When calculating the labor cost for manufacturing a specific product, several aspects of the workload must be taken into account. These factors not only influence overall efficiency but also impact product pricing and competitiveness. Below, we break down the key areas where labor plays a role in injection molding processes.

Transporting Raw Materials to the Machine

Many modern molding plants use automated piping systems to transport materials from silos directly to the machine hopper, often incorporating colorants or regrind as needed. However, if manual handling—such as using carts—is required, these costs are typically absorbed into general overhead rather than assigned directly to a specific product.

Handling Scrap: Transport, Sorting, and Storage

The labor involved in managing waste—sorting, moving, and storing scrap—is also generally considered part of factory overhead rather than a direct product cost.

Machine Operation and Manual Interventions

The actual labor of operating the mold and machine depends largely on the level of automation. Most molds today are designed to run without an operator present. However, poorly designed or manufactured molds may require manual part removal, flash and runner trimming, or positioning parts to prevent deformation after ejection. These tasks add direct labor to the production process.

Insert Molding

When inserts are needed, they are often placed manually during each cycle. Even with automated molding, an operator may still be required for this step. For high-volume production, robotic systems can automate insert placement—a worthwhile investment despite higher equipment costs, as it boosts productivity, reduces labor, improves quality, and enhances safety by removing personnel from the machine area.

Product Handling and Transportation

Moving finished parts to subsequent processes, storage, or shipping can be highly automated for large production runs, significantly reducing labor. For smaller batches or varied product sizes and shapes, manual handling may still dominate. While a detailed discussion is beyond this post, it’s important to recognize that handling costs can be substantial.

Post-Processing Operations

Activities such as stacking, sorting, labeling, assembly, finishing, and packaging often involve considerable manual labor. Automation is feasible for high-volume production, but even in low-volume scenarios, mechanized solutions are increasingly economical, minimizing manual input.

Mold Setup and Changeover

This includes installing the mold, optimizing machine settings, and removing the mold after a production run. Frequent changeovers (every few hours, days, or weeks) make setup a significant expense. For long production runs, setup costs may be negligible.

Note: After each adjustment to temperature, pressure, or cycle time, a stabilization period is needed before consistent production resumes. For multi-cavity molds, each cavity should be checked after adjustments. Ideally, molds should be pre-tested by the manufacturer to establish optimal processing conditions—saving time, material, and energy during customer trials.

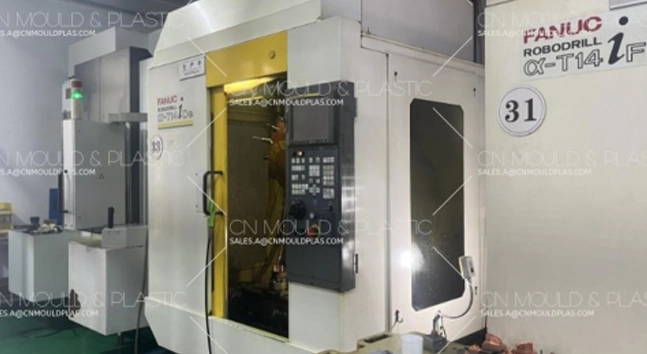

Efficiency in Setup and Changeover

For operations with frequent mold changes, reducing setup time is critical. Standardizing procedures, simplifying connections (water, electricity, air), and ultimately automating mold changes can cut downtime significantly. For mid-sized molds (~500 kg), changeover times have been reduced to 0.5–4 hours. Pre-heating hot runner systems before installation is one key time-saving strategy.

Although setup costs are often treated as overhead, for short, frequent production runs they should be allocated directly to the product cost.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk