In the world of plastic injection molding, few quality issues are as frustrating and damaging as product cracking. This defect not only ruins the appearance of a part but, more critically, compromises its structural integrity and long-term reliability. Solving it requires moving beyond guesswork and adopting a systematic, root-cause-based approach. Based on an internal technical framework, this blog post breaks down the complex causes of cracking and outlines actionable solutions.

Cracking is rarely a simple, isolated problem. It is typically the result of an interplay between material properties, mold design, process settings, and post-processing.

1. Material Issues

Contamination & Moisture: The presence of contaminants, insufficient drying of resin, or excessive volatile content creates weak points in the material matrix.

Regrind Ratio: An excessively high percentage of recycled material can lead to inconsistent plasticization, uneven filler distribution, and non-uniform shrinkage, building in internal stress.

2. Mold Design Flaws

Poor Demolding Design: Thin walls, insufficient draft angles, and sharp corners or notches act as stress concentrators. When the part ejects or cools, these areas are prone to cracking.

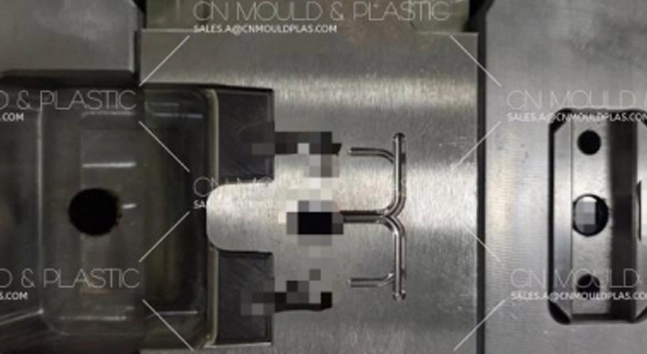

3. Ejection System & Stress

Improper Ejector Setup: Incorrectly positioned or malfunctioning ejector pins/rings can create high localized stress during part removal.

Excessive Ejection Force: Improper process conditions can make the part adhere strongly to the mold, requiring excessive force for ejection, which may crack the part.

4. Incorrect Process Parameters

Temperature: A mold temperature that is too low or uneven causes the plastic to cool too rapidly, locking in high residual stresses.

Pressure & Speed: Insufficient injection pressure or too slow an injection speed fails to properly pack and consolidate the melt in the cavity.

Time: Short injection or holding times lead to under-packing and shrinkage voids. Incorrect cooling times (either too long or too short) disrupt proper crystallization and stress relief.

5. Post-Processing Problems

Non-Uniform Cooling: Uneven cooling after demolding causes differential shrinkage.

Improper Use of Release Agent: Incorrect application can interfere with uniform part release and subsequent cooling.

For every root cause, there is a corresponding corrective action. A systematic troubleshooting sequence is key.

1. Start with the Material

Inspect and Prepare: Verify resin is free from contamination and is thoroughly dried according to the material supplier's specifications.

Control Regrind: Strictly manage the ratio of recycled to virgin material to ensure consistent melt flow and properties.

2. Optimize the Mold Design (Long-term Fix)

Redesign Critical Areas: Increase draft angles, eliminate sharp corners by adding radii, and review wall thickness uniformity to minimize stress concentration.

3. Calibrate the Ejection System

Adjust Ejectors: Ensure ejector pins/rings are correctly aligned, functional, and provide balanced ejection force.

Polish Mold Surfaces: A high-quality polish on cores and cavities can significantly reduce ejection resistance.

4. Fine-Tune the Process Parameters

Increase Mold Temperature: Raise and stabilize the mold temperature to promote slower, more uniform cooling and reduce residual stress.

Boost Pressure and Speed: Increase injection pressure and speed to ensure complete cavity filling and effective packing.

Optimize Timing: Extend injection and holding times to compensate for material shrinkage. Precisely set cooling time based on part geometry and material.

5. Standardize Post-Processing

Use Release Agent Judiciously: Apply a minimal, even coat of a suitable release agent only when necessary.

Control Post-Demolding Environment: Allow parts to cool in a consistent, draft-free environment if needed.