Here are several powerful design strategies that go beyond ribs to create inherently more rigid and stable plastic parts.

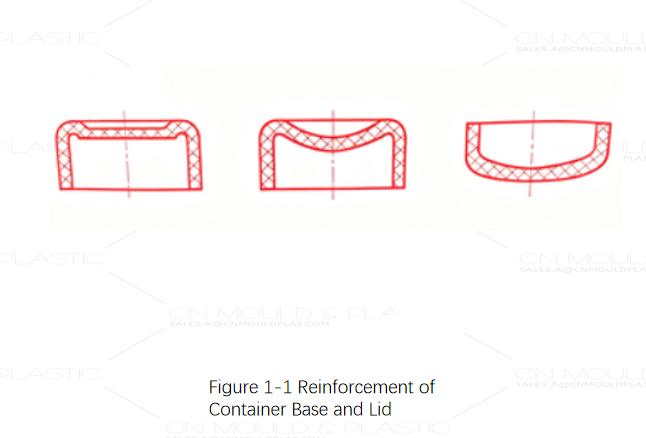

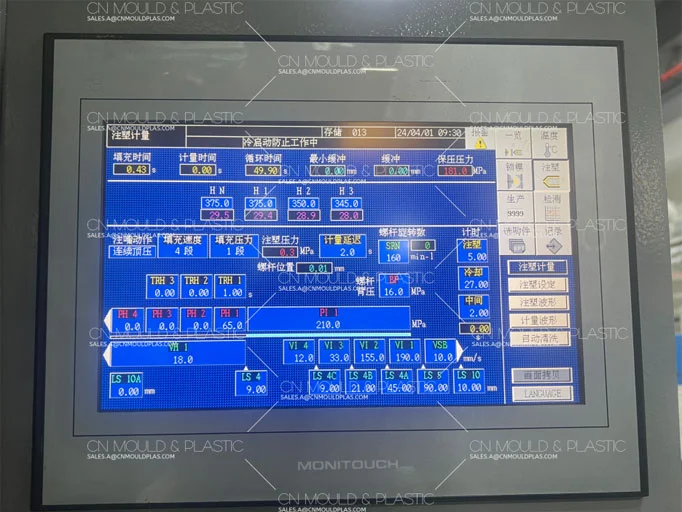

The Power of Curved Surfaces

For large, thin-shelled parts, a flat surface is an invitation to warp. The solution? Replace flatness with curvature.

Concept: Designing the shell as a spherical or arched surface dramatically increases stiffness, much like an eggshell or an arch bridge can support significant load.

Benefit: This shape distributes stress more evenly across the entire surface, effectively resisting bending and deformation forces that would cause a flat panel to warp.

Application: Ideal for large covers, housings, and lids where flatness is not a strict functional requirement.

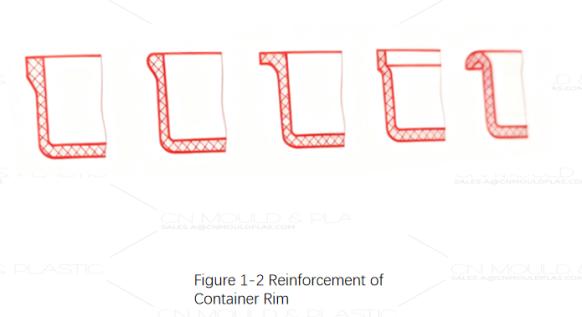

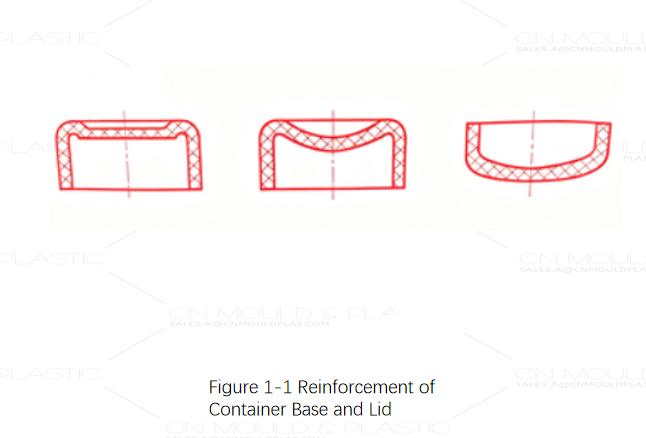

Reinforcing the Weakest Link: Container Edges

The top edge of a thin-walled container is a common failure point for rigidity. A simple rolled lip can transform its stability.

Concept: Adding a curled or thickened rim to the edge of a cup, tub, or enclosure.

Benefit: This acts like a structural hoop, greatly increasing the overall torsional and lateral stiffness of the container and preventing the walls from buckling or deforming.

Application: Perfect for food containers, industrial tubs, and any open-top thin-walled structure.

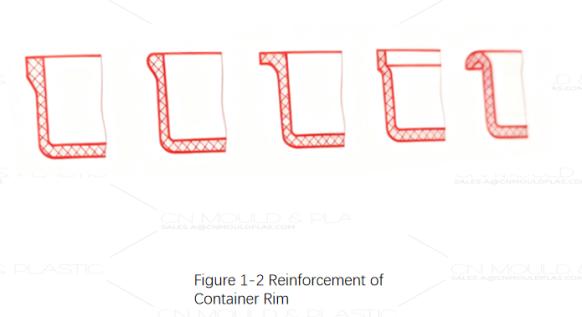

The Optical Illusion: Hiding Deformation in Curves

When using flexible plastics (like PP or PE), rectangular containers are prone to unsightly "caving-in" of the sidewalls. You can't always prevent the material from flexing, but you can design so the flex is invisible.

Concept: Instead of flat sides, design all sides as outward-curving convex arches.

Benefit: When internal negative pressure or shrinkage occurs, the convex panel has room to flex inward slightly without appearing deformed. It simply becomes less curved, avoiding the obvious "dent" of a flat panel.

Application: Excellent for squeeze bottles, flexible storage boxes, and any consumer product where aesthetics are critical.

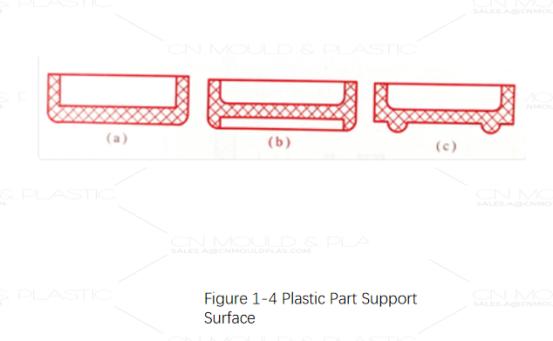

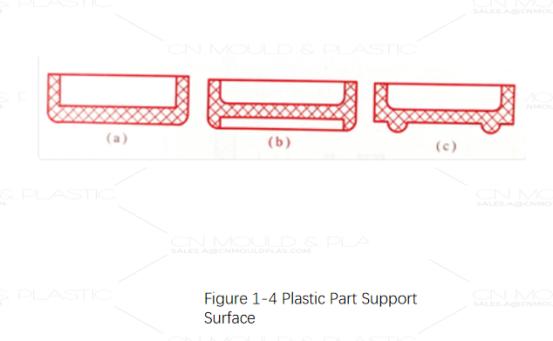

The Foundation: Stable Support Surfaces

Using the entire bottom surface of a part as a support seems logical, but it's a classic design trap. Even minor warping will make the entire structure rock unstable.

The Problem (What NOT to do): A full, flat bottom surface guarantees instability due to inevitable micro-warping and mold shrinkage.

The Solution (What TO do): Use discrete, co-planar support features.

Solution A: Raised Perimeter Bracket: A continuous raised rim around the bottom provides a stable, wide base that is much less susceptible to full-plane warping.

Solution B: Individual Feet: Several small, coplanar feet are the most reliable solution. They are easy to keep flat and compensate for any minor warping in the part's main body

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk