Product Description

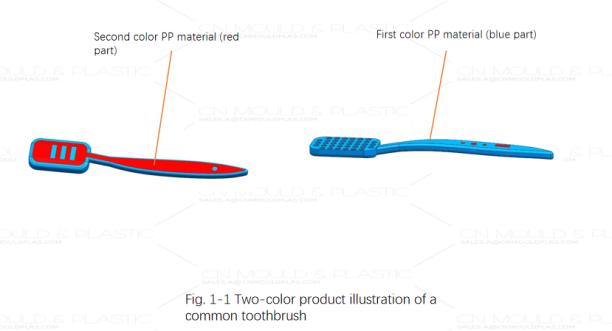

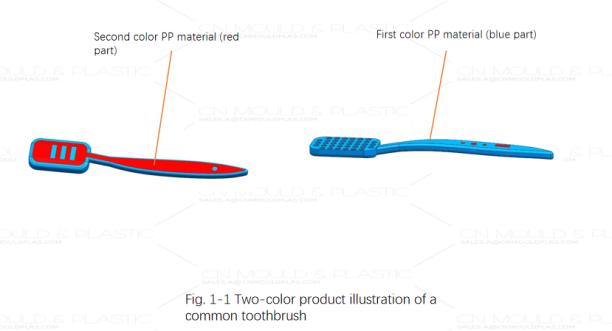

Figure 1-1 shows a two-color product diagram of a common dual-color toothbrush. The product has an average wall thickness of 3 mm, with local areas reaching 4 mm. Its overall dimensions are 13.5 mm × 53.2 mm × 17 mm. Both the first and second shots use PP material but in different colors. The green section represents the first shot (PP), weighing 7 g, while the orange section is the second shot (PP), weighing 5 g. The mold is designed for 4+4 cavities per cycle, demands high aesthetic standards with no visible parting lines, and requires an injection cycle time of 24 seconds, classifying it as a precision two-shot mold.

Design Highlights

Parting Line and Ejection Direction

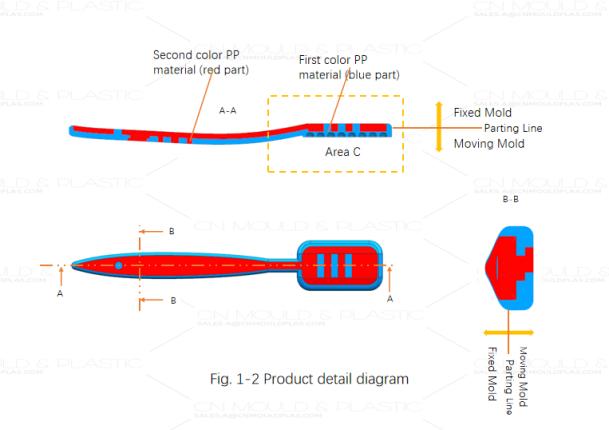

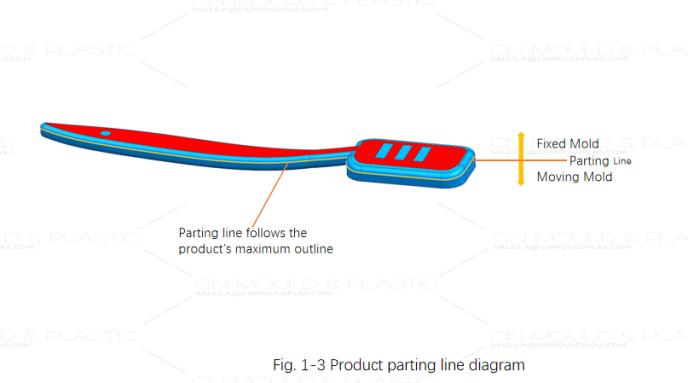

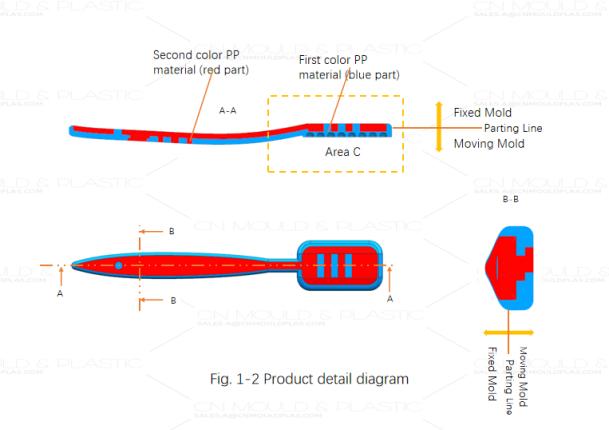

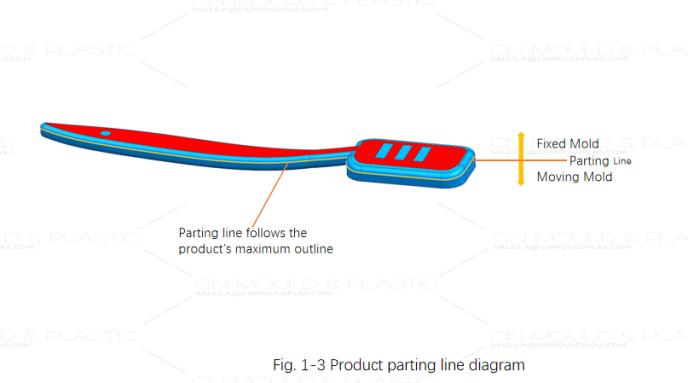

The toothbrush structure is simple and can be directly formed by the fixed and moving halves without sliders, lifters, or other complex mechanisms. The product's maximum contour line can directly serve as the parting line, as shown in Figures 1-2 and 1-3.

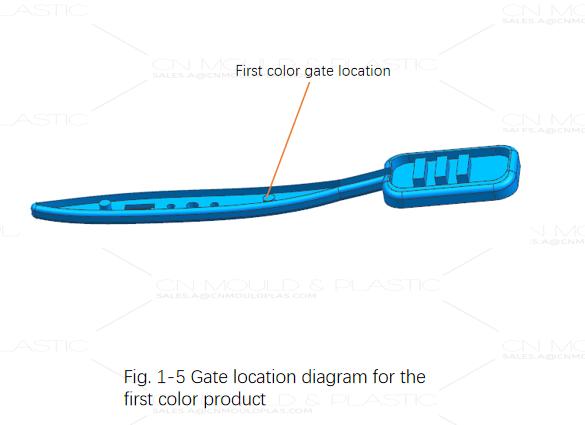

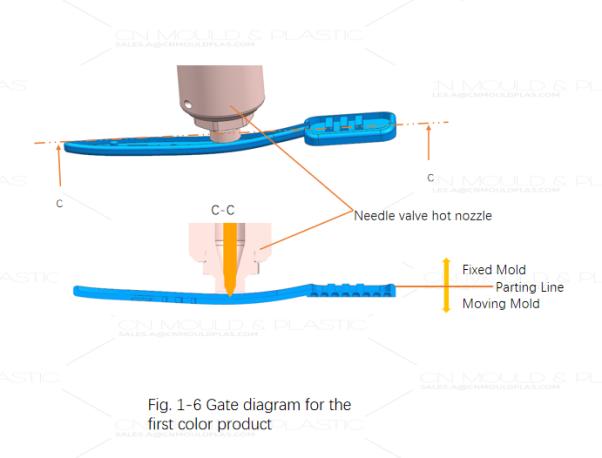

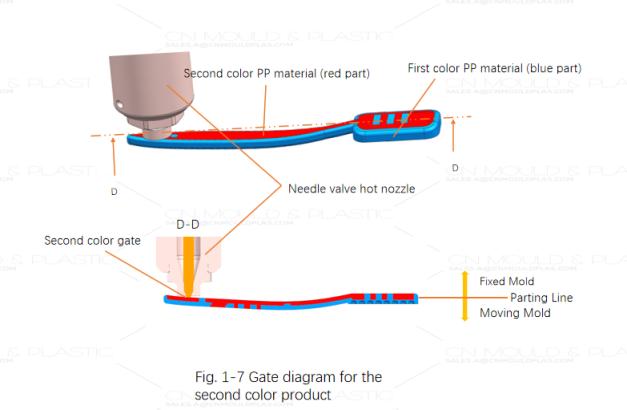

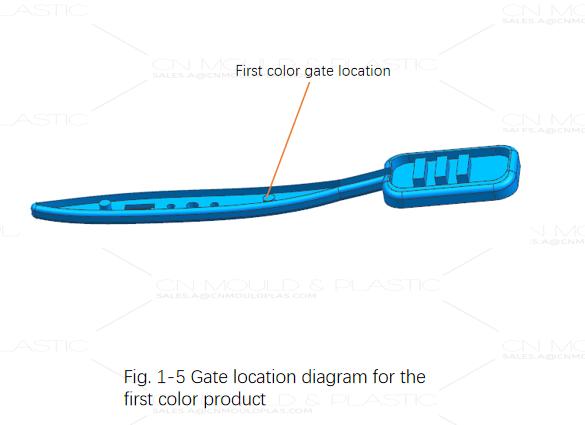

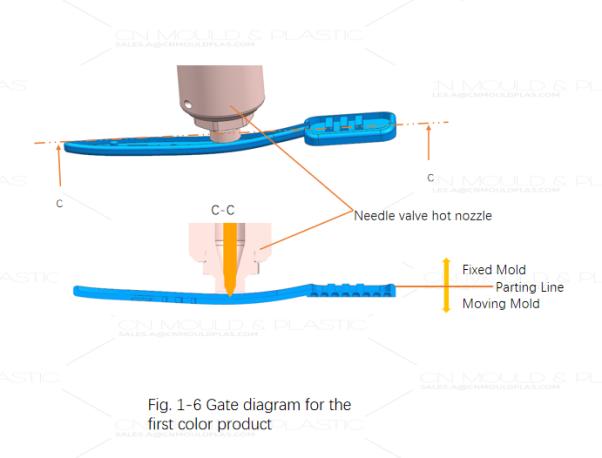

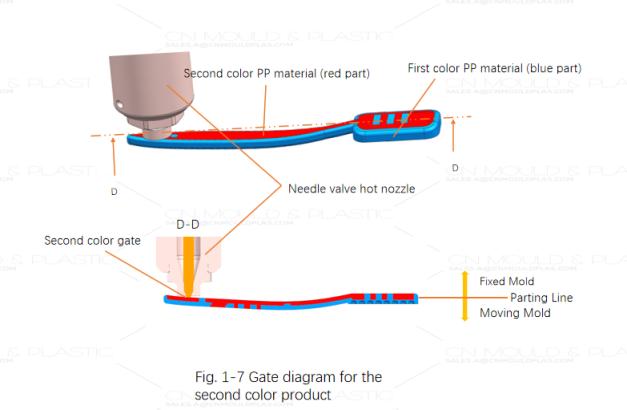

Gate Design

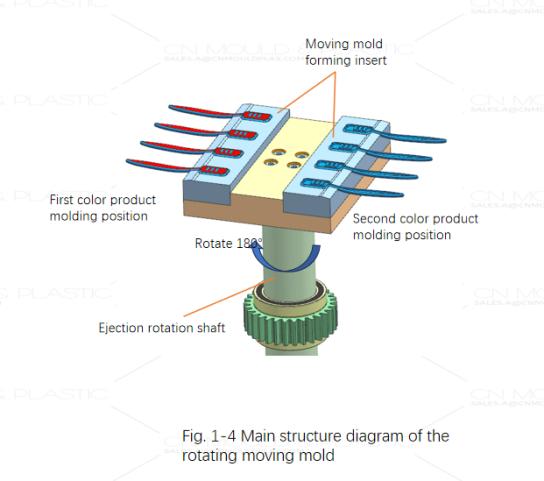

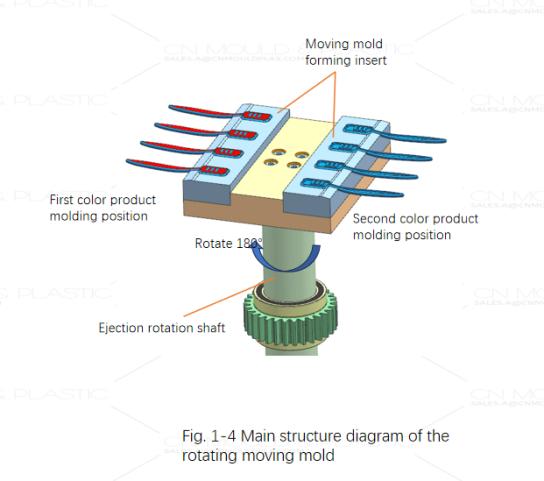

Although the product structure is simple, it does not fully comply with the basic principle of simple two-shot mold design (different part shapes on the fixed half, identical shapes on the moving half). Previous chapters have introduced two-shot mold structures with rotating cores and rotating moving halves. Analyzing this two-color toothbrush product (see Figure 1-2) reveals that, except for area C, both the fixed and moving halves require forming the second-shot material. Therefore, the mold structure can achieve the cavity switch between the first and second shots by rotating the product around area C, enabling two-shot injection molding. Figure 1-4 shows the main structure diagram of the rotating moving half for this mold.

With the main rotating structure determined, the next step is analyzing the gate locations. Considering aesthetics, the gate for the first shot is designed at the product's center, using a valve-gated hot nozzle for direct injection, as shown in Figures 1-5 and 1-6. The second shot will cover the gate vestige of the first shot, ensuring no impact on appearance.

For the second shot, the gate must neither affect appearance nor the product's tactile feel. Therefore, it is positioned on the back end of the product where hands rarely make contact, also using a valve-gated hot nozzle for direct injection. This results in minimal gate marks that are inconspicuous, as shown in Figure 1-7.

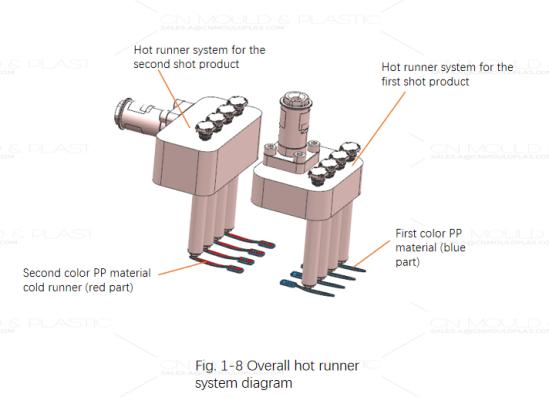

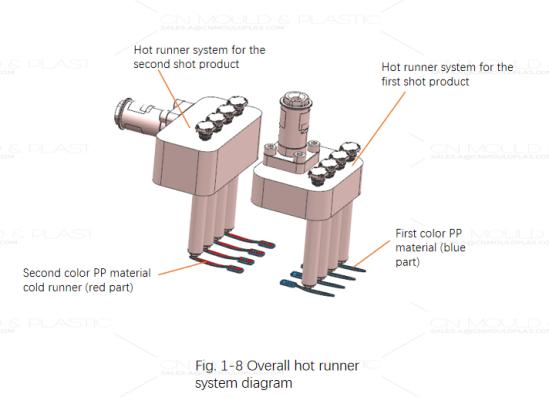

This two-shot mold is configured for an H-type two-shot injection molding machine, where the secondary nozzle is located on the top side (sky side) of the machine. Consequently, the main sprue bushing of the second shot's hot runner system is positioned on the top side. Figure 1-8 illustrates the complete runner system layout for this mold

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk