The cooperation between mold manufacturing enterprises and users is carried out in the form of "contracts". The main contents of the contract include three aspects: ① The accuracy, quality, and service performance of the mold; ② The mold production cycle, that is, the mold delivery period; ③ The price of the mold. These three aspects are actually the basic contents of the technical and economic requirements for mold design and manufacturing.

1. The Concept of "Accuracy" in Mold Manufacturing

To meet users' requirements for accuracy, quality, and service performance, the concept of "accuracy" must be established throughout the mold design and manufacturing process, and it should involve all personnel. This is of great importance, and the reasons are as follows:

1). Molds are precision forming tools and must meet the dimensional and shape accuracy requirements of workpieces (stamped parts, plastic parts, die - cast parts, forged parts, etc.). They must ensure the interchangeability of workpieces during mass - forming processing and meet the reliability requirements during long - term use (within the allowable service life range). Therefore, the accuracy level of molds usually needs to be at least 2 levels higher than that of the workpieces.

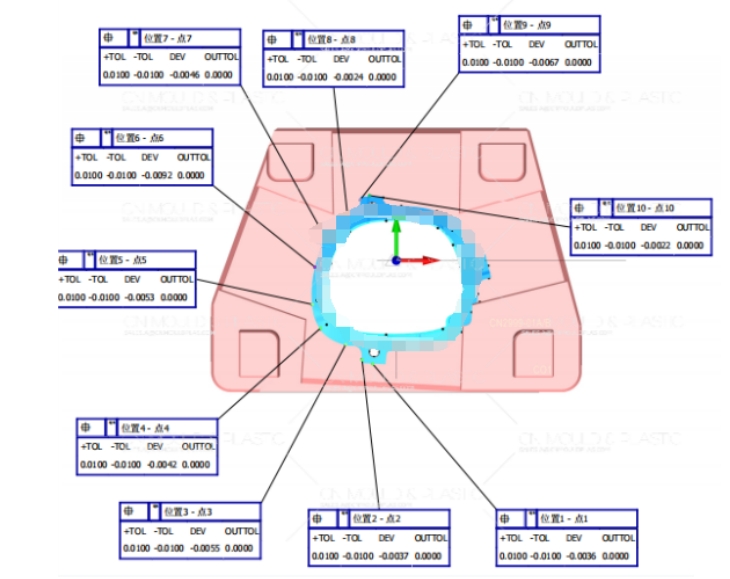

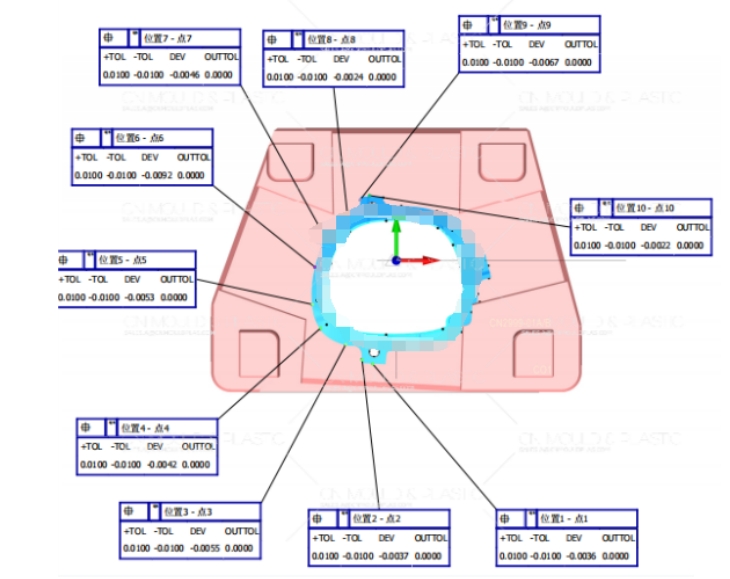

2). The accuracy of molds is also affected by the fit clearance and its uniformity between the forming parts (such as punches and dies). Thus, the fit accuracy between the guiding components, structural components, and supporting components of the mold, as well as the positioning and location accuracy between the connected parts, need to be further improved. In other words, to ensure the fit clearance and its uniformity between the forming parts, the accuracy and surface quality of each component that makes up the mold will be involved.

To ensure the accuracy requirements of this closed loop, it is necessary to improve the accuracy and quality of the components and parts.

2. Molds are Special - Purpose Products for Single - Piece Production

This requires strict quality management in terms of process technology, operation, and service. Therefore, during the production process, it is necessary to ensure that every quality link and quality factor are always under control, and the mindset and service concept of "quality first, user first" should be consistently implemented.

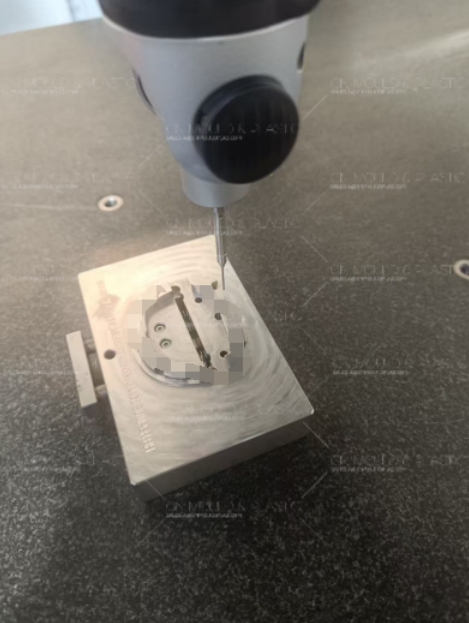

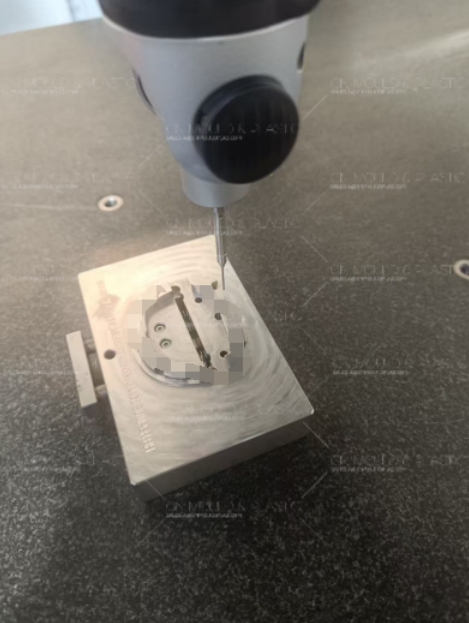

In the production of industrial products, the purpose of using molds is to ensure product quality, improve productivity, and reduce costs. To this end, in addition to correct mold design and the adoption of a reasonable mold structure (e.g., for micro insert molding dies), advanced mold manufacturing technology must also be guaranteed. When manufacturing molds, regardless of the method used, the following basic requirements should be met:

(1) High manufacturing accuracy: To produce qualified products and give full play to the effectiveness of the mold, the designed and manufactured mold should have a high level of accuracy. The accuracy of the mold is mainly determined by the accuracy of the products and the requirements of the mold structure. To ensure the accuracy of the products, the accuracy of the working parts of the mold is usually 2 - 4 levels higher than that of the products. The mold structure has high requirements for the fit between the upper and lower molds. Therefore, all components and parts that make up the mold must have a sufficiently high manufacturing accuracy. Otherwise, it is impossible to produce qualified products, and the mold may even be damaged.

(2) Short manufacturing cycle: The length of the mold manufacturing cycle mainly depends on the mold - making technology and the level of production management. In order to meet the production needs and improve the competitiveness of products, it is necessary to shorten the mold manufacturing cycle as much as possible on the premise of ensuring quality.

(3) Long service life: Molds are relatively expensive process equipment. Currently, the manufacturing cost of molds accounts for about 10% - 30% of the product cost. The length of their service life will directly affect the cost of the products. Therefore, except for special cases such as small - batch production and new product trial - production, molds are generally required to have a long service life. In the case of mass production, the service life of the mold is even more important.

(4) Low mold cost: The cost of the mold is related to the complexity of the mold structure, the mold material, the requirements for manufacturing accuracy, and the processing method. Mold technicians must rationally design and develop the processing technology according to the product requirements.

It must be pointed out that the above four indicators are interrelated and mutually influential. One - sided pursuit of mold accuracy and service life will inevitably lead to an increase in manufacturing costs. Of course, it is also not advisable to only focus on reducing costs and shortening the manufacturing cycle while ignoring the accuracy and service life of the mold. When designing and manufacturing molds, a comprehensive consideration should be made according to the actual situation. That is, on the premise of ensuring product quality, the mold structure and manufacturing method that are suitable for the product production volume should be selected to minimize the mold cost.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk