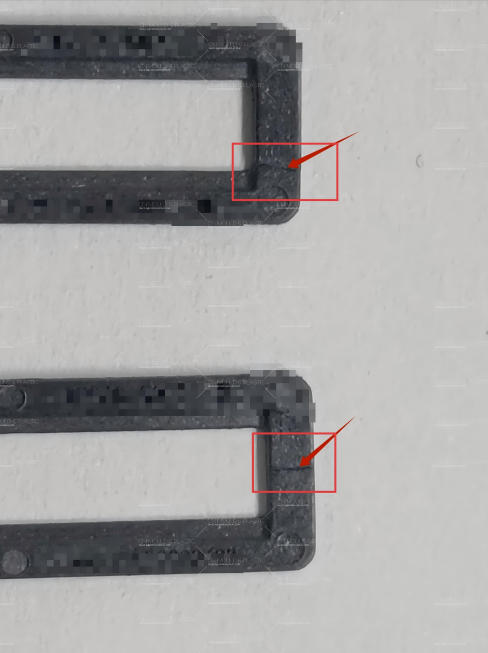

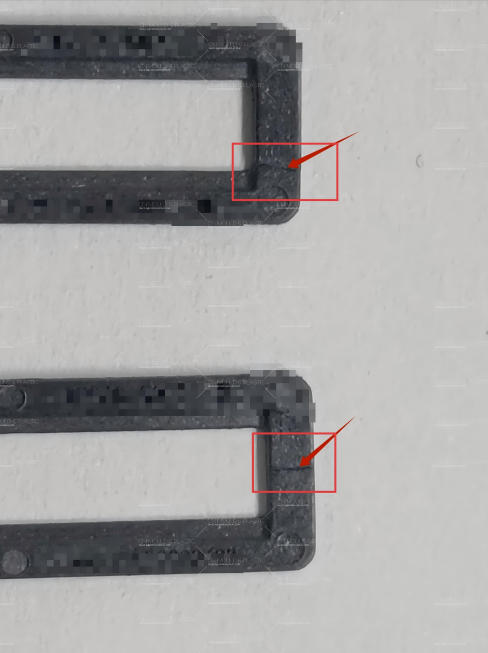

The main causes of weld lines are: When molten plastic encounters inserts, holes, areas with discontinuous flow velocity, or interruptions in the mold filling flow within the cavity, multiple streams of melt converge. Additionally, if gate jetting occurs during filling, the material may not fully fuse.

Material Temperature Too Low

Low-temperature melt has poor flow convergence performance, making it prone to forming weld lines. If weld lines are poor due to low material temperature, the melt temperature can be appropriately increased. Often, insufficient material temperature is the issue, so raising the melt temperature is recommended. At the same time, the flow of cooling water in the mold should be controlled, and the mold temperature should be appropriately increased.

Generally, the strength at weld lines in plastic parts is relatively weak. If localized heating is applied to the corresponding area of the mold where weld lines occur, raising the local temperature of the weld line area, the strength at the weld line can often be improved.

If low-temperature molding is necessary due to special requirements, the injection speed or injection pressure can be appropriately increased to enhance the melt convergence performance. A small amount of lubricant can also be added to the raw material to improve flow properties.

Mold Defects

The structural parameters of the mold’s gating system significantly affect the weld line condition, as poor weld lines mainly occur at the convergence points of melt flow. Therefore, gate designs with fewer flow divisions should be adopted, and gate positions should be rationally selected to avoid interruptions in the filling flow. Where possible, pinpoint gates are preferred because they do not create multiple flow streams, preventing melt convergence from two directions and making weld lines easier to avoid.

If there are too many or too large gates in the mold’s gating system, improper gate positioning, excessive distance from the gate to the weld line location, or overly large gate cross-sections causing high flow resistance, poor weld lines can occur, resulting in visible weld lines on the plastic part surface. In such cases, the number of gates should be minimized, gate positions optimized, gate cross-sections enlarged, auxiliary runners added, and the diameters of the sprue and runners expanded.

To prevent low-temperature melt from entering the cavity and causing weld lines, a cold slug well should be incorporated into the mold while raising the mold temperature.

Additionally, weld line areas often experience flash due to high-pressure filling. However, once flash occurs, weld lines typically do not produce sink marks. Therefore, such flash is often not treated as a defect. Instead, a small groove is created in the mold at the flash location to transfer the weld line to an additional flash area. The flash is then removed after molding, which is a common method for addressing weld line issues.

Poor Mold Venting

When the melt flow line coincides with the mold parting line or insert seams, air trapped by multiple melt streams in the cavity can escape through the parting line gaps or insert seams. However, when the melt flow line does not align with the parting line or insert seams, and venting holes are improperly placed, trapped air cannot escape. Bubbles are compressed under high pressure, gradually shrinking until they become tiny points. The kinetic energy of the compressed air converts to heat under high pressure, raising the temperature at the melt convergence point. If this temperature far exceeds the decomposition temperature of the material, yellow spots appear at the weld line; if it exceeds the decomposition temperature, black spots form.

Generally, such spots near weld lines on plastic parts are regularly distributed at the melt convergence points. During operation, these should not be mistaken for impurity spots. The main cause of such spots is poor mold venting, resulting in carbonization points formed by high-temperature decomposition of the melt.

When this issue occurs, first check whether the mold venting holes are blocked by solidified material or other debris, and whether there are obstructions at the gate. If carbonization spots persist after clearing blockages, additional venting holes should be added at the melt convergence points in the mold. Alternatively, gate repositioning, appropriately reducing clamping force, or increasing venting gaps can accelerate melt convergence. In terms of process adjustments, measures such as lowering material and mold temperatures, shortening injection time, and reducing injection pressure can also be taken.

Improper Use of Release Agents

Excessive use of release agents or selecting the wrong type can cause weld lines on plastic parts. In injection molding, release agents should generally be applied sparingly and evenly only to hard-to-release areas such as threads. In principle, the use of release agents should be minimized.

The selection of release agents must consider molding conditions, plastic part geometry, and material type. For example, pure zinc stearate can be used for various plastics except polyamides and transparent plastics, but when mixed with oil, it becomes suitable for polyamides and glass-filled plastics. Similarly, silicone oil-toluene solutions can be used for various plastics and remain effective for extended periods after application, though they require heating and drying after brushing, making the process more complex.

Unreasonable Plastic Part Design

Excessively thin or uneven wall thickness, or too many inserts, can lead to poor weld lines. In thin-walled parts, rapid melt solidification can easily cause defects, and melt flow tends to converge at thin sections, forming weld lines. Once weld lines occur in thin areas, the strength of the plastic part is compromised, affecting performance. Therefore, when designing plastic part geometry, ensure that the thinnest sections are thicker than the minimum allowable wall thickness for molding. Additionally, wall thickness should be as uniform as possible, and the use of inserts should be minimized.

Moreover, reduce or avoid using materials with high volatile content. Unclean mold surfaces with oil residue, excessive moisture or volatile content in the raw material, and improper cavity temperatures can also cause bubbles in molded parts.

Other Causes

Moisture in the raw material, poor distribution of fiber fillers in the melt, overly rapid melt solidification, and significant variations in wall thickness can all lead to weld lines on plastic part surfaces.

If the melt temperature is too low, the nozzle orifice is too small, pressure loss in the injection machine barrel is excessive, or the injection plasticizing capacity is insufficient, measures such as drying the raw material, regularly cleaning the barrel, appropriately increasing barrel temperature, using a larger nozzle orifice, improving mold structure, controlling cooling water flow, and increasing insert temperature should be taken based on the specific situation.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk