1. Mold Manufacturing Cycle Control

The mold delivery date, that is, the delivery period, is one of the main contents clearly specified in the user contract, and it is also a main indicator reflecting the production capacity and level of the mold enterprise. Because the delivery period depends on the mold production cycle, that is, it depends on the mold design time and mold manufacturing time, and the mold manufacturing time, namely the manufacturing cycle, is the most crucial and important stage in the delivery period. Therefore, in the mold production process, on the basis of ensuring the manufacturing accuracy and quality of the mold, controlling and ensuring the mold manufacturing cycle is the most important task of the enterprise, which depends on the following aspects:

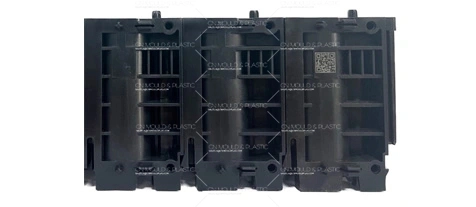

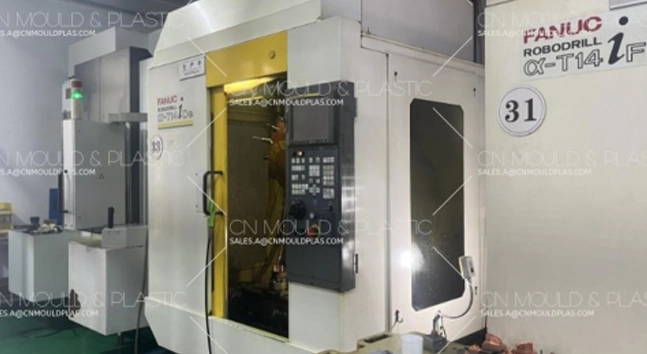

1) Advanced and Matching Production Equipment of the Enterprise: This is the technical basis for ensuring the manufacturing cycle and the manufacturing accuracy and quality of the mold, and it is a necessary condition for formulating the mold manufacturing process regulations.

2) Production Planning: Molds are produced as single - piece items. To ensure and control the mold manufacturing cycle, it is necessary to emphasize formulating production plans based on individual molds. The mold production plan includes:

Master Plan: A plan with a quarterly, semi - annual, or annual time limit. It is a plan formulated according to the user contract.

Sub - plan: A plan with a monthly time limit, also known as a monthly plan. It is a plan formulated based on the master plan.

Operation Plan: A plan formulated based on the monthly mold production plan and the manufacturing process regulations of individual molds.

To ensure the completion of the mold production plan, it is necessary to emphasize the control and management of the manufacturing process regulations for each mold, that is, to emphasize the control and management of key links or the quality and completion time limits of each process.

3) Standardization of Manufacturing Cycle Control and Management: Standardization includes the application of standardized documents and charts. Computer-aided control and management refer to internal digital information systems for overseeing mold production processes, manufacturing regulations, and plan formation— adopted by China mold maker to improve efficiency.

2. Control of Mold Production Costs

The mold price is clearly specified in the user contract. The mold price is composed of the following five parts, namely:

1)Mold design and manufacturing costs.

2)Costs for purchasing mold materials and standard parts.

3)Production management fees.

4)Technical surcharges.

5)Taxes (including value - added tax and income tax).

The mold design and manufacturing costs are directly proportional to the man - hour costs. Moreover, the profits, wages, welfare benefits, and taxes of the mold enterprise all depend on the value created by mold design and manufacturing. Therefore, improving mold production efficiency and shortening the design and manufacturing periods are the most crucial measures and approaches for controlling costs, reducing production costs, and improving the economic benefits of the mold enterprise.

Molds, as specialized technological equipment with a long service life, have the following production characteristics:

(1) Single - piece and multi - variety production

Molds are specialized technological equipment with a long service life. Each set of molds can only produce parts with a specific shape, size, and precision. This determines that mold production belongs to the nature of single - piece and multi - variety production.

(2) The development of mold processing towards mechanization, precision, and automation

Currently, product parts have increasingly higher requirements for mold precision, and there are more and more molds with high precision, long service life, and high efficiency. The machining precision mainly depends on the precision of the machining machine tools, machining process conditions, measurement means, and methods. At present, precision forming grinding machines, CNC high - precision surface grinding machines, precision CNC wire electrical discharge machining machines, high - precision continuous - path coordinate grinding machines, and three - coordinate measuring machines are being used more and more commonly, enabling mold processing to develop towards a high - technology - intensive direction.

(3) Short mold production cycle is objectively required

Currently, due to the accelerated pace of new product updates and increased market competition, there is an objective requirement for an increasingly shorter mold production cycle. The production management, design, and technology of molds should all adapt to this objective requirement.

(4) Completeness of mold production

When a certain part requires multiple sets of molds for processing, these sets of molds are often interrelated and affect each other. Only when the final part is qualified can the entire set of molds be considered qualified. Therefore, this characteristic must be fully considered in production and planning arrangements.

(5) Mold trial and adjustment

Due to the above - mentioned characteristics of mold production and the empirical nature of mold design, after assembly, molds must undergo trial stamping or trial pressing to finally determine their qualification. At the same time, some parts need to be trial - repaired before final determination. Therefore, a certain mold trial period must be reserved in the production schedule.

Technological characteristics of molds

Due to the generally low technical means of mold processing in China, as well as the above - mentioned production characteristics, the main technological characteristics of mold manufacturing in China are currently as follows:

1). In mold processing, universal machine tools, general - purpose cutting tools, fixtures, measuring tools, and instruments should be used as much as possible to minimize the number of special secondary tools.

2). In mold design and manufacturing, methods such as "fitting method" and "simultaneous boring method" are often used, which reduces the interchangeability of mold parts. However, these are effective measures to ensure machining precision and reduce machining difficulty. In the future, with the improvement of processing technical means, the degree of interchangeability will definitely increase.

3). In the arrangement of manufacturing processes, processes are relatively concentrated to ensure the processing quality and progress of molds, simplify management, and reduce process turnover time.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk