The dust has settled on K 2025 in Düsseldorf, and the message from the heart of the plastics industry is clearer than ever: the future is integrated. At CN MOLD & PLASTIC's booth in Hall 8B, we didn't just showcase components; we demonstrated a seamless production flow where injection molding and automated assembly converge into a single, intelligent process. This is Industry 4.0 in action.

The Paradigm Shift: From Isolated Steps to a Unified Cell

For decades, the standard process has been linear:

Mold a part → Remove it → Transport it → Assemble it elsewhere.

This approach introduces handling, waiting, and potential damage. At K 2025, we showcased a new reality powered by 6-axis robots:

Mold a part → Reorient it inside the cell → Place an insert/another component → Assemble → Eject a finished sub-assembly.

This closed-loop system is the core of the smart, connected factory.

How It Works: The Anatomy of an Integrated Cell

Our live demonstrations highlighted three key stages of this integrated approach:

1.Intelligent Part Removal & Presentation

The 6-axis robot doesn't just eject the part. It grips the component with a custom EOAT (End-of-Arm-Tooling) and actively reorients it for the next step, presenting it precisely to a vision system or an assembly station.

2.In-Mold or Post-Mold Assembly

This is where the magic happens. We demonstrated two scenarios:

Insert Loading: The robot places a metal thread, a magnet, or another previously molded plastic part into the mold. The next shot is then injected, overmolding or encapsulating the insert to create a strong, monolithic component.

Post-Mold Assembly: Immediately after ejection, the robot moves the freshly molded part to a dedicated fixture within the cell, where it is pressed, snapped, or ultrasonically welded with another component held by a second gripper.

3.Final Placement and Quality Assurance

The finished sub-assembly is then placed directly onto a conveyor for packaging or the next stage of production, all within a single cycle. Integrated sensors verify successful assembly, creating a fool-proof process.

The Tangible Benefits: Why Integration is No Longer Optional

Visitors to our booth immediately grasped the powerful advantages of this integrated approach:

Drastically Reduced Total Cost: Eliminating secondary handling, dedicated assembly stations, and the associated labor leads to significant savings.

Unmatched Quality & Consistency: Handling the part only once minimizes the risk of scratches, contamination, or damage. Every assembly step is perfectly repeated, cycle after cycle.

Maximum Space Efficiency: Combining multiple processes into a single compact cell optimizes valuable factory floor space.

Data-Driven Production: The entire cell acts as a data node, providing real-time information on cycle time, assembly success rates, and potential bottlenecks for proactive management.

The CN MOLD & PLASTIC Difference: Beyond the Robot

A robot is just one piece of the puzzle. Our expertise lies in engineering the complete system:

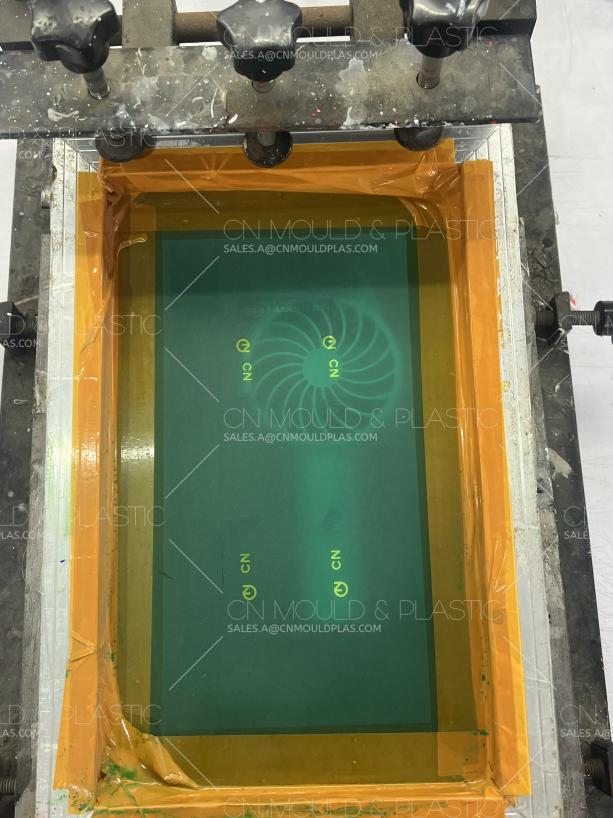

Precision Mold Design: Designing molds that facilitate automated part removal and integrate with assembly sequences.

Custom EOAT Engineering: Developing specialized grippers that can handle multiple components and perform assembly motions.

Seamless System Integration: Ensuring the molding machine, robot, vision system, and peripherals communicate flawlessly.

The conversations at our stand confirmed that the industry is ready for this evolution. The question is no longer "Should we automate?" but "How intelligently can we integrate?"

Thank you to everyone who visited us at K 2025. The energy and insightful discussions have inspired us to push the boundaries of what's possible in integrated molding even further.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk