1. Mold Production Process

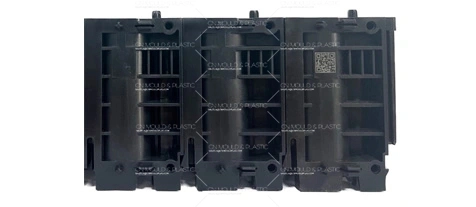

The mold production process refers to the entire process of transforming product information, technical specifications of parts, and price information provided by users into a mold through structural and process analysis. Based on this design, raw materials are then processed, assembled, and tested to become a functional forming tool.

The mold production process is divided into the following seven stages:

Overall Conceptualization:

Based on the content of the mold contract and relevant information.

Product Analysis:

Analyze the part structure, dimensional accuracy, surface quality requirements, and forming process of the product.

Structural Design:

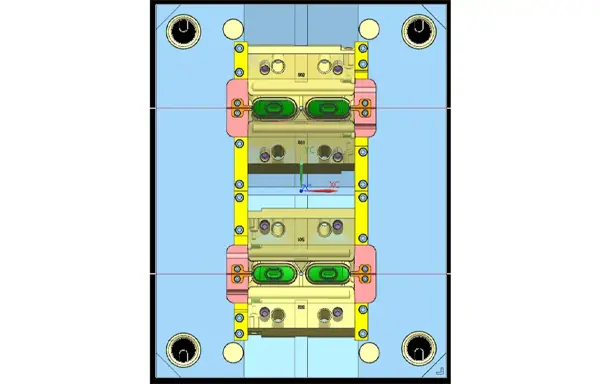

Create the model and design the structure of the forming components according to mold structural technology; conduct systematic structure design (including positioning, guiding, ejection systems, and parameter design), which is the assembly design.

1. Material Preparation and Process Planning: Prepare blanks for forming components and modules, source standard parts externally, compile NC/CNC machining programs based on the model design, and select cutting tools, fixtures, and measuring instruments.

2. Forming and Heat Treatment: Perform forming and hole machining using NC/CNC programs or traditional processes such as EDM and form grinding, followed by appropriate heat treatment.

3. Assembly and Testing: Assemble the mold according to the assembly process, conduct trial runs, make necessary repairs, and adjustments.

4. Inspection and Acceptance: Inspect the trial-manufactured parts (stamped parts, plastic parts, etc.) and the mold's performance and working parameters against technical standards and contract specifications before acceptance.

From the above process, it can be seen that standard parts of molds are generally purchased from the market. Mold manufacturers mainly process non-standard parts to meet design requirements and assemble them with standard parts into finished molds. This entire process defines the mold production process. For small and medium-sized molds (such as micro insert molding), which are the most widely used, standard parts account for a significant proportion. Therefore, modernizing the mold production process requires prioritizing mold standardization and establishing a comprehensive production and supply system for mold standards, which is the foundation for the modernization of the mold industry.

2. Mold Manufacturing Process

The mold manufacturing process is the key part of the mold production process, spanning six stages from production preparation to pre-acceptance testing. Before the assembly and trial stages, it consists of two parallel processes: the manufacturing of forming components and the procurement of standard and general parts. This process is a continuation of the mold design, aiming to transform design drawings into a functional mold. Therefore, correctly determining the process content, nature, and methods—especially the process combination for machining the forming surfaces—is crucial for optimizing the manufacturing process to achieve high precision, efficiency, and economic viability.

Composition of Mold Part Machining Processes

Mold parts are mainly classified into two categories: standard/general parts and forming components.

Standard and general parts include:

1. Plate Parts: Such as base plates, support plates, backing plates, and punch/die fixing plates, typically made of medium carbon steel or cast iron.

2. Cylindrical Parts: Including guide pillars, ejector pins, return pins, and locating pin,usually made of carbon steel or alloy steel.

3. Sleeve Parts: Such as guide bushes, positioning ring,and punch protection sleeves, commonly made of carbon steel.

Forming components mainly refer to punches, cores, dies, or cavities. Die blocks for stamping dies often adopt a segmented structure. Their blanks can be forgings, castings, or round steel, made from alloy tool steels, carbon tool steels, medium carbon steels, or alloy cast irons. These parts are essentially mechanical components, but their forming surfaces are often complex, requiring specialized forming processes.

Manufacturing Processes for Forming Components

1. Processes and Types of Machining

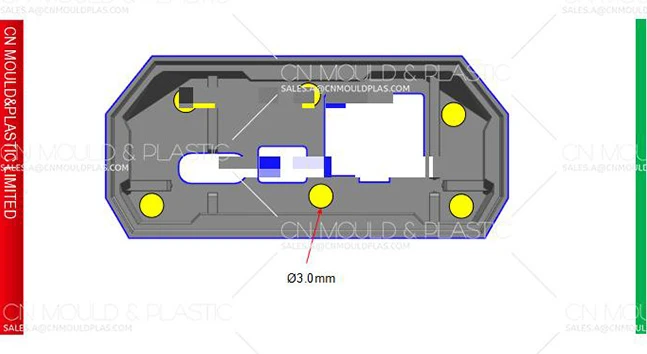

Modern mold manufacturing processes have been significantly streamlined. Standard mold parts can be sourced from the market with guaranteed precision and quality, and blanks for forming components, such as forgings and rolled plates, are also commercially available. Therefore, the main processes in mold manufacturing are the production of forming components and mold assembly. The manufacturing sequence for forming components is as follows:

1. Forming and Machining: Including hole machining, groove and plane processing.

2. Heat Treatment: Such as quenching, nitriding, and surface hardening.

3. Surface Finishing: Including texture processing, polishing, and grinding of plastic mold cavities.

Key machining processes for forming surfaces include:

• CNC Form Milling: The primary method for processing injection molds and die-casting molds, especially with the application of high-speed milling and 4-5 axis 联动加工.

• EDM Forming: Used for cavity machining of moderate precision molds and finishing after milling to reduce surface roughness.

• CNC Precision Coordinate Hole Machining.

• CNC WEDM: Used for final processing of stamping die components or pre-machining of high-precision molds.

• Precision Form Grinding: Mainly for precision machining of stamping die punches and die inserts.

• Extrusion Forming: For simple and shallow cavities.

• Precision Casting: Used for medium to large dies like automotive stamping dies.

2. Machining Operations for Mold Forming Components

The manufacturing process for mold forming components includes:

• Forming Surface Machining: Shaping of complex surfaces through various processes.

• Hole Machining: Drilling and finishing of holes.

• Heat Treatment: Processes like quenching, nitriding, or surface treatments to enhance material properties.

• Surface Finishing: Polishing, grinding, and texture processing to meet surface quality requirements.

With the widespread adoption of CNC machining, there is a trend toward process concentration, where multiple operations or processes can be completed in a single setup. However, each machining surface still typically undergoes roughing, semi-finishing, and finishing operations to ensure dimensional accuracy and surface quality.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk