The mechanical drive system is a core component of various industrial equipment, and its stable operation directly impacts production efficiency and equipment lifespan. However, various failures inevitably occur during actual use. This article categorizes common faults, outlines potential causes and solutions, and assists maintenance personnel in quickly identifying issues and taking effective measures.

The linkage mechanism bears significant loads within the drive system. Common issues include:

Wear or Fracture of Linkage Components

Possible Cause: Prolonged operation under high load or material fatigue.

Solution: Replace damaged parts promptly.

Seized or Stiff Linkage Pins

Possible Cause: Corrosion or inadequate lubrication .

Solution: Remove corrosion and enhance lubrication maintenance.

Excessive Clearance between Crosshead and Balance Bar

Possible Cause: Wear leading to increased fitting clearance.

Solution: Replace worn components.

Loose Balance Bar or Mold Clamping Cylinder Piston Rod Nut

Possible Cause: Vibration or insufficient fastening.

Solution: Re-tighten and conduct regular inspections.

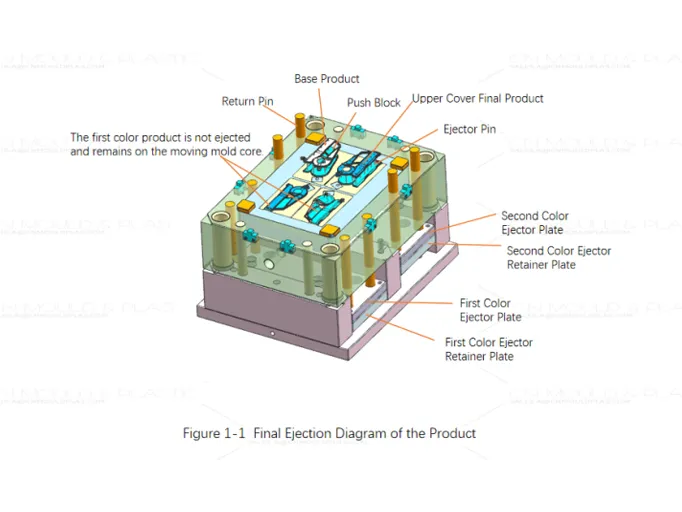

Jammed Ejection Mechanism

Possible Cause: Foreign object intrusion or poor lubrication.

Solution: Clean and repair the adjustment mechanism, ensuring smooth lubrication.

Abnormal Noises in Injection Molding Machines

Unusual noises often signal internal equipment problems:

Metal Debris in the Plasticizing Barrel

Solution: Stop the machine and clean it out.

Internal Failure of Plasticizing Motor, Bearing Damage, or Bearing Seat Wear

Solution: Repair or replace based on the specific situation.

Motor Section Failures

The motor is the power source of the drive system. Common problems include:

Bearing Damage or Excessive Clearance with End Cover

Solution: Replace the bearing or repair the end cover.

Loose Fixing Screws or Coupling Wear

Solution: Tighten the screws and replace the coupling.

Oil Pump Section Failures

Stable hydraulic system operation relies on proper oil pump function:

Oil Pump Blockage or Contaminated Oil

Solution: Clean the oil circuit and replace with clean hydraulic oil.

Spring Wear, Seal Aging, Wear on Stator/Rotor/Blades, or Bearing Damage

Solution: Repair or replace based on the extent of wear.

Regular Lubrication: Ensure all moving parts are well-lubricated.

Cleaning and Maintenance: Prevent foreign objects from entering the drive system.

Fastening Checks: Regularly inspect screws and nuts for looseness.

Oil Management: Use clean hydraulic oil and perform regular filtration or replacement.

Recording and Analysis: Maintain a failure log, analyze frequent issues, and develop preventive measures.