Process Control: The Foundation of Quality

Improper machine settings are a primary culprit. Here’s what to check:

Insufficient Pressure & Time: Low injection pressure, short injection/holding times, or a slow injection rate fail to adequately pack material into the cavity, leading to shrinkage as the plastic cools.

Temperature Issues: Excessively high melt or mold temperatures, or insufficient part cooling before ejection, prevent the material from setting properly. Conversely, cold inserts can cause localized shrinkage around them.

Machine Issues: A nozzle that is too small or partially clogged causes significant pressure loss.

Solutions:

Increase packing force: Appropriately raise injection pressure and speed to compress the melt. Extend injection and holding times to compensate for shrinkage. Note: Avoid excessive holding pressure to prevent other defects like bumps.

Optimize cooling: Ensure the part cools sufficiently in the mold. Lower melt and mold coolant temperatures. For localized sinks, enhance cooling in that specific area while maintaining overall uniform cooling.

Targeted fixes: For sinks near the gate, extend holding time. For sinks in thick sections, increase in-mold cooling time. For sinks around inserts, pre-heat the inserts.

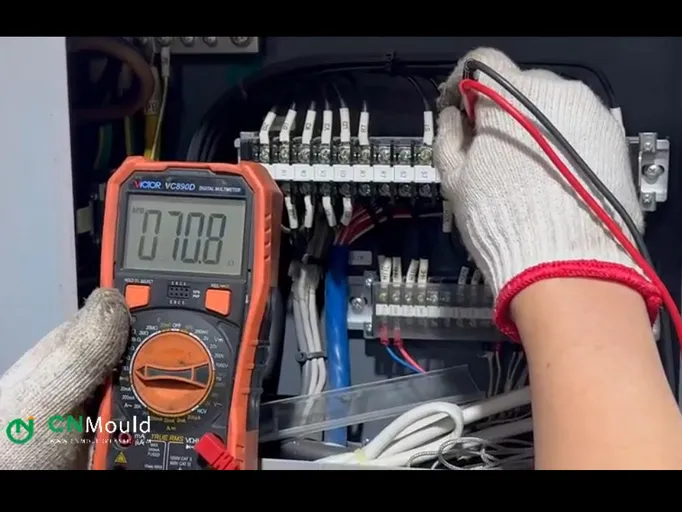

Maintain equipment: Clear nozzle blockages or replace the nozzle if necessary. Ensure the feed system provides adequate material.

Mold Design: Ensuring Smooth Flow

The mold itself can create obstacles that lead to sinks.

Restricted Flow: Gates and runners that are too small create high resistance. Poor venting traps air, hindering material flow and pressure transfer. Asymmetric gate placement causes unbalanced filling.

Wear and Tear: Worn-out mold components can lead to pressure release ("decompression").

Solutions:

Optimize flow channels: Enlarge gates and runner cross-sections. Place gates symmetrically and position them at the part's thickest section to facilitate packing.

Address remote sinks: If sinks appear far from the gate, it indicates a flow obstruction. Enlarge the runner system, especially at bottlenecks, and consider extending the runner closer to the problem area.

Use advanced gating: For thick-walled parts, a tab gate is highly effective. This method attaches a small tab (wing) to the part, with the gate placed on the tab. This transfers the sink defect to the tab, which is later trimmed off, leaving a clean part.

Perform regular maintenance: Check and replace worn components. Improve venting to allow trapped air and gases to escape.

Material Matters: Choosing the Right Resin

The properties of the plastic material directly impact shrinkage.

High Shrinkage Rate: Some resins naturally shrink more than others.

Poor Flowability: Material with low viscosity may not fill and pack the cavity effectively.

Contamination: Insufficient internal lubricant or the presence of moisture can exacerbate the issue.

Solutions:

Select low-shrinkage resins: For high-surface-quality parts, prioritize resin grades with a lower shrinkage rate.

Improve flow: Add a small amount of lubricant to improve melt flow or compensate by further enlarging the gate/runner system.

Dry the material: Always pre-dry hygroscopic resins (like nylon, PET) according to the manufacturer's specifications to prevent moisture-related defects.

Part Design: The Blueprint for Success

The part's geometry is often the starting point. Non-uniform wall thickness is a classic cause of sinks.

Thick Sections: Thick areas cool slower than thin ones. Without sufficient continued pressure from the holding phase, the outer skin solidifies while the inner material shrinks, pulling the surface inward.

Solutions:

Design for uniform thickness: This is the golden rule. Aim for consistent wall thickness throughout the part design.

Manage transitions: When thickness variations are unavoidable, design gradual transitions. Then, compensate by adjusting the molding process—specifically by placing the gate strategically at the thickest section and optimizing the gate size and holding pressure to pack out that area effectively.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk