Product Description

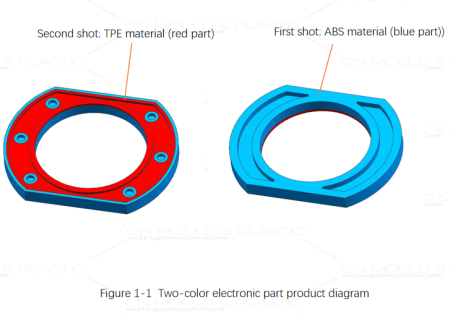

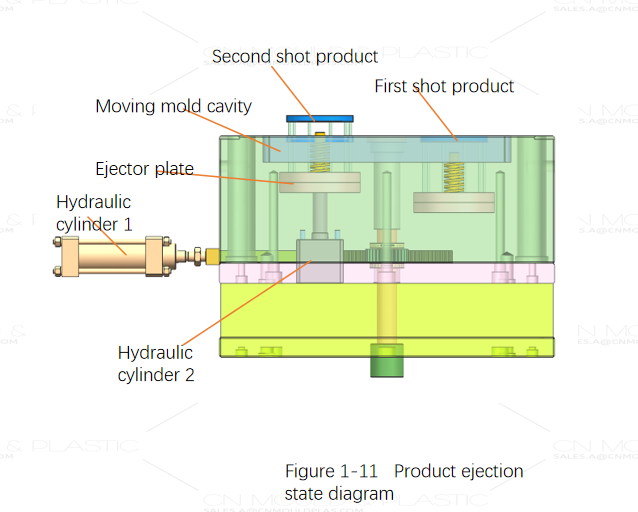

Figure 1-1 shows a two-color product diagram of the internal parts of a household appliance. The product has an average wall thickness of 2.5mm and an overall dimension of ф156mm x 7mm. The green part is made of the first-color ABS material, weighing 28.1g, while the orange part is made of the second-color TPE material, weighing 4.7g. The product features a simple structure and has low requirements for appearance quality. The second-color TPE material of the product is entirely molded in the fixed mold. This product is a typical two-color injection-molded product, and the mold is required to produce 1+1 cavities per mold.

Key Design Points

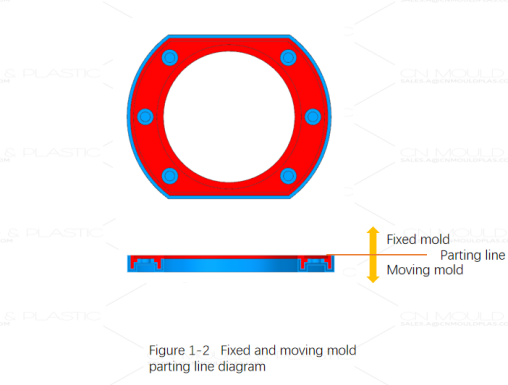

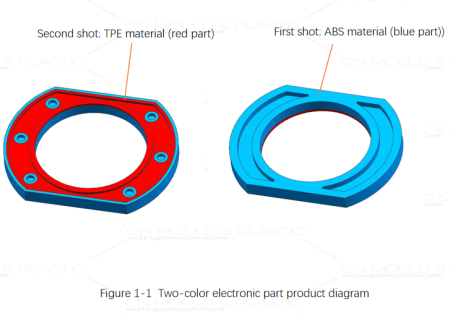

Parting and Mold Opening Direction

The parting surface of this product is very simple, fully complying with the basic principles of simple two-color mold design: the product shape in the fixed mold part is different, while the moving mold part is completely the same. Since the second-color TPE material of the product can all be molded in the fixed mold cavity, the parting surface of the mold is basically a single surface. Given the product’s simple structure, it can be directly molded by the fixed mold and moving mold, as shown in Figure 1-2.

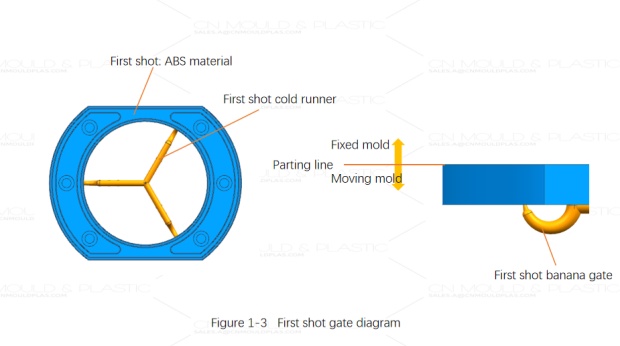

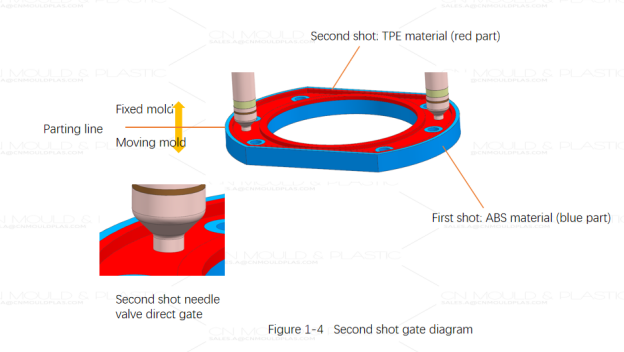

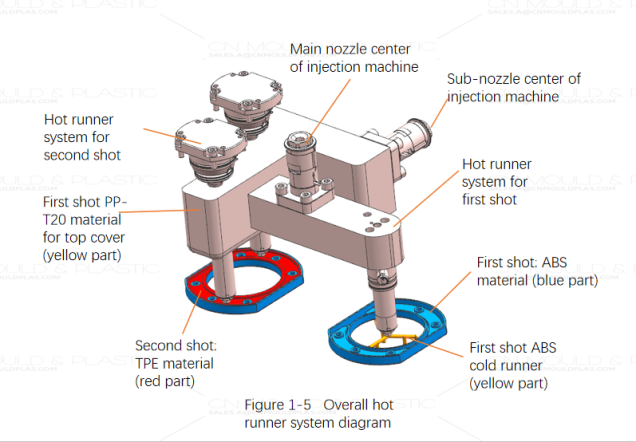

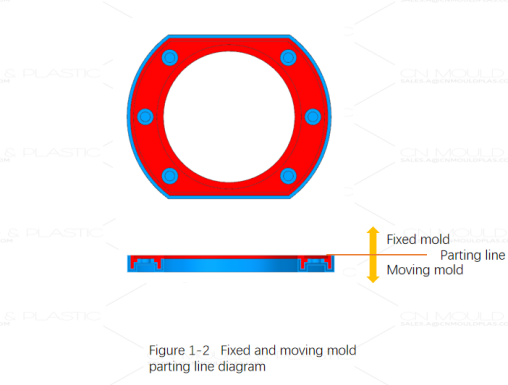

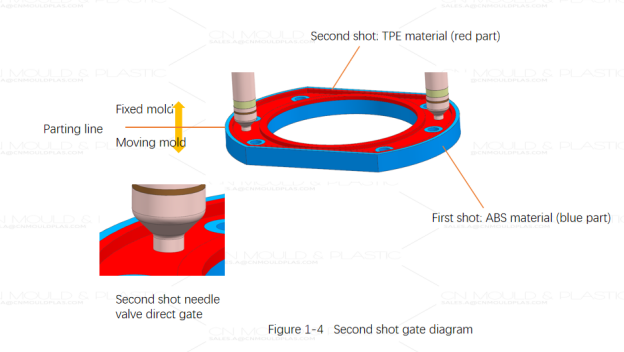

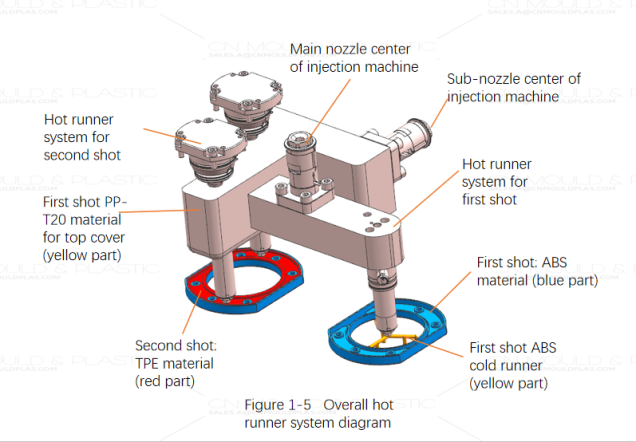

Gate Setting

In the early stage of mold design, an analysis was first conducted on how to feed the material into the mold. The secondary injection nozzle of the injection molding machine matched with this two-color mold is located opposite the operator, and the moving mold of this injection molding machine is not equipped with a rotating workbench. Based on the characteristics of the circular product, the first-color ABS material uses a hot nozzle converted to 3-point banana gates, which can reduce product deformation after injection molding, as shown in Figure 1-3. The second-color TPE material directly uses 2 needle-valve hot nozzles, as shown in Figure 1-4. Figure 1-5 shows the overall runner diagram of the gating system.

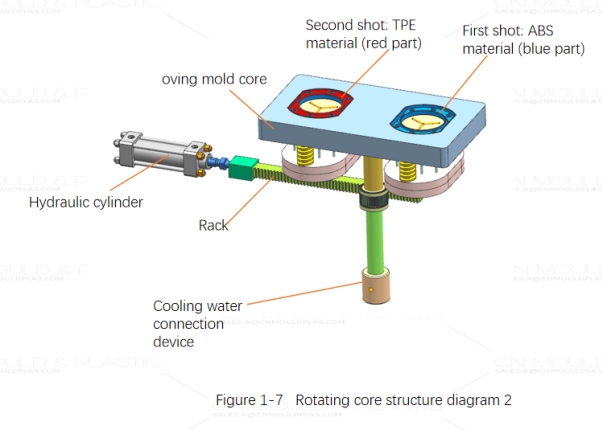

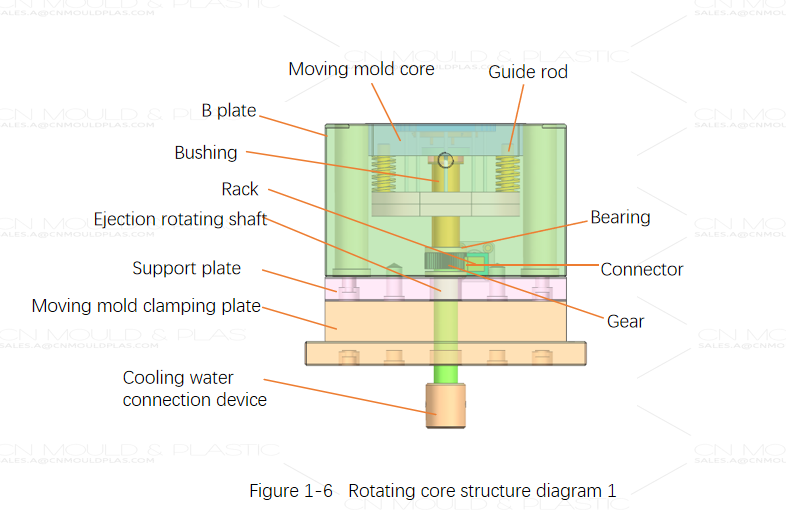

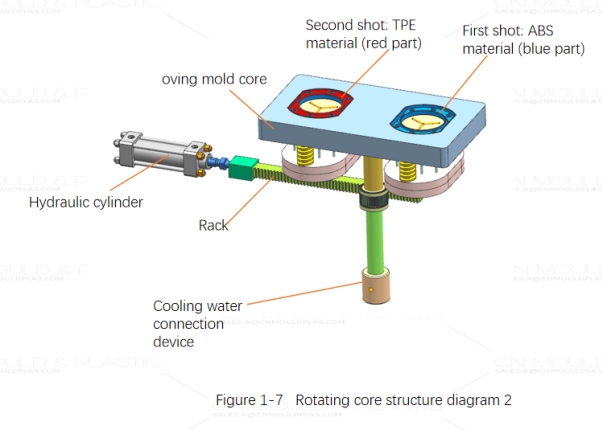

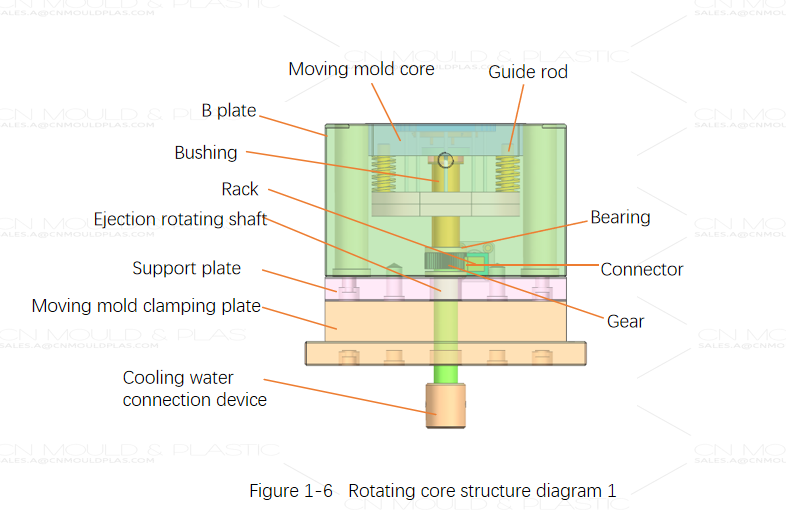

Since the moving mold of the injection molding machine matched with this mold is not equipped with a rotating workbench, this set of molds cannot be designed according to the conventional rotating moving mold. How to realize the function of two-color injection molding with a rotating moving mold when the injection molding machine is not equipped with a rotating workbench? The following introduces a two-color injection molding mold with a rotating moving mold core. Figures 1-6 and 1-7 show the structure diagram of the rotating moving mold core. After the first-color ABS material injection is completed and the mold is opened, the ejection device of the injection molding machine ejects the moving mold core out of the mold base through the ejection rotating shaft. Then, a hydraulic cylinder drives the rack, which in turn drives the gear and the ejection rotating shaft, ultimately rotating the moving mold core by 180°. The moving mold core reaches the second-color injection position, and then the mold closes for the second-color injection. The cooling water for the moving mold core can be connected from the back of the moving mold workbench of the injection molding machine through the ejection rotating shaft and the cooling water connection device.

=

=

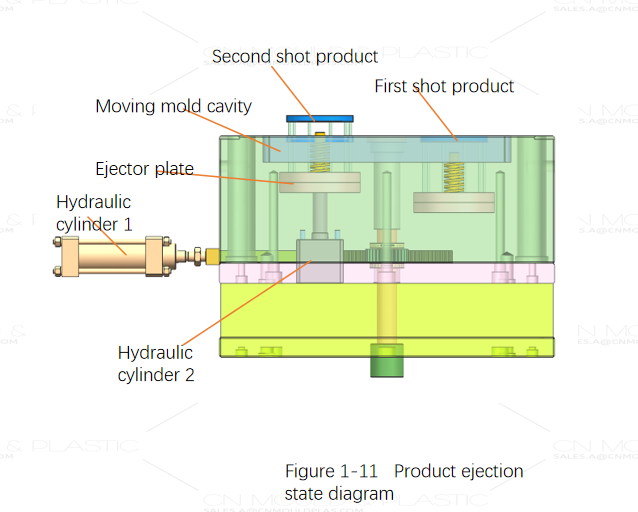

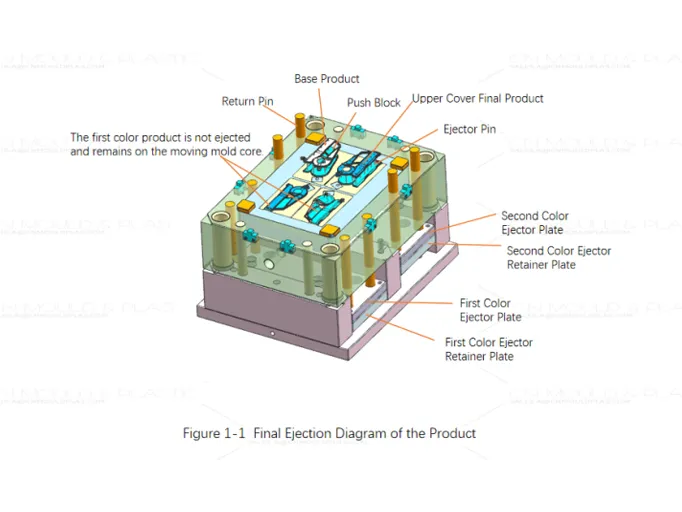

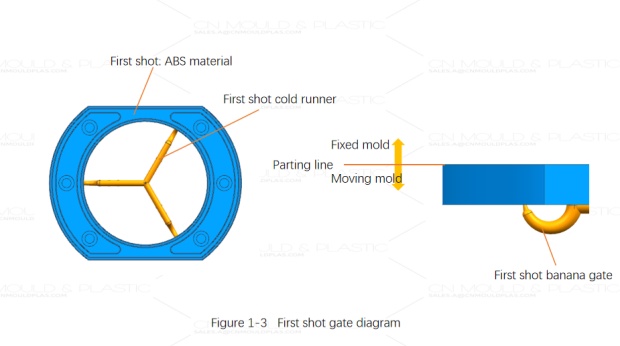

Product Ejection

Although the parting of this mold set is simple, it cannot be ejected directly in the ordinary way. Since the moving mold core of this two-color mold needs to rotate, the ejection of the mold includes two parts: the first part is the ejection and rotation of the rotating moving mold core, and the second part is the ejection of the product and the runner.

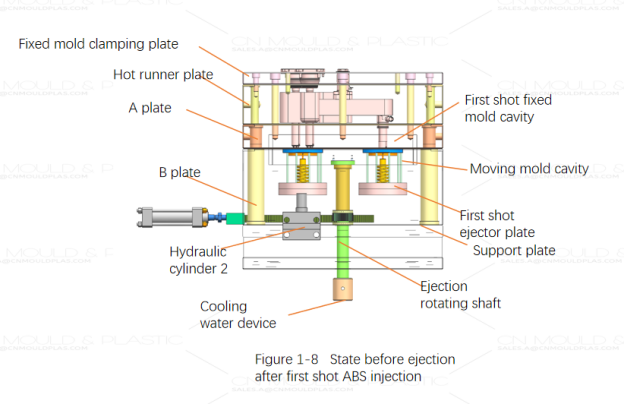

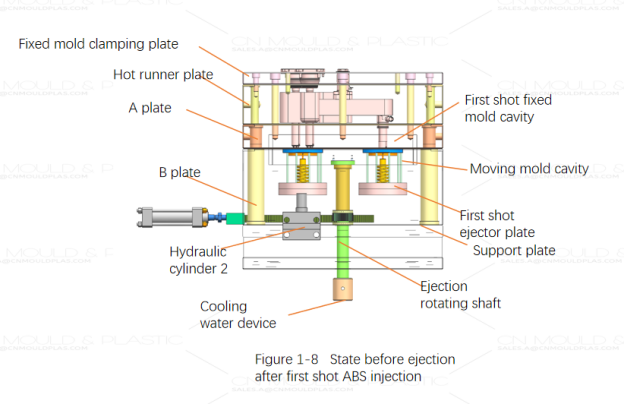

First, analyze the ejection and rotation of the rotating moving mold core. Figure 1-8 shows the state of the moving mold core before ejection after the first-color ABS material is injected.

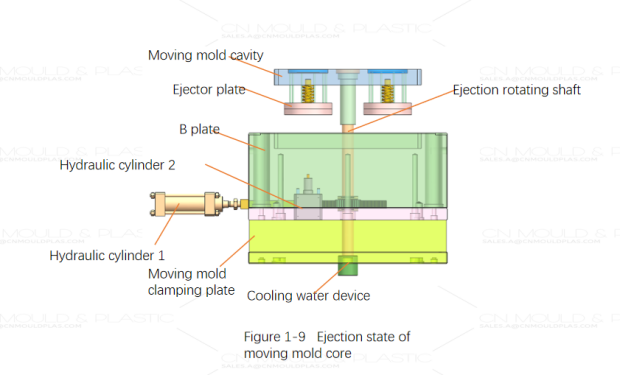

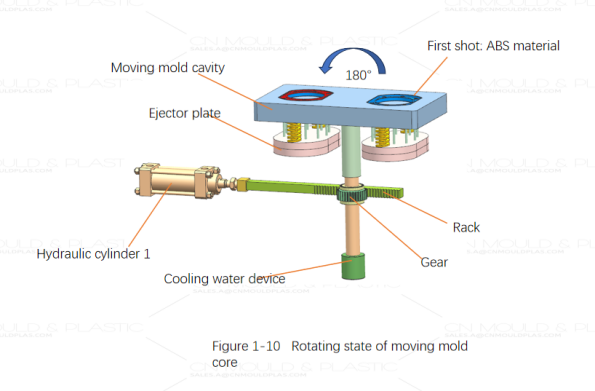

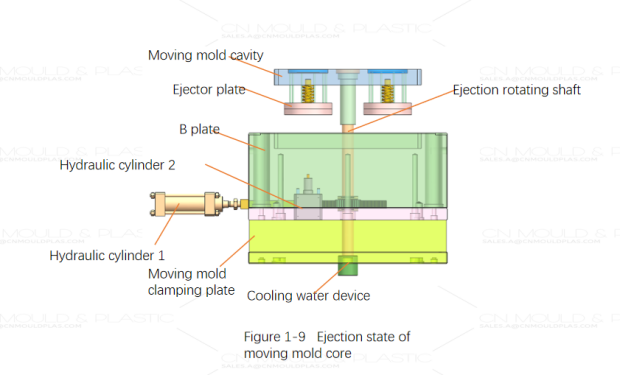

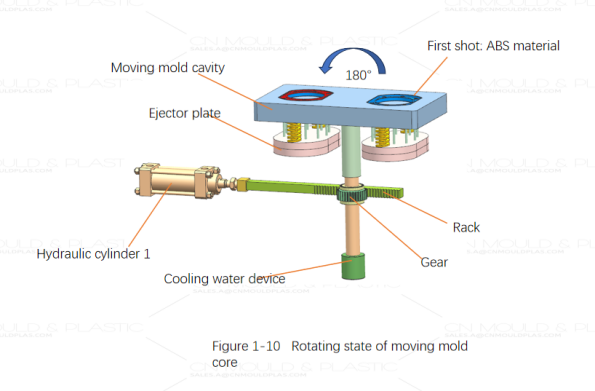

After the injection molding of the first-color product is completed, the mold opens for the first time. The ejection mechanism of the injection molding machine pushes the ejection rotating shaft on the mold to eject the moving mold core, as shown in Figure 1-9. After the moving mold core is ejected, Hydraulic Cylinder 1 starts to work. Through rack and pinion transmission, it drives the ejection rotating shaft to rotate 180°, thereby driving the moving mold core to rotate to the injection molding position of the second-color product, as shown in Figure 1-10.

After the moving mold core rotates to the injection molding position of the second-color product, the ejection mechanism of the injection molding machine pulls the moving mold core back to the mold working position through the ejection rotating shaft. The mold closes to carry out the injection molding of the second-color product. After the injection is completed, the mold opens for the second time. Hydraulic Cylinder 2 starts the ejection action, pushing the ejector plate and ejector retainer plate at the second-color position, and driving the ejector pins to eject the product and the runner, as shown in Figure 1-11.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk

=

=