In the world of injection-molded plastic parts, aesthetics and functionality often go hand-in-hand. Whether for branding, user instructions, safety labels, or purely decorative purposes, adding textures, text, symbols, or marks is a common requirement. However, integrating these features isn't just a graphic design task—it’s a crucial mold design consideration. A poorly placed or poorly designed marking can make ejection difficult, damage the part, or even wear out the mold itself.

This guide outlines the basic design principles for incorporating raised or recessed features on plastic components.

The most important principle is simple: the location and design of any texture or marking must not hinder part ejection.

Features should be oriented parallel to the direction of mold opening to avoid undercuts. If the design requires side actions or lifters just for a logo, it will significantly increase tooling cost and complexity.

Convex vs. Concave: Two Approaches

Features on the plastic part are achieved by machining the opposite geometry into the mold. There are two main design approaches:

On the Part: Text or symbols are convex (stand out from the surface).

In the Mold: The corresponding cavity is engraved or recessed.

Advantage: Easier to machine into the mold steel. The raised plastic is more durable against wear.

Consideration: Raised text on the part can be prone to damage during handling if it's too delicate.

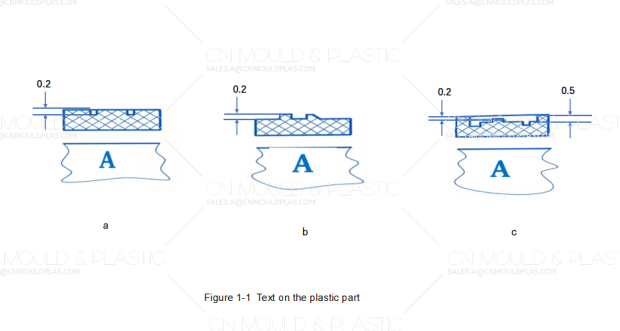

Figure 1-1(a) here: Showing a cross-section of a mold with engraved text creating raised text on the part.)

On the Part: Text or symbols are concave (indented into the surface).

In the Mold: The corresponding text on the mold is raised/protruding.

Advantage: Creates a smooth, flush surface on the part that is protected from abrasion.

Consideration: The raised text on the mold is more vulnerable to damage during cleaning or maintenance. It also requires sufficient draft to ensure release.

Figure 1-1(b) & (c) here: Showing cross-sections of molds with raised text creating indented text on the part.)

For features to be legible, manufacturable, and moldable, follow these general guidelines:

Height/Depth: The height of raised text on the part should be at least 0.2 mm. For indented text, the depth follows a similar rule.

Line Width: The stroke width of letters or symbols should generally be no less than 0.3 mm. A width of 0.8 mm is often recommended for better readability and mold strength.

Spacing: The space between two lines (e.g., in the letter "H") should be at least 0.4 mm to prevent material flow issues during molding and to maintain mold durability.

Borders: If a border surrounds text, it should be at least 0.3 mm higher than the font itself to protect it.

Draft Angle: Always include a draft angle. For text and symbols, a draft angle greater than 10° is recommended to ensure clean and consistent release from the mold without dragging.