Holes are essential features in plastic parts, serving various purposes such as assembly, communication, decoration, and more. Common types include through holes, blind holes, stepped holes, special-shaped holes (complex geometries), and threaded holes. However, due to the significant shrinkage that occurs around holes—often much greater than in other areas of the part—special attention must be paid to design details like draft angles and shrinkage compensation.

To maintain part strength, holes should be placed in areas that do not critically weaken the structure. Sufficient spacing must be ensured between holes and between holes and side walls. When two adjacent holes differ in size, the spacing should be based on the smaller diameter. Both the minimum diameter and maximum depth of holes should be limited according to material and process capabilities. For load-bearing or fastener holes, adding a reinforcing rib or boss around the hole is recommended to enhance strength.

Through Holes

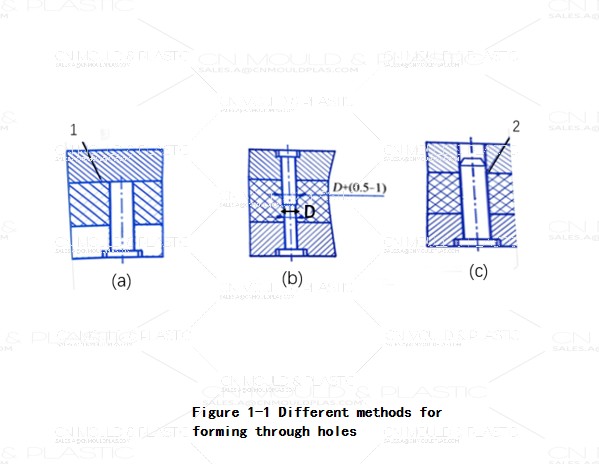

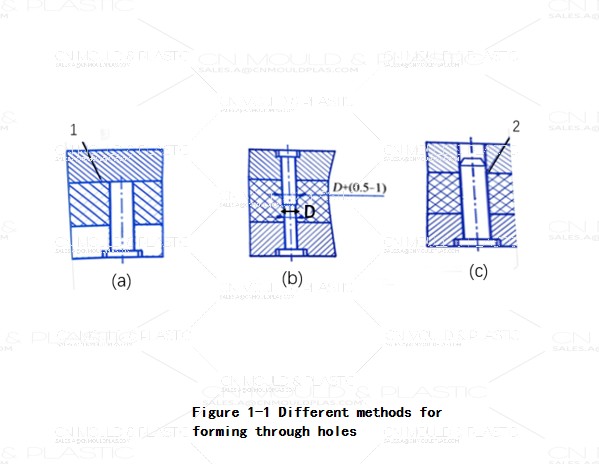

Core pins used to form through holes are typically installed in one of the following ways, as shown in Figure 1-1.

Figure 1-1(a): One-end fixed core pin.

This method is simple but can produce hard-to-trim flash on the parting line. Deep holes or small-diameter holes may cause the core pin to bend.

Figure 1-1(b): Two one-end fixed core pins with a diameter difference of 0.5–1 mm.

This approach reduces each pin’s length by half, improving stability. It is suitable for deep holes where high precision is not critical, as minor misalignment won’t affect assembly or function.

Figure 1-1(c): One-end fixed, one-end guided and supported.

This offers better strength, rigidity, and alignment for the core pin, making it a common choice. However, wear in the guiding section can lead to longitudinal flash around the hole. Regardless of the fixing method, hole depth should be limited to prevent core pin bending.

Blind Holes

Blind holes are formed by a core pin fixed at one end only. As a result, their depth should be less than that of through holes. For injection molding, a general rule is to keep the depth within 4 times the hole diameter.

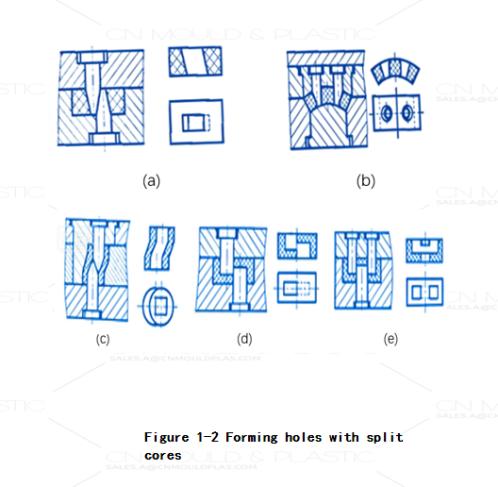

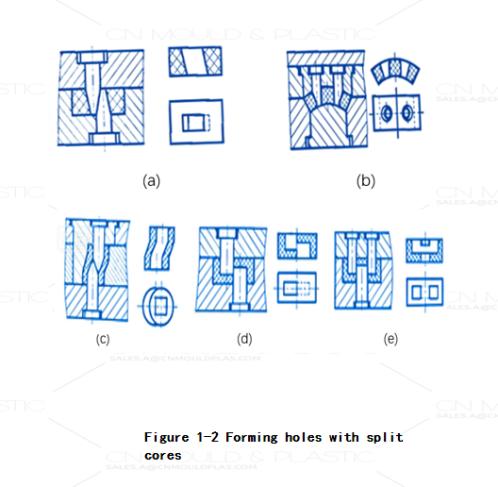

Special-Shaped Holes

For non-round holes, such as angled or complex-profile holes, a split-core design is often used instead of side-action cores. This simplifies mold construction and avoids the need for side core pulling. Figure 1-2 shows several typical examples of such designs.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk