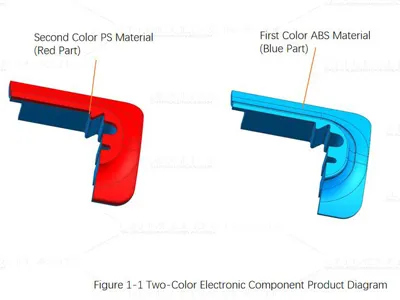

Water transfer printing technology is a kind of printing that uses water pressure to hydrolyze a polymer - based transfer paper/plastic film with a colored pattern. Water transfer printing is a transfer technology developed to address the complex shapes and blind spots that cannot be overcome by general traditional printing, hot stamping, pad printing, and screen printing.

I. Principle of Water Transfer Printing

After printing a colored pattern on a water - soluble polymer film, it is laid flat on the surface of a water tank. Using the principle of water pressure, the colored pattern is coated on the surface of the product. After cleaning and drying, a layer of transparent coating is sprayed.

II. Water Transfer Printing Process Flow

1. Film Activation

Lay the water - transfer film flat on the water surface of the transfer water tank with the graphic layer facing up. Keep the water in the tank clean and basically in a neutral state. Spray an activator evenly on the surface of the graphic layer to activate the graphic layer, making it easy to separate from the carrier film. The activator is an organic mixed solvent mainly composed of aromatic hydrocarbons, which can quickly dissolve and damage polyvinyl alcohol without damaging the graphic layer, leaving the graphic in a free state.

2. Water Transfer Printing Process

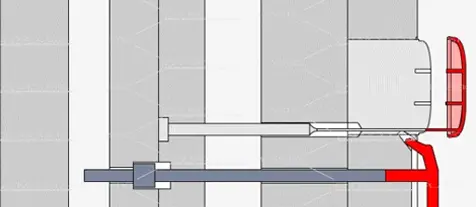

Gradually bring the item to be water - transfer - printed close to the water - transfer film along its contour. The graphic layer will slowly transfer to the surface of the product under the action of water pressure. Adhesion is generated due to the inherent adhesion between the ink layer and the printing material or special coating. During the transfer process, the fitting speed between the printing substrate and the water - transfer film should be kept uniform to avoid the film from wrinkling and making the graphic unappealing. In principle, appropriate stretching of the graphic should be ensured, and overlapping should be avoided as much as possible, especially at the joints. Excessive overlapping will give a messy appearance. The more complex the product, the higher the requirements for operation.

Water temperature is an important parameter affecting the transfer quality. If the water temperature is too low, the solubility of the base film may decrease; if the water temperature is too high, it is easy to damage the graphic and cause it to deform. The transfer water tank can be equipped with an automatic temperature - control device to keep the water temperature within a stable range. For a large number of workpieces with relatively simple and uniform shapes, special water - transfer - printing equipment can also be used instead of manual operation. For example, for cylindrical workpieces, they can be fixed on a rotating shaft and rotated on the film surface to achieve graphic layer transfer.

3. Drying and Transparent Paint Spraying Process

After natural drying, put it in an oven for further drying to improve the adhesion of the graphic. The drying temperature is 70°C for about 60 minutes. After natural drying, it needs to be treated with a transparent varnish spray and cured with a curing machine. When spraying the transparent varnish, it is necessary to prevent dust from falling on the surface, otherwise the appearance of the product will be greatly affected. The control of the coating thickness is achieved by adjusting the viscosity and spraying amount of the transparent varnish. Spraying too much is likely to reduce the uniformity.

III. Characteristics of Water Transfer Printing

(1) The water transfer printing process is suitable for the complex shapes and surfaces of any material [such as plastics (ABS, PC, PP), wood, metal, glass, bakelite, ceramics, etc.].

(2) The water transfer printing process has water - proof properties and does not fade easily, keeping the beautiful appearance unchanged for a long time.

(3) There are a large variety of water - transfer - printing patterns. It is also possible to design your own patterns and patterns.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk