In the world of plastic part design, bosses are unsung heroes. These often-small features play a critical role in assembly, providing secure points for screws, threaded inserts, and other fasteners to bring components together. But a poorly designed boss can lead to a host of manufacturing and product failure issues. Let's dive into the key principles for designing bosses that are both functional and manufacturable.

At its core, a boss is a cylindrical protrusion designed with a hole to receive a fastener. Beyond just connecting parts, a well-designed boss system enhances overall structural rigidity. A fundamental rule for bosses and any thick sections in plastic parts is to core them out—hollow out the interior—to prevent sinking and reduce material usage. Furthermore, connecting bosses to adjacent side walls with ribs (when possible) improves material flow during injection molding and significantly boosts the boss's strength.

Getting the dimensions right is the first step to a successful boss. Based on extensive design and assembly experience, a reliable rule of thumb is:

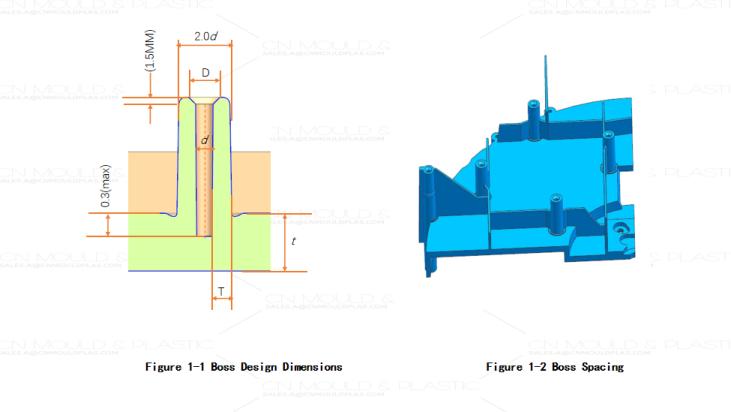

Outer Diameter: The boss's outer diameter should be 2.0 to 2.4 times the outer diameter of the screw or insert it will house. This ratio ensures adequate material around the fastener for strength without creating overly thick sections that are prone to defects. More detailed dimensional guidelines are summarized in Fig. 1-1.

Boss Spacing: When a part requires multiple bosses, their placement is crucial. Bosses placed too close together create thin walls of plastic between them, which are difficult to cool and can become weak points. This affects both part quality and production cycle times. As shown in Fig. 1-2, ensure the spacing between bosses is at least twice the nominal wall thickness of the part. This prevents cooling issues, warpage, and short mold life associated with thin, hard-to-cool areas.

Draft angles are non-negotiable for manufacturability. Applying an appropriate draft to the boss's outer walls allows the part to eject cleanly from the mold.

Outer Walls: A minimum draft of 0.5° is recommended on the outer diameter. Insufficient draft causes the part to scrape and drag during ejection, leading to visible scratches on the part and accelerated wear on the expensive mold tooling.

Inner Walls (Hole): The inside of the boss hole also needs draft. Apply at least 0.25° of draft to the hole's walls to lower the risk of the boss getting damaged or sticking to the core pin during ejection.

While tall bosses might sometimes be necessary, they introduce challenges. A tall, drafted boss naturally becomes thicker at its base, creating a heavier cross-section that cools slowly. This can extend cycle times and potentially affect the precision of the hole's dimensions due to uneven core cooling. As a general guideline, try to keep the height of a boss less than 3 times its outer diameter. If a taller boss is required, careful attention must be paid to cooling and potential sink marks.