Hot runner systems are essential for efficient, high-quality injection molding—but they require regular maintenance to perform reliably. Over time, issues like contamination, wear, misalignment, or flash can arise, impacting part quality and production uptime.

Here’s a practical, step-by-step guide to handling some of the most common hot runner maintenance tasks without unnecessary downtime or mold disassembly.

Contamination—especially when using regrind material—is common and can clog gates, disrupt flow, and cause defects.

Best Practice:

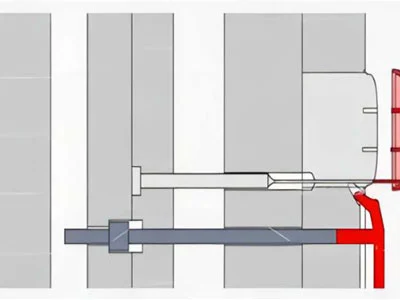

A well-designed hot runner system should allow gate cleaning without removing the hot half or the entire mold. Some systems enable the cavity plate to be pulled back from the core, fully exposing the hot runner nozzles and providing clear access to the back of the gates. This makes it easy to remove any accumulated residue directly in the press, minimizing downtime.

Heater failure can lead to inconsistent melt temperature and flow issues.

Best Practice:

Nozzle heater replacement should follow the same accessibility principle as gate cleaning. If your system allows easy exposure of the nozzles, swapping heaters becomes a quick in-machine task rather than a lengthy teardown job.

Wear or thermal expansion can cause leaks or misalignment in tapered sealing surfaces over time.

Best Practice:

In most cases, re-seating the taper by lapping it with its matching seat is sufficient. If needed, shims can be added to restore proper fit and seal. This maintains melt containment and prevents drool or stringing.

Flash occurs when plastic escapes into gaps between mold components—common during startup or machine malfunctions.

Best Practice:

Areas prone to flash (e.g., around ejector rings) must be easily accessible. Design your mold with sufficient clearance and operational travel so that bolts or components can be removed, cleaned, or adjusted without disassembling the entire tool.