When accepting a commission for die manufacturing, first of all, according to the part drawing of the product or the actual object, analyze and study the number of sets of dies to be used, the die structure and the main processing methods. Then, estimate the price of the die. The contents of the estimation include:

(1) Die cost refers to material cost, cost of purchased parts, design cost, processing cost, assembly adjustment and die trial cost, unforeseen cost, etc. When necessary, also estimate the tools used in various processing methods and their processing costs, etc. Finally, obtain the manufacturing price of the die.

(2) Delivery time Estimate the time to complete each task and determine the delivery time.

(3) Total life of the die Estimate the single life of the die and the total life after multiple simple repairs (that is, the natural life of the die without accidents).

(4) Product material The performance, size, consumption and utilization rate of the materials specified for the product.

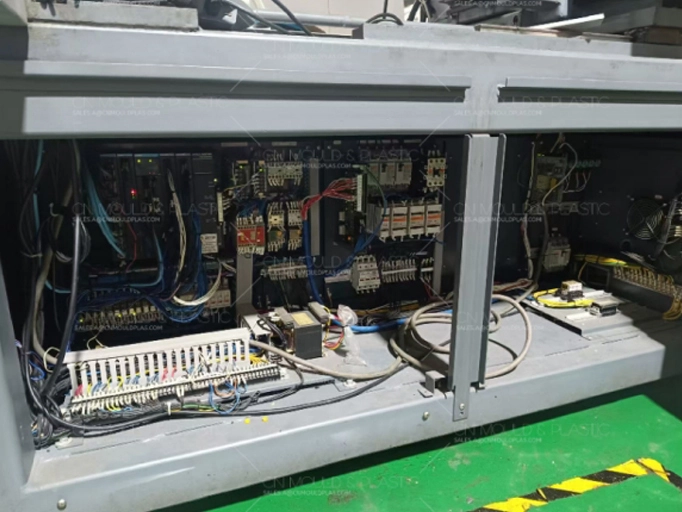

(5) Equipment used: Understand the performance, specifications, and auxiliary equipment of processing machines (e.g., double injection molding machine)

When estimating the price of the die, it is not enough to only pay attention to the die price and the delivery time. An excellent die technician should have a full understanding and estimation of the possible problems in the die manufacturing and die trial process, as well as the usage situation after the die is made. At the same time, unforeseen situations should also be considered.

1)Dynamic and Static Precision of the Die

The precision of mechanical products includes dimensional precision, shape precision and mutual position precision. The precision of mechanical products in the working state and non-working state is respectively called dynamic precision and static precision.

The precision of the die is mainly reflected in the precision of the working parts of the die and the matching precision of the relevant parts. The precision of the working part of the die is higher than that of the product part. For example, the precision of the cutting edge size of the blanking die is higher than that of the product part. The numerical value and uniform consistency of the blanking clearance between the blanking punch and the die are also one of the main precision parameters. The precision measured usually is carried out in the non-working state, such as the blanking clearance, that is, the static precision. When in the working state, affected by the working conditions, the values of the static precision change, which is called dynamic precision at this time, and this dynamic blanking clearance is really meaningful. Generally, the precision of the die should also be coordinated with the precision of the product part, and is also restricted by the die processing technical means. In the future, with the improvement of die processing technical means, the precision of the die will be greatly improved, and the interchangeable production of the working parts of the die will become a reality.

The main factors affecting the precision of the die are:

① Precision of the product part The higher the precision of the product part, the higher the precision of the working parts of the die. The precision of the die not only has a direct impact on the precision of the product part, but also has a great impact on the production cycle and production cost of the die.

② Level of die processing technical means How about the processing precision of the die processing equipment and the degree of automation of the equipment are the basic conditions for ensuring the precision of the die. In the future, the precision of the die will depend more on the level of die processing technical means.

③ Technical level of die assembly fitters The final precision of the die depends to a large extent on the assembly and debugging. The surface roughness value of the finishing surface of the die mainly depends on the die fitters. Therefore, the technical level of die fitters is an important factor affecting the precision of the die.

④ Production mode and management level of die manufacturing Whether the working edge size of the die is processed by the "matching method" or the "separate manufacturing method" in die design and production is an important factor affecting the assembly precision of the die. For high-precision dies, only the "matching method" can meet the requirements of high precision.

2)Rigidity of the Die

For high-speed stamping dies, stamping and forming dies for large parts, precision plastic dies and large plastic dies, not only high precision is required, but also good stiffness is necessary. The working load of this kind of dies is relatively large. When there is a large elastic deformation, it will not only affect the dynamic precision of the die, but also be related to whether the die can continue to work normally. Therefore, in die design, while meeting the strength requirements, the stiffness of the die should also be ensured. At the same time, additional deformation caused by improper processing should be avoided during manufacturing.

3)Production Cycle of the Die

The production cycle of the die is the time from accepting the die order task to delivering the qualified die after die trial and identification. At present, the die using units require a shorter and shorter production cycle of the die to meet the needs of market competition and renewal. Therefore, the length of the die production cycle is one of the comprehensive signs to measure the production capacity and technical level of a die enterprise, and is also related to whether a die enterprise can gain a foothold in the fierce market competition. At the same time, the length of the die production cycle is also a sign to measure the technical management level of die in a country.

The main factors affecting the production cycle of the die are:

① Standardization degree of die technology and production The standardization degree of die is the product of the development of die technology and production in a country to a certain level. At present, the standardization of die technology in China has a good foundation, including die basic technical standards, various die design standards, die process standards, die blanks and semi-finished parts standards, as well as die inspection and acceptance standards, etc. Due to the situation of "small but complete" and "large but complete" of Chinese enterprises, the commercialization degree of die standard parts is still not high, which is an important factor affecting the die production cycle.

② Specialization degree of die enterprises The development trend of modern industry is that the division of labor of enterprises is getting finer and finer. The higher the specialization degree of enterprise products, the better the product quality and economic benefits can be improved, and it is also beneficial to shorten the product production cycle. At present, the specialization degree of die enterprises in China is still relatively low. Only when each die enterprise produces the die type it is best at, has a clear and fixed service scope, and at the same time, each die enterprise cooperates with each other for collaborative production, can the die production cycle be shortened.

③ Modernization of die production technical means The modernization of die design, production and detection means is also one of the factors affecting the die production cycle. The CAD/CAM technology of dies must be vigorously promoted and popularized, so that the rough machining can develop towards high efficiency. High-efficiency equipment such as high-speed sawing machines, anodic cutting and grinding wheel cutting are used for blanking; high-speed milling machines and powerful high-speed grinding machines are used for rough machining; high-precision numerical control machine tools, such as numerical control copying milling machines, numerical control optical curve grinding machines, high-precision numerical control electrical discharge wire cutting machine tools, numerical control continuous path coordinate grinding machines, etc., are used for precision machining, and advanced and rapid die manufacturing technology is also promoted.

④ Operation and management level of die production Efficiency should be pursued in management. Studying the laws and characteristics of die enterprise production and using modern management means and systems to manage the enterprise are also important factors affecting the die production cycle.