Product Description

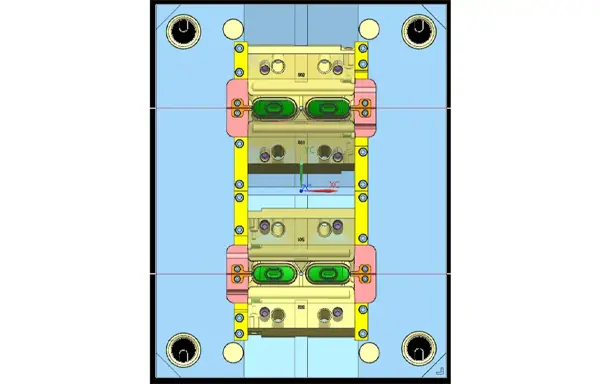

Figure 1-1 shows a two-shot product diagram of two interior automotive components. The average wall thickness is 2.0 mm, with overall dimensions of 113.7 mm × 299.2 mm × 305.3 mm and 177.9 mm × 299.2 mm × 312.1 mm, respectively. The left product is the upper cover, where the green section represents the first material, PP-T20, weighing 131.2 g, and the orange section is the second material, TPE, weighing 12.8 g. The right product is the base, where the blue section is the first material, PP-T20, weighing 143.9 g, and the orange section is the second material, TPE, weighing 13.1 g. The mold is designed to produce 1+1 cavity per cycle, meaning the upper cover and base are molded simultaneously in the same mold. Figure 1-2 shows the assembly of the upper cover and base.

Design Highlights

1.Parting Line and Ejection Direction

The product structure is simple, with no ribs on the fixed or moving sides. The parting line follows the product’s maximum contour. Figures 1-3 and 1-4 show the parting lines for the upper cover and base, respectively.

2.Gate Design

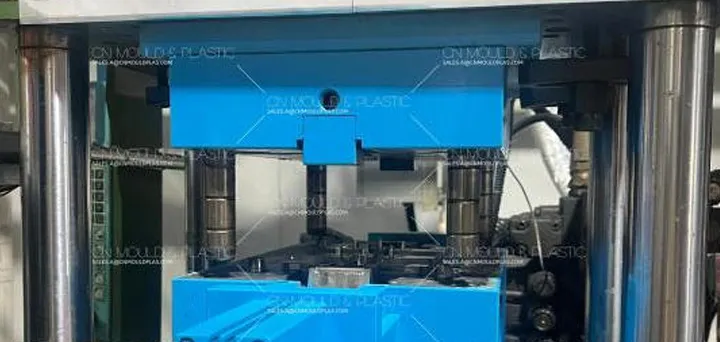

The two-shot injection molding machine used for this mold does not feature a rotary table on the moving side. Instead, a secondary nozzle is added opposite the operator, making it a modified two-shot machine rather than a true dual-color system. This configuration requires a non-conventional mold design.

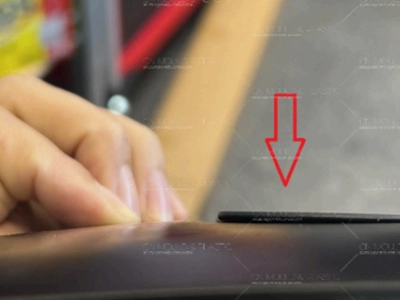

Analysis revealed that the second-shot TPE material is located only at one end of the product, with a regular shape and two notches. A sliding molding component—referred to as a "blade"—was designed. After the first-shot PP-T20 is injected, the blade retracts by a distance equal to the wall thickness, creating a cavity for the second-shot TPE material (see Figure 1-5).

Due to geometric constraints, the blade is only 5 mm thick but relatively long. During the first shot, the blade advances toward the moving mold to form the side wall of the PP-T20 cavity while blocking the TPE cavity. After the first shot, the blade retracts to align with the fixed mold cavity, allowing the TPE cavity to connect with the first-shot cavity. The blade then forms the TPE cavity for the second shot, enabling two materials to be molded in the same cavity without rotation.

The first-shot PP-T20 material for both the upper cover and base is gated via a valve-gated hot nozzle at the center of the product (Figure 1-6). The second-shot TPE is gated through two submarine gates (Figures 1-7 and 1-8).

The mold is configured for an L-type two-shot machine with perpendicular nozzles: the primary nozzle is in the standard position, and the secondary nozzle is opposite the operator. The runner system is shown in Figure 1-9.

3.Molding Sequence with "Blade" Mechanism

The second-shot TPE forms a U-shaped profile, requiring three independently actuated blades to create the cavity. At the intersections of the blades, excess TPE material may form, but since the product is an internal automotive component, this does not affect appearance, function, or assembly. The final design adopts the blade-based approach (Figure 1-10).

Due to undercuts on the side walls, side sliders are incorporated into the moving mold, and the blades are integrated into these sliders. The mold structure is detailed in Figures 1-11 to 1-13.

During the first shot, hydraulic cylinders advance the blades downward to contact the moving mold core (Figures 1-11–1-13). After the first shot, Hydraulic Cylinder 1 (Figure 1-12) actuates the T-blocks to retract the fixed-mold blades to the second-shot position. Simultaneously, Hydraulic Cylinders 2 and 3 (Figure 1-12) retract the moving-mold blades via T-blocks. The mold remains closed during this process. Figures 1-14 and 1-15 show the blades in the second-shot molding position.

4.Product Ejection

Ejection is similar to a standard single-shot mold, using a single ejector plate and support plate. After the second shot, the mold opens, and the machine’s ejector rod pushes the ejector assembly to eject the product and the cold runner of the second shot. Figure 1-16 illustrates the ejection process.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk