We are excited to announce that CN Mould & Plastic will showcase our advanced manufacturing capabilities at K 2025 – the world’s leading trade fair for plastics and rubber in Düsseldorf, Germany.

Visit Us At:

Hall 8B, Booth H75

Date: October 8–15, 2025

1.Precision Silicone Molding Solutions

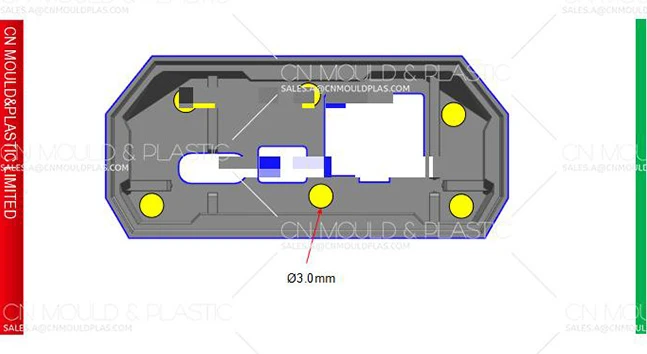

Silicone compression molding for medical, automotive, and consumer electronics

Liquid Silicone Rubber (LSR) injection molding for complex components

2.Custom Rubber & Plastic Parts

High-performance seals, gaskets, dampers, and insulation products

End-to-end support from design to mass production

3.Innovative Automation & Quality Control

Integrated robotics for efficient part handling and assembly

Strict quality standards ensuring consistency and reliability

Expertise: Over 20 years of experience in custom rubber and plastic molding

Quality: ISO-certified processes with full traceability

Global Support: Simplified supply chain with on-time delivery

Whether you’re developing a new product or optimizing an existing design, our team is ready to help you achieve your goals with innovative materials and precision engineering.

Schedule a meeting with us at K 2025 by replying to this email or stopping by Booth H75 in Hall 8B. We look forward to discussing how we can support your next project!