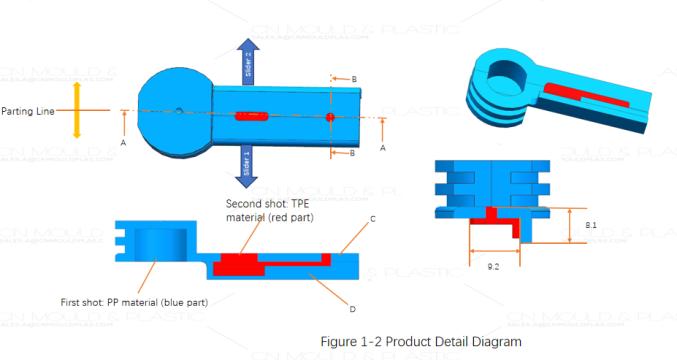

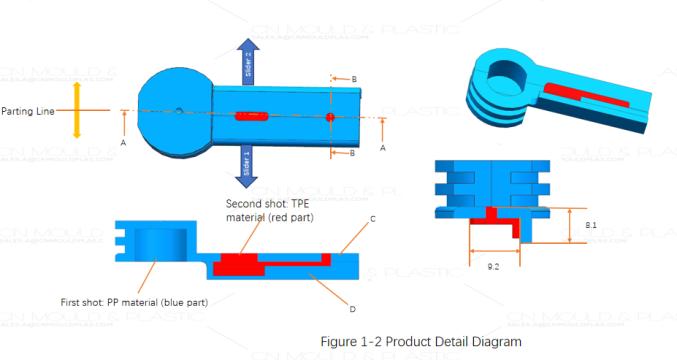

The product structure is not complex, resulting in a simple parting line. Both sides of the part feature undercuts, which can be formed using a half slider (split slider) mold structure, as shown in Figure 1-2. Determining whether to locate these sliders on the fixed or moving half requires further analysis of the product.

Referring to Section A-A in Figure 1-2, the second-shot TPE material is entirely located on side D. According to the basic principle of simple two-shot mold design – different part shapes on the fixed half, identical shapes on the moving half – the initial consideration was to design side D of the two-shot part on the fixed mold cavity side and side C on the moving mold side. However, analysis of the available space on side D (see Section B-B in Figure 1-2) revealed that the width and depth of this area are only 8.1 mm and 9.2 mm, respectively. This space is insufficient to accommodate a hot nozzle. Adding a cold runner segment as an auxiliary gate would necessitate secondary processing to remove the cold runner after injection, increasing production costs and reducing efficiency. Consequently, side D is unsuitable for the fixed mold cavity side, meaning this two-shot mold cannot follow the basic principle of simple two-shot mold design.

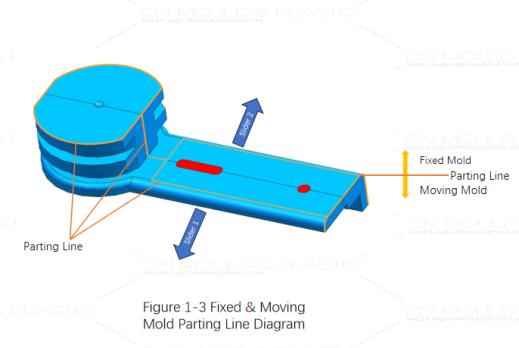

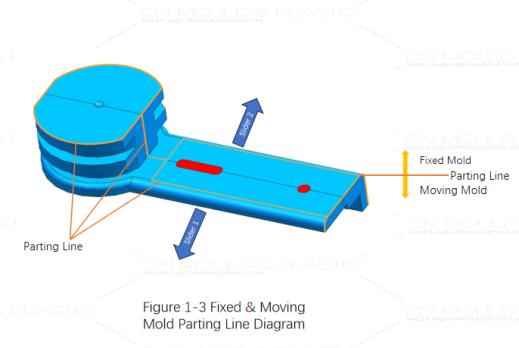

In summary, it was decided to design side C of the part on the fixed mold cavity side and side D on the moving mold core side. However, this introduces a new design challenge: As seen in Section A-A of Figure 1-2, the second-shot TPE is entirely on side D. This means the second shot is formed on the moving mold core side, contrary to the conventional two-shot mold design where the second shot is typically in the fixed mold cavity. Considering that the two-shot injection molding machine for this mold lacks a rotary table on the moving platen, a rotating moving core approach was adopted. This solution enables two-shot molding by rotating the moving core to alternate between two different core positions. Undercuts on both sides of the part are handled by Harvard sliders, with the parting line running through the middle of the part, as shown in Figure 1-3.

Gate Design

The two-shot mold is configured for an L-type two-shot injection molding machine. This machine has no rotary table on the moving platen; its secondary nozzle is perpendicular to the primary nozzle and is located opposite the operator.

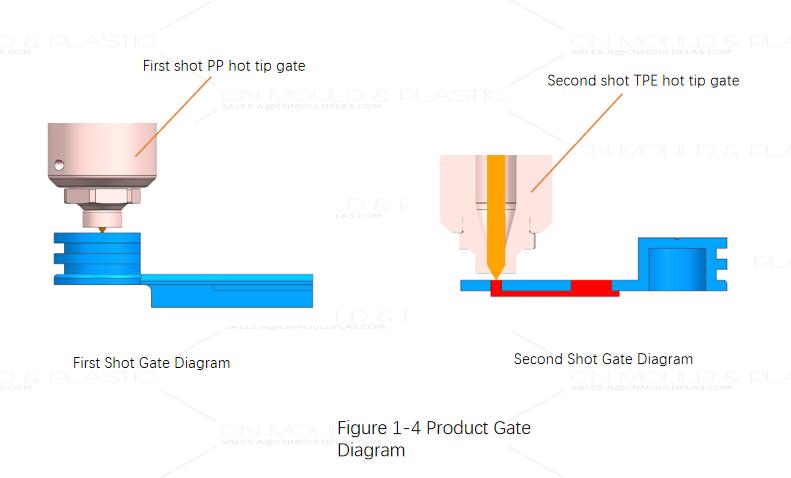

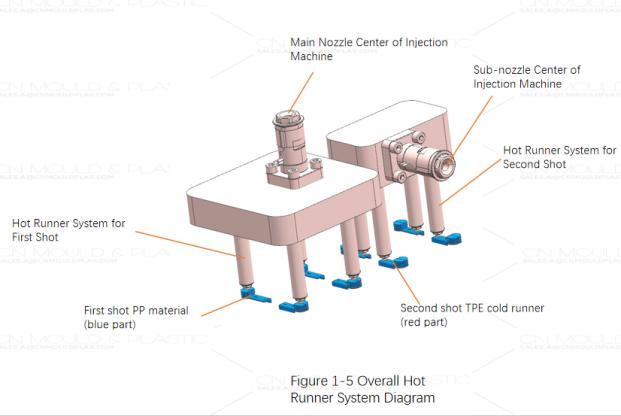

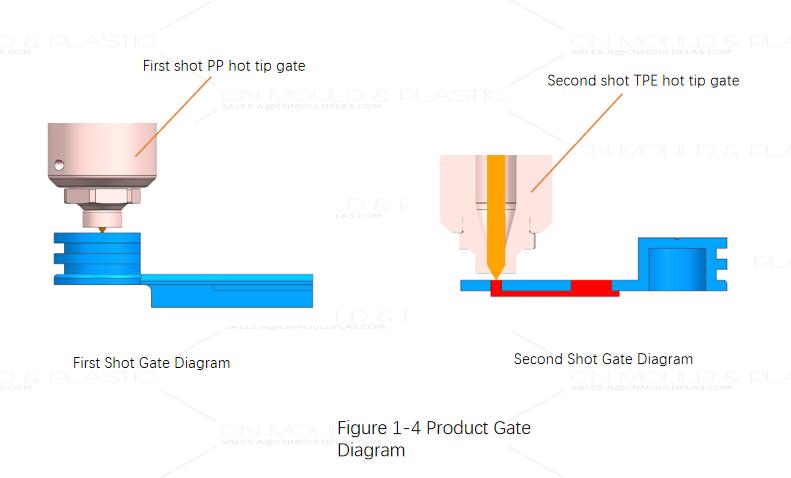

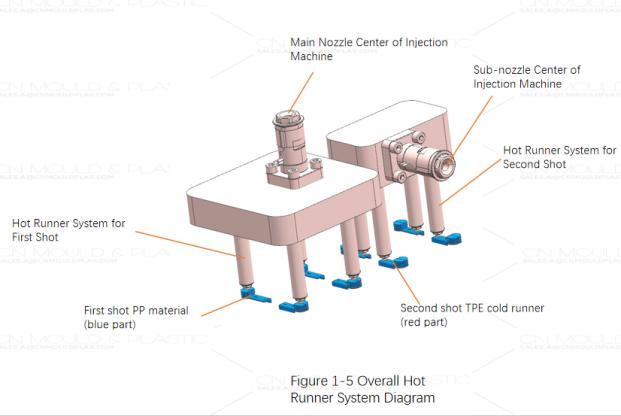

Given the product's small size and the material combination of PP for the first shot and TPE for the second, a single pin-point hot nozzle is suitable for gating. Figure 1-4 shows the gate design for the two-shot product, and Figure 1-5 illustrates the overall hot runner system.

Product Ejection

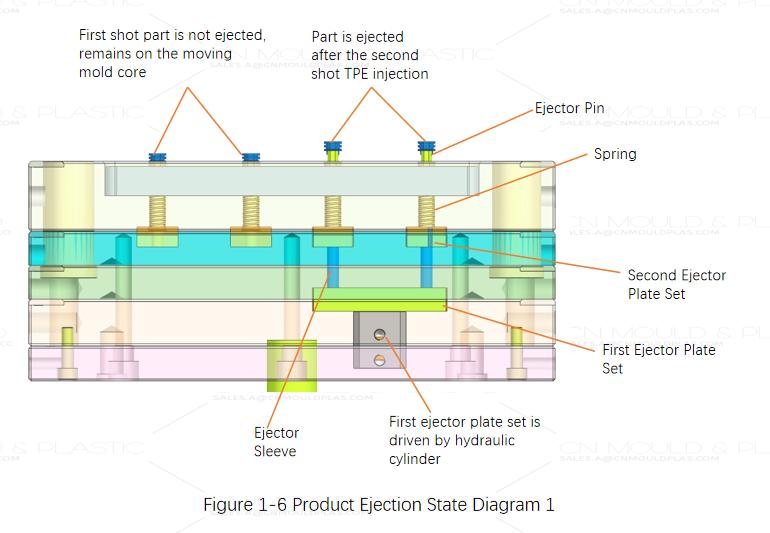

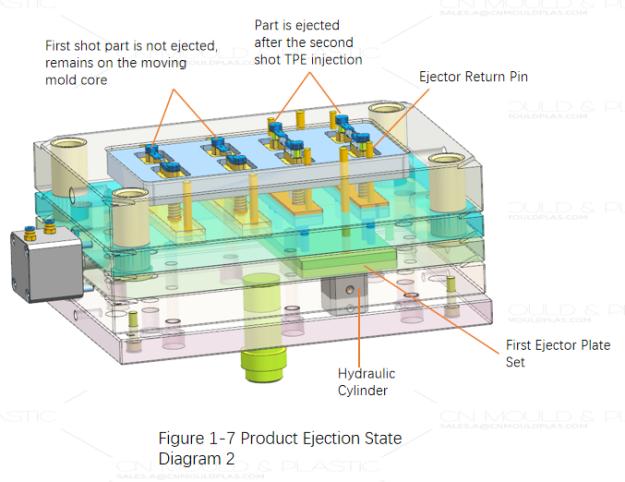

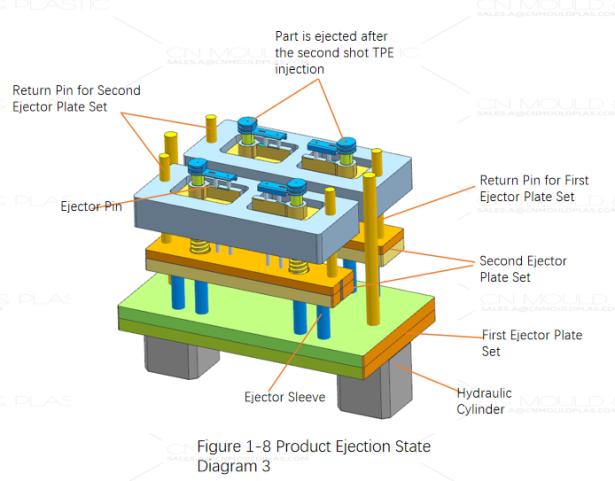

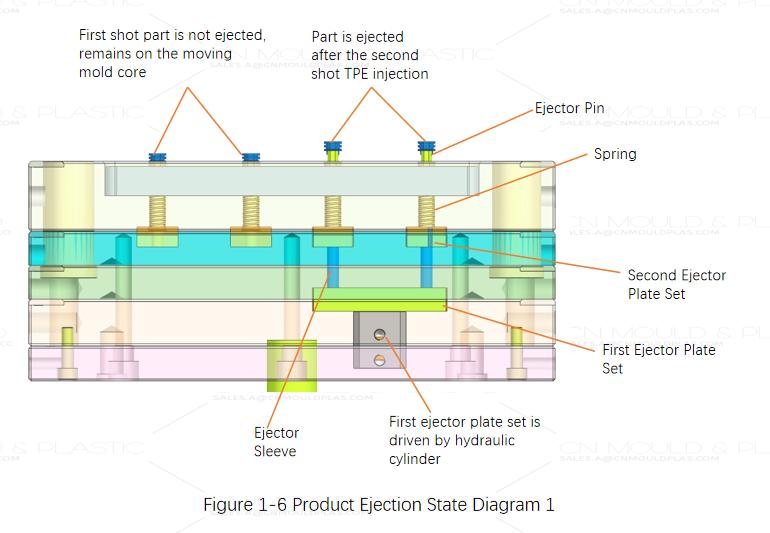

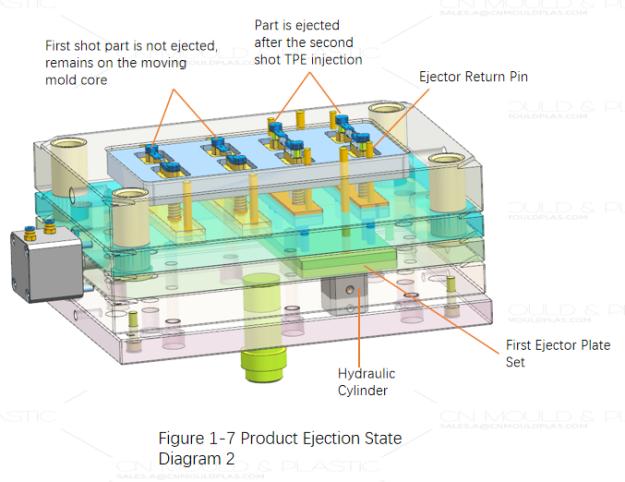

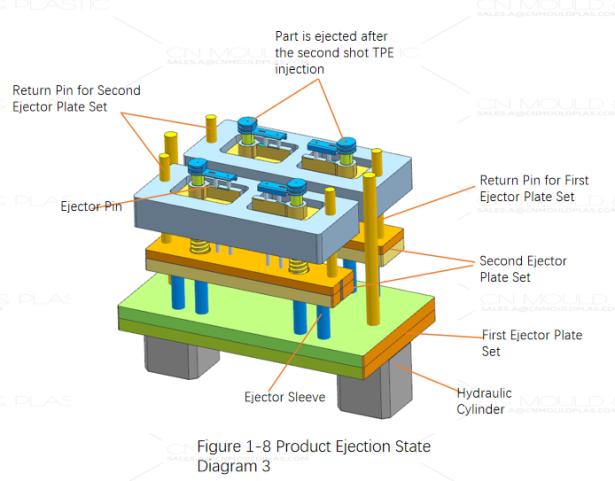

In this mold structure, the ejector plate and ejector retainer plate on the moving half rotate along with the core. Ejection occurs at the second-shot position. This mold is no exception, employing standard ejector pins and blade ejectors for ejection at the second station. However, the ejection mechanism requires a staged ejection process, where the two sets of ejector plates operate in sequence. Figures 1-6 to 1-8 show the ejection sequence. After the second-shot TPE is injected and molded, the mold opens. A hydraulic cylinder connected to the first ejector plate set drives this set, which in turn pushes the second ejector plate set via push rods. This final action drives the ejector pins and blade ejectors mounted on the second set to eject the finished part. Throughout this process, the first-shot part remains on the moving mold core and is not ejected.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk