In an ideal world, a well-designed and properly manufactured mold could, theoretically, last forever. If we eliminate human error, operational mishaps, poor maintenance, and pure accidents, the mold's service life becomes indefinite. It's a fascinating concept that highlights the core of durability in tooling.

Yet, there's a curious gap in our industry. While general engineering and machinery manufacturing have largely embraced rigorous methods, the mold-making sector often still relies on an intuition-based approach, or "going with the feel." Transitioning fully to established engineering principles and calculations is a slow but necessary evolution. The reality is that most mold failures are not mysterious; they stem from identifiable and preventable causes.

The dream of infinite lifespan shatters when faced with these common engineering and procedural shortcomings:

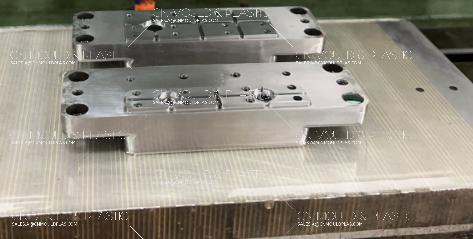

1. Insufficient Part Strength: Critical mold components sometimes lack the strength to withstand the relentless forces they face: clamping force, injection pressure, ejection force, and stresses from differential thermal expansion.

2. Incorrect Material Selection: Choosing a steel grade unsuitable for the specific application, plastic material, or expected production volume is a fundamental error that predetermines a short lifespan.

3. Overlooked Fatigue Strength: This is a major yet frequently ignored cause of mold cracking. Molds endure cyclic loading (clamping/injection) and unloading (opening/ejection). Ignoring the steel's allowable fatigue strength for this pulsating stress leads to catastrophic failure.

4. Improper Heat Treatment: Flaws in the hardening, tempering, or stress-relieving processes can create a brittle core, soft surfaces, or internal stresses, making the steel prone to cracking or wear.

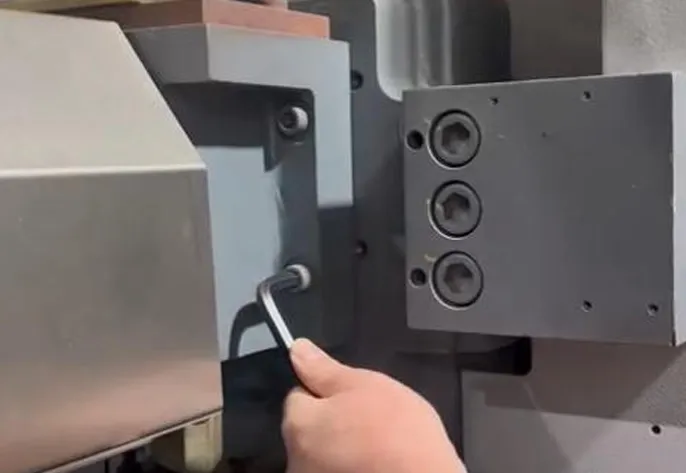

5. Inadequate Lubrication of Moving Parts: Slides, lifters, and ejector systems suffer accelerated wear and galling without proper, regular lubrication, leading to seizure and damage.

6. Improper Machine Setting: Excessive clamping force, uneven platen parallelism, or incorrect injection speeds/pressures can impose abnormal loads on the mold structure.

7. Poor Operational & Maintenance Practices: Perhaps the most variable factor. Technicians bypassing startup/shutdown protocols cause immense harm. Examples include:

Leaving gates mechanically open to prevent freeze-off, exposing delicate components to impact.

Servicing hot runner nozzles or heaters without following strict safety and procedure guidelines.

Failing to perform routine cleaning and preservation, especially after running corrosive materials.

Even a perfectly engineered mold can be undermined by production environment and material factors:

Contaminated or Corrosive Plastics: Impurities, certain flame retardants, or acidic breakdown products attack the steel surface.

Abrasive or Corrosive Fillers: Materials like glass fiber, minerals, or some pigments act like sandpaper, eroding flow channels, gates, and cavities.

High Humidity: Promotes condensation and rapid corrosion on mold surfaces, particularly during non-production periods.

Poor Cooling Water Quality: Dirty, scaled, or corrosive water blocks channels, reduces efficiency, and attacks the mold from the inside out through pitting and corrosion.