Ever struggled to remove a plastic part from its mold, or noticed unsightly scratches on a finished product? The culprit is often an overlooked design detail: the draft angle. This seemingly simple feature is one of the most critical elements for achieving high-quality, manufacturable plastic parts.

What is a Draft Angle?

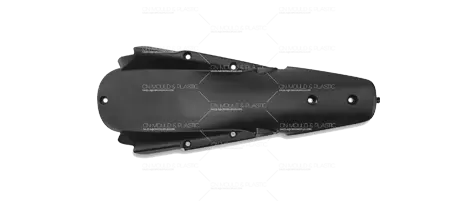

As a molded part cools, it shrinks. This causes it to tightly grip onto core features (like pins or inserts) or adhere to cavity walls. To facilitate easy ejection and prevent surface damage, we design a slight taper on the part's surfaces parallel to the mold opening direction. This taper is the draft angle.

Simply put, it's the angle applied to part walls to ensure they can be cleanly and efficiently removed from the mold without sticking or scratching.

Key Design Considerations

Designing an effective draft angle involves two primary factors:

1. Direction: The direction of the draft is determined by the mold's parting line. It must always allow the part to be released from the mold halves without getting caught.

2. Size: The required angle size isn't arbitrary; it depends on several factors:

Material: Rigid plastics (e.g., PS, PC) require larger angles than soft, flexible ones (e.g., TPE, TPU).

Geometry & Depth: Taller parts or deep holes need a smaller but sufficient angle to maintain dimensional integrity. More complex shapes or parts with many internal features also demand larger angles.

Wall Thickness: Thicker walls increase the shrinkage force gripping the core, necessitating a larger draft angle.

Surface Finish: Textured or rough surfaces create more friction and require a significantly larger angle than polished surfaces.

How to Apply Draft Angles

The application differs for internal and external features:

For Internal Features (Holes/Bosses): The base dimension is taken at the small end of the core pin. The material is added, making the feature larger as it moves away from the core.

For External Features (Walls/Ribs): The base dimension is taken at the large end of the cavity. The material is removed, making the feature smaller as it moves away from the cavity.

Draft Angles and Tolerances

A crucial rule to remember: A draft angle is typically not included in the part's tolerance range. It is an additional, necessary feature for manufacturability.

However, for high-precision parts, draft can sometimes conflict with tight dimensional requirements. In these cases, strategic design is key:

Place the parting line to minimize the visual or functional impact of the draft.

Reduce the height of the drafted wall where possible.

This helps minimize the deviation between the part's as-molded dimensions and its theoretical "perfect" geometry.

Practical Guidelines

Here are some common starting points for draft angles:

Height < 50 mm: 1/30 to 1/50 of the height

Height between 50-100 mm: 1/30 to 1/60

Height > 100 mm: 1/60

Generally, a more aggressive angle of 1/12 to 1/14 is required due to the increased surface area and friction.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk