Injection molding is a precise and efficient manufacturing process, but it’s not without its challenges. One frequent issue is the short shot—when the molded part isn’t completely filled, resulting in an incomplete or “unfilled” product. This defect can lead to wasted materials, production delays, and quality failures.

Short shots occur when molten plastic fails to reach all areas of the mold cavity before solidifying. Let’s explore the key reasons behind this defect and practical steps to resolve it.

1. Material Feeding & Preparation Issues

Cause: Material “bridging” in the hopper, leading to insufficient feed.

Solution: Check and clear the hopper; ensure consistent material flow.

Cause: Insufficient plasticization or low residual material in the barrel.

Solution: Adjust screw speed and back pressure; optimize shot size.

Cause: Plastic contains moisture, excess volatiles, or trapped air.

Solution: Pre-dry the material; ensure proper material mixing and degassing.

2. Machine & Process Settings

Cause: Low injection pressure or speed.

Solution: Increase injection pressure and speed settings.

Cause: Injection time or holding time too short.

Solution: Extend injection and holding times appropriately.

Cause: Low barrel or nozzle temperature; nozzle diameter too small.

Solution: Raise temperature settings; use a larger nozzle if needed.

Cause: Plastic has poor flowability, leading to excessive flash.

Solution: Adjust temperature to improve flow without causing overflow.

3. Mold Design & Condition

Cause: Runners or gates are too small.

Solution: Increase runner size or enlarge gate dimensions.

Cause: Unbalanced filling in multi-cavity molds.

Solution: Adjust gate layout or runner system to balance flow.

Cause: High flow resistance in the mold; poor gate location or design.

Solution: Optimize gate position, shape, and runner layout.

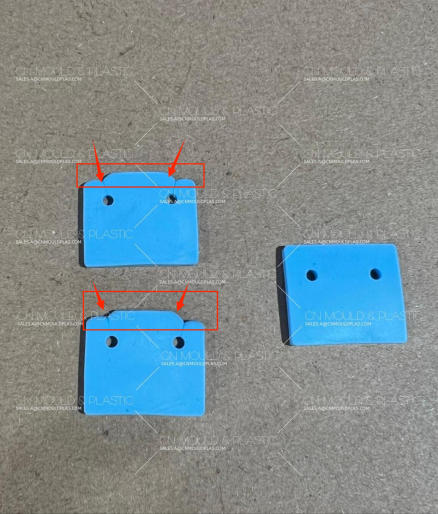

Cause: Inadequate venting, trapping air inside the mold.

Solution: Add or enlarge vents to allow air to escape.

Cause: Mold temperature too low; plastic cools too quickly.

Solution: Increase mold temperature and adjust cooling time.

Cause: Excessive use of release agent or moisture in the cavity.

Solution: Use release agent sparingly; ensure mold surfaces are dry.

4. Part Design & Feasibility

Cause: Part walls are too thin, or geometry is too complex and large.

Solution: Where possible, simplify design or increase wall thickness.

Cause: Shot volume required exceeds machine capacity.

Solution: Use a larger injection machine or reduce number of cavities.