Demolding is the final step in the injection molding cycle. Improper demolding can cause uneven force distribution and deformation of the product during ejection, leading to defects.

Two Main Demolding Methods:

There are two main types of demolding methods:

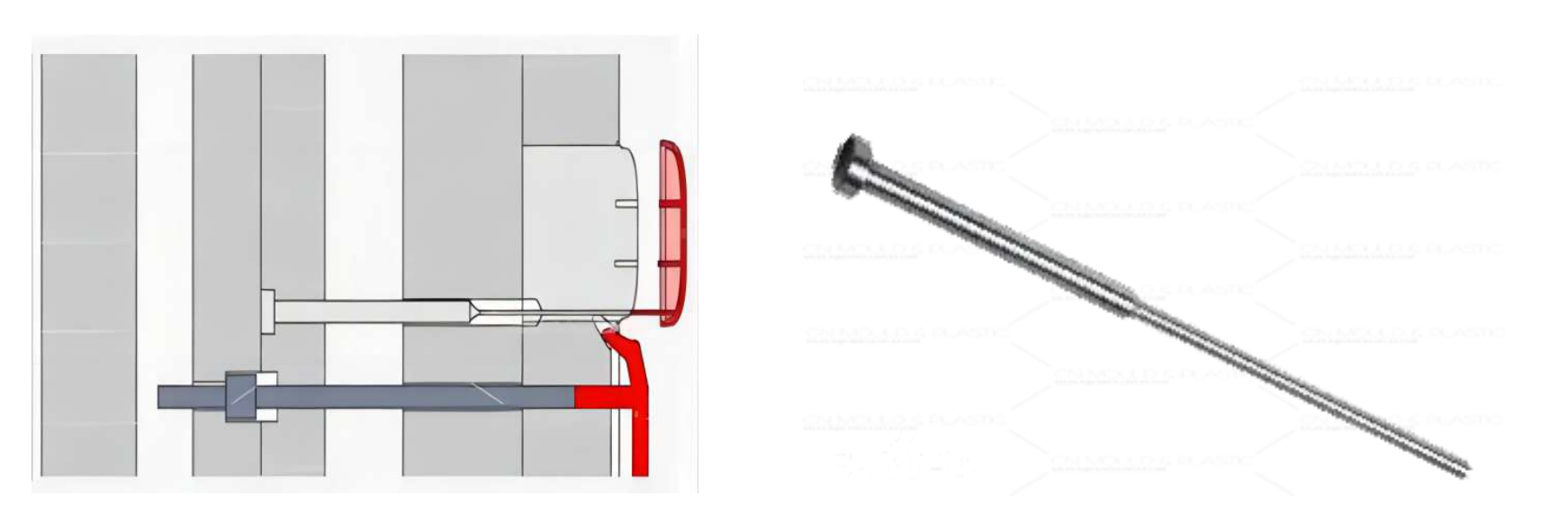

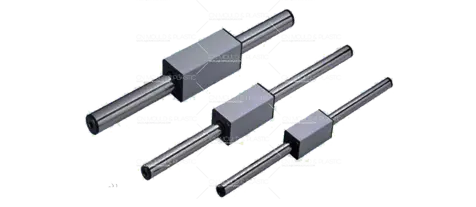

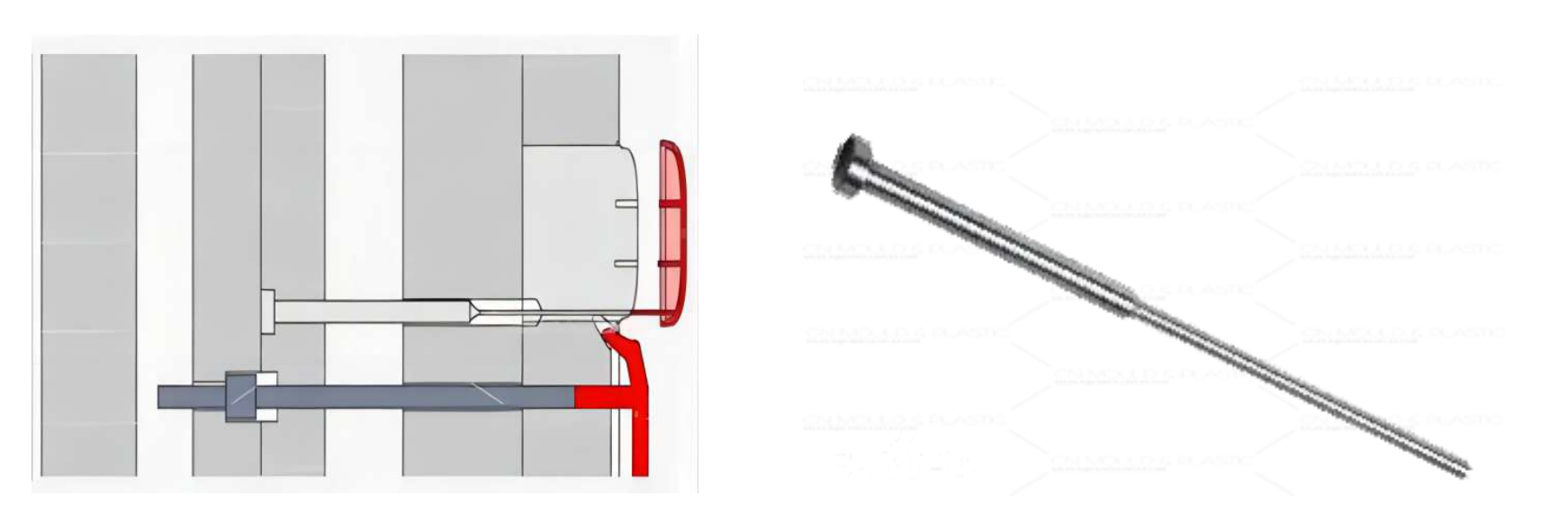

1. Ejector Pin Demolding: This method uses ejector pins to push the product out of the mold cavity. The pins should be evenly distributed and placed in areas with the highest demolding resistance and where the product has the highest strength and rigidity to prevent deformation or damage.

2. Stripper Plate Demolding: This method uses a stripper plate to move the product out of the mold cavity. It is commonly used for deep-cavity, thin-walled containers and transparent products where ejector pin marks are not allowed. The stripper plate provides a large and uniform demolding area with smooth movement, leaving no visible marks.

Choosing the Right Demolding Method:

The choice of demolding method depends on several factors, including:

1. Product geometry: Complex shapes may require a combination of ejector pins and a stripper plate.

2. Product material: Some materials, such as glass-filled nylon, are more prone to cracking during demolding and may require special care.

3. Wall thickness: Thinner walls may require a stripper plate to prevent deformation.

Designing for Demolding:

When designing a mold, it is important to consider the demolding process and incorporate features that will facilitate smooth and efficient demolding. Some key considerations include:

1.Draft: Adding draft to the mold walls allows the product to be easily released.

2.Parting line: The parting line should be located in a way that minimizes demolding resistance.

3.Ejector pin placement: Ejector pins should be placed in areas with the highest demolding resistance and where the product has the highest strength and rigidity.

4.Stripper plate design:The stripper plate should be designed to provide a large and uniform demolding area with smooth movement.

Conclusion:

Demolding is an important step in the injection molding process that can have a significant impact on the quality of the final product. By understanding the different demolding methods, selecting the right method for the product, and designing the mold for efficient demolding, manufacturers can ensure high-quality products and efficient production.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk