The use of metal inserts in plastic injection molding enhances part functionality but introduces design challenges. Poor insert design can lead to defects like cracks, warpage, or failure. This post outlines six key principles to ensure robust and reliable insert integration.

Optimize Shape for Uniform Shrinkage

Inserts should ideally be circular or symmetrical. This shape promotes uniform plastic shrinkage around the insert during cooling, minimizing residual stress and warpage.

Ensure Adequate Wall Thickness

The different thermal expansion and shrinkage rates of metal and plastic create significant stress at their interface.

A thicker plastic wall around the insert acts as a buffer, reducing the risk of cracking.

A sufficient layer of plastic must also cover the top of the insert to prevent surface defects like sink marks or exposure.

Incorporate Chamfers on the Insert

The embedded edges of the insert should feature chamfers (angled cuts). This simple step is crucial for reducing stress concentration points in the surrounding plastic as it cools and contracts.

Provide Secure Positioning in the Mold

The insert must be firmly and precisely located within the mold cavity.

During injection, high-pressure melt flow can displace or deform a poorly secured insert.

Plastic can also seep into the insert's internal features (e.g., holes, threads), rendering them unusable.

Pro Tip: For small internal thread inserts (below M3) and lower injection pressures, inserting them onto a smooth pin in the mold can simplify the process. While minor plastic flash may enter the threads, it often does not hinder functionality and greatly eases assembly.

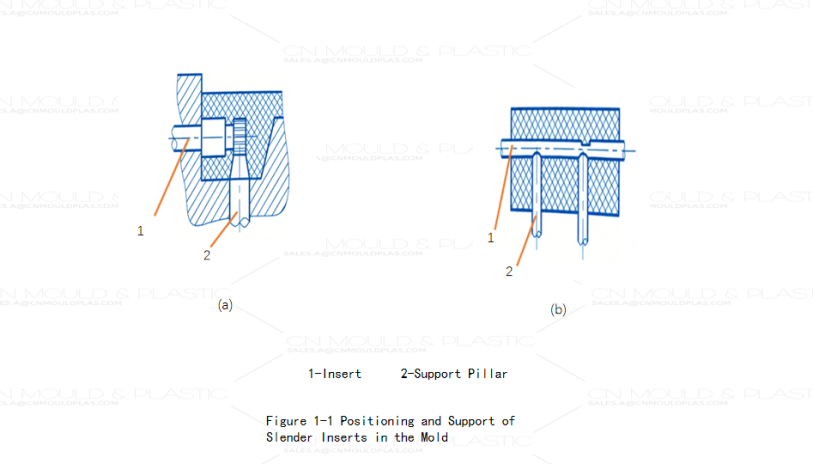

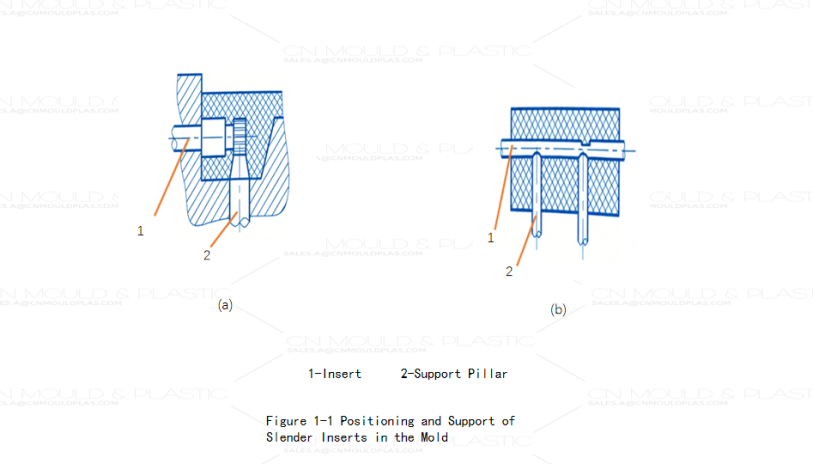

Limit Unsupported Length to Prevent Bending

The free-standing length of an insert should generally not exceed twice its diameter. For longer projections, support pillars must be designed into the mold to prevent bending under injection pressure. Note that pillars will leave a corresponding hole in the final part, so this feature must be placed in a non-critical area. (See Figure 1-1 for an illustration of this support mechanism.)

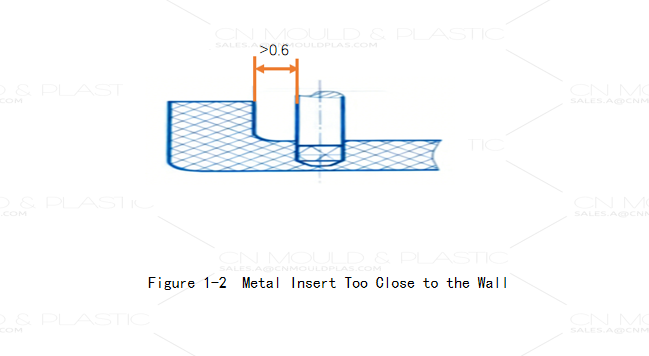

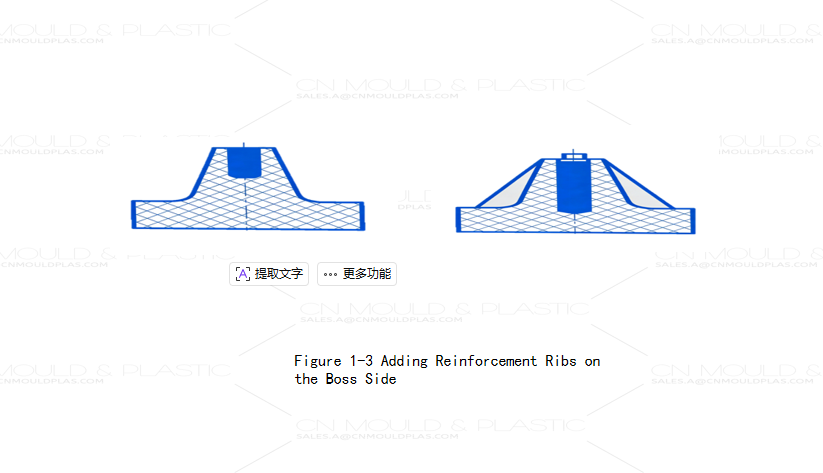

Strategize Placement Near Walls or on Bosses

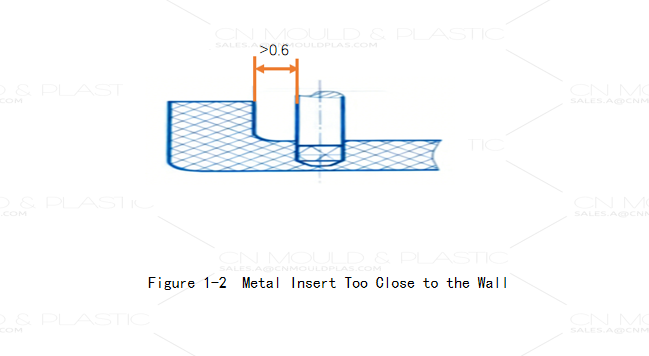

Placing an insert too close to a mold wall complicates machining the locating hole and can weaken the mold structure.(Refer to Figure 1-2)

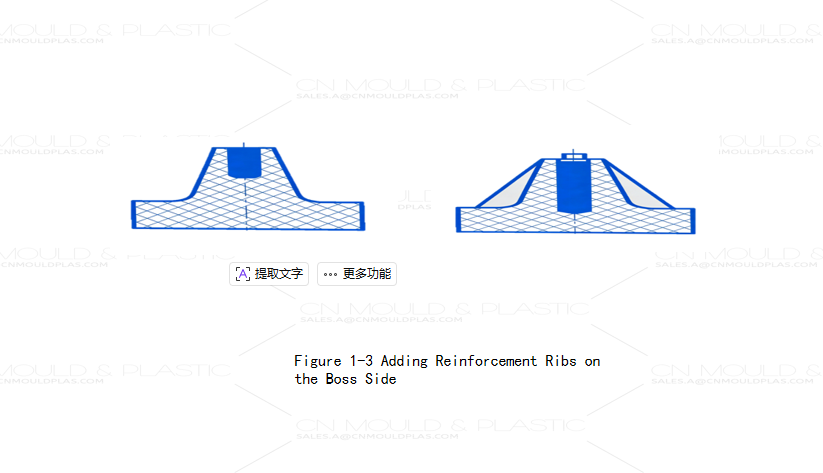

When an insert must be placed on a boss (a raised feature), adding reinforcement ribs to the side of the boss is highly recommended. This strengthens the local area and improves material flow. (Refer to Figure 1-3 for a visual example.)

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk