In injection molding, sticking and poor part ejection are common but frustrating issues. While multiple factors can contribute, mold-related problems are often the primary cause. Understanding these causes and implementing the right fixes is key to smooth, efficient production.

Here’s a breakdown of common mold faults and how to address them:

1. Rough Cavity Surface

Scratches, dents, tool marks, or oil residue inside the cavity or runners can cause plastic to adhere, making ejection difficult.

✅ Solution: Polish the cavity and runners to a smooth finish—preferably in the direction of material flow. Consider applying a hard chrome plating to reduce surface friction and improve release.

2. Mold Wear or Excessive Gaps in Inserts

If flash forms in worn areas or gaps between mold inserts, it can lock the part in place.

✅ Solution: Repair damaged sections and minimize insert gaps to prevent flash formation.

3. Insufficient Mold Rigidity

A mold that deforms under injection pressure may not open easily or may be permanently damaged. Excessive deformation can even lead to cracking.

✅ Solution:

During trial runs, use dial indicators to monitor cavity and mold frame deflection.

Start with lower injection pressure and increase gradually while watching deformation.

If clamping fails due to excessive rebound, disassemble the mold and remove the part after softening it with heat.

For added strength, reinforce the mold with an external frame.

4. Inadequate Draft Angle or Poor Parallelism Between Mold Halves

Insufficient draft makes ejection hard, often causing warping, whitening, or cracking at ejection points. Misaligned moving and fixed plates can shift the cavity.

✅ Solution: Ensure proper draft angles are designed in, and verify that mold plates are parallel.

5. Poor Runner System Design

Problems include runners that are too long or narrow, weak junctions between main and sub-runners, lack of a cold slug well, unbalanced gates, or mismatches between sprue bushing and nozzle.

✅ Solution:

Shorten runners and increase their cross-sectional area.

Strengthen connections between main and branch runners.

Add a cold slug well at the sprue.

Use auxiliary gates to balance fill rates in multi-cavity molds.

Ensure the sprue’s small-end diameter is 0.5–1 mm larger than the nozzle orifice, and that the sprue bushing radius is 1–2 mm larger than the nozzle radius.

6. Improper Ejection System Design or Operation

Short stroke, uneven ejection, or poor ejector plate movement can all hinder part release.

✅ Solution:

Maximize effective ejector pin area and ensure adequate stroke.

Optimize ejection speed—not too fast or too slow.

Keep sliding components clean and well-lubricated.

Check parallelism of ejector pins and guide pins, and avoid bent components.

For large molds, use multiple ejector pins to ensure balanced force distribution.

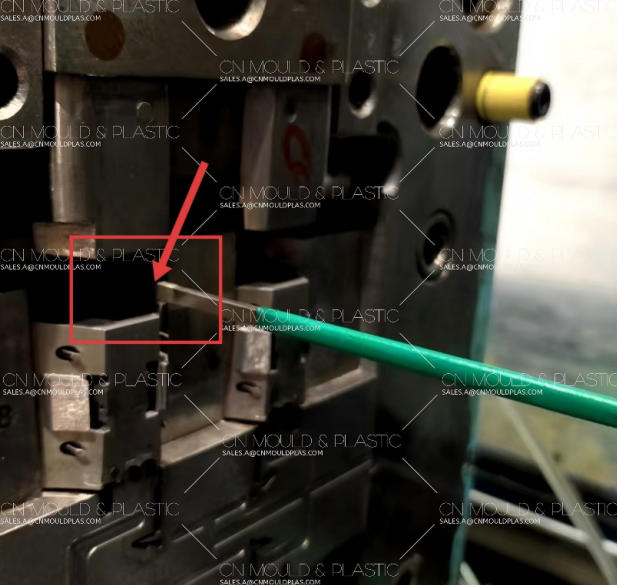

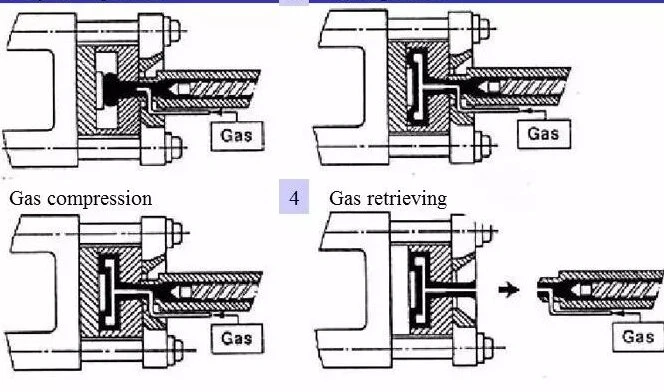

7. Poor Venting or Lack of Air Vents in Cores

Trapped air can create suction, preventing clean ejection.

✅ Solution: Improve venting channels and add air vents in core areas to allow air escape.

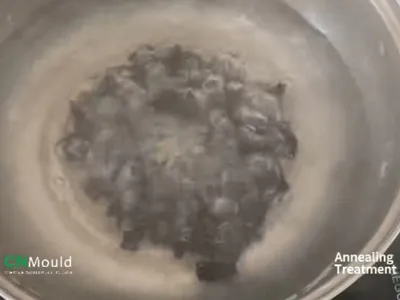

8. Incorrect Mold Temperature or Cooling Time

If sticking occurs at the parting line, try raising mold temperature or shortening cooling time.

If sticking is inside the cavity, lower temperature or extend cooling.

Overheated fixed half molds can also cause issues.

Porous or soft cavity materials may increase sticking—consider switching to hardened steel or surface plating.

9. Other Mold Defects

Low gate temperature, absence of a gate puller, recesses below the parting line, or misalignment at the parting surface can all contribute.

✅ Solution: Review mold design for these issues and make corrections where needed.