In injection molding, the thickness of ribs is more than just a design detail—it can significantly affect how a part cools, shrinks, and ultimately, whether it warps. Understanding this relationship is key to designing molds that produce flat, stable parts.

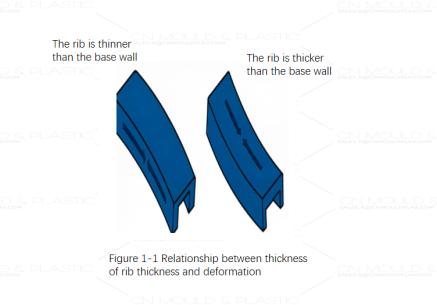

In materials where shrinkage is relatively uniform in both the flow and cross-flow directions, thinner ribs tend to cool and solidify earlier than the main wall. Because they shrink less than the thicker base wall, the ends of these ribs may pull away, causing warpage away from the rib side (as shown in Figure 1-1).

As rib thickness increases and approaches the base wall thickness, this type of warping usually decreases. However, when the rib becomes as thick or even thicker than the base wall, the situation can reverse: the rib ends may now warp toward the rib side. To counteract this, adding extra cooling on the rib side of the mold can help balance the increased thermal load from the thicker rib.

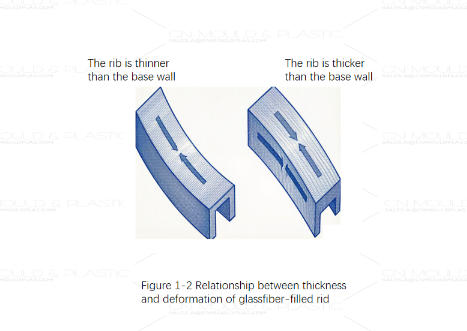

For glass-fiber filled materials, which often shrink more perpendicular to the flow direction than along it, rib thickness plays a different role (see Figure 1-2). Here, thinner ribs tend to fill from the bottom up rather than along their length, leading to higher cross-flow shrinkage. This can cause the rib ends to warp toward the rib itself.

As rib thickness increases, the flow direction becomes more aligned with the rib’s length, reducing this effect. Interestingly, when rib thickness exceeds the base wall thickness, the warping behavior may flip again.