① Differentiating between Quality Defects and Action Errors It is often said that it is impossible to guarantee a defect rate of 0, but a rate of 0 self - errors can be guaranteed.

The defect mentioned here (production defect) refers to defects outside the specifications that are "discovered by the respective manufacturer."

Since defects can be discovered and corrected immediately during or after the action, no non - conformities outside the specifications will occur in the subsequent quality inspection.

Take the non - conformities in screw fastening as an example. We refer to the installation of screws as the first - stage project. If Xiao A discovers a defect during the inspection after completing the first - stage project, this defect is called a "production defect." However, if no inspection is carried out and the object is directly submitted for quality inspection, a defect discovered at this stage is regarded as a "quality defect."

② Avoiding Repeated Production Defects From the example of screw fastening in section ①, we know that if a defect is discovered in the first - stage project, it can be corrected in a timely manner, which helps us take countermeasures to avoid the recurrence of the defect.

Of course, if a defect is discovered during the quality inspection, we can also go back to the first - stage project, investigate and identify the cause of the defect, and develop countermeasures.

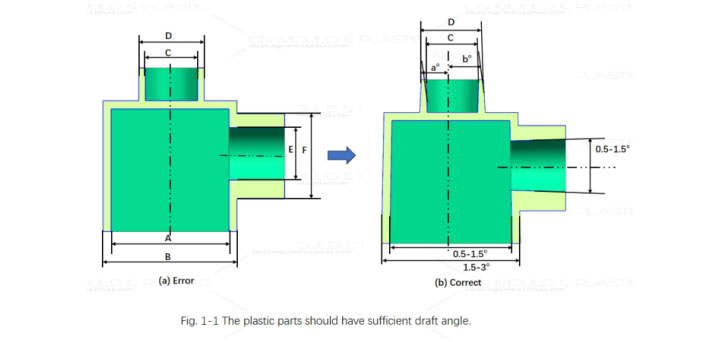

Figure 1 - 1 Differences between Quality Defects and Action Errors

| Quality Defect | Production Error |

| Defects found during quality inspection | Errors found during the production process |

● Defects in Screwing (in the First Process Section)

Phase 1 Engineering | Phase 2 Engineering | Quality Inspection Stage |

Production Error | Quality Defect | Quality Defect |

● Defects in Labeling (in the Second Process Section)

Phase 1 Engineering | Phase 2 Engineering | Quality Inspection Stage |

Production Error | Quality Defect |

Figure 1 - 2 Quality Defects and Production Errors Varying by Phase

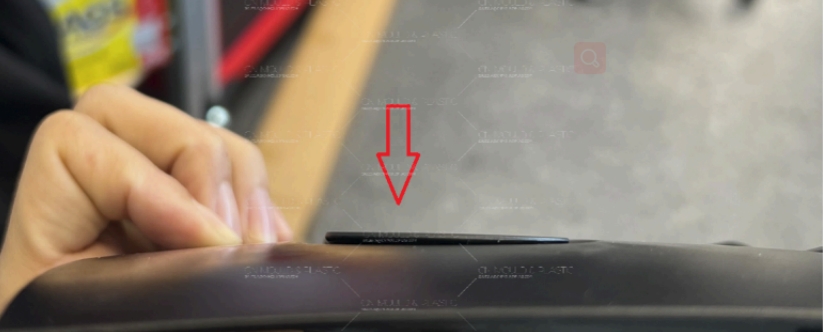

If countermeasures are taken only after the occurrence of defective products, it is already too late. For example, the cause of defective products lies in the "wear of the drill bit." If measures are not taken immediately in the first production section and the drill bit is not replaced, more defective products may be produced. Therefore, it is crucial to identify defects as early as possible and take countermeasures to avoid problems from the start.

For the responsible personnel, differentiating between "production defects" and "quality defects" is of great significance. The principle of "Production starts with inspection and ends with inspection" is an unchanging rule for identifying production defects.