Product Description

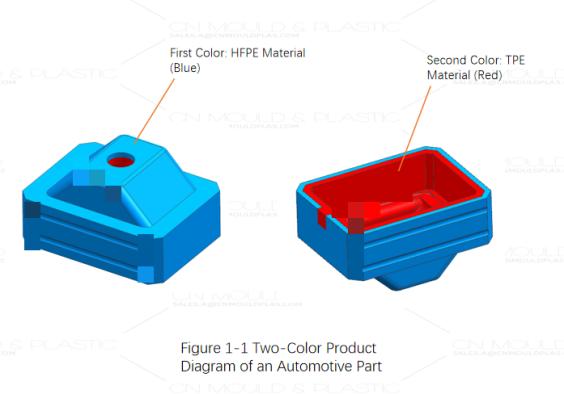

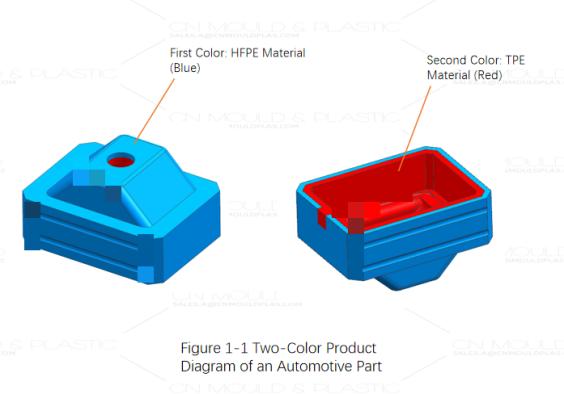

Figure 1-1 shows a two-color product drawing of an automotive part. The outer green layer is made of HDPE compound (hard plastic), and the inner orange layer is made of TPE compound (soft plastic).

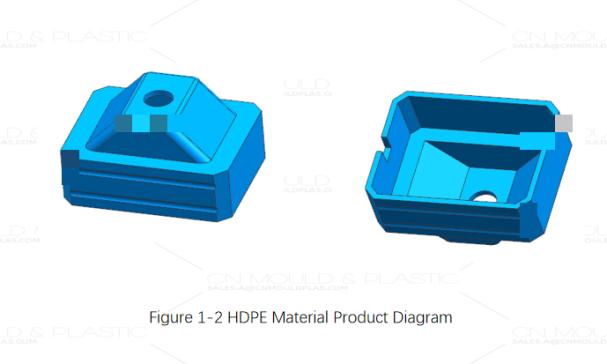

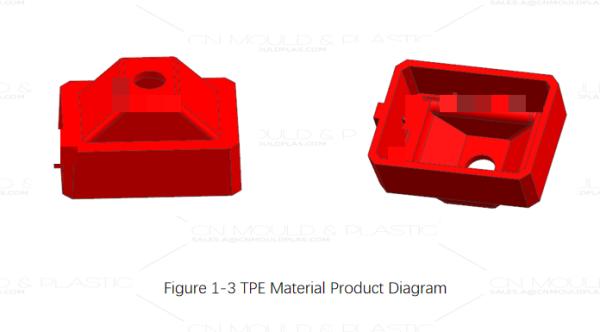

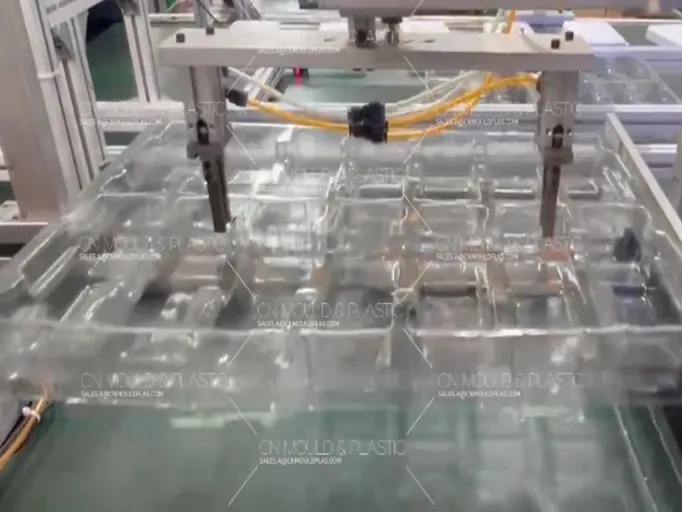

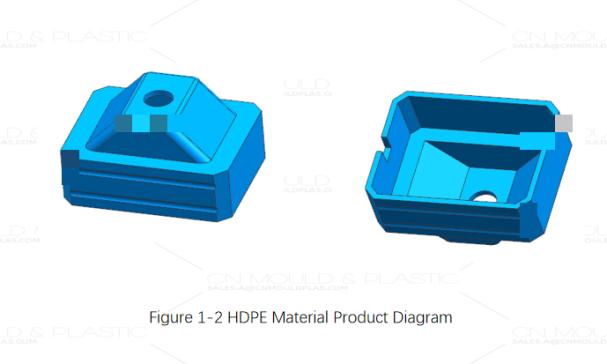

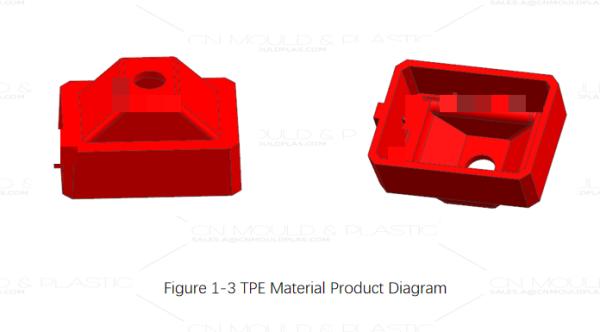

Figure 1-2 shows the outer HDPE compound product drawing. Its average wall thickness is 1.6 mm, overall dimensions are 8.3 mm × 11.4 mm × 23.9 mm, and its mass is 0.61 g. Figure 1-3 shows the inner TPE compound product drawing. Its average wall thickness is 1.6 mm, overall dimensions are 5.9 mm × 9.8 mm × 22.2 mm, and its mass is 0.66 g. This mold is designed to produce 4+4 cavities per shot and has high appearance requirements, classifying it as a precision two-color mold.

Design Key Points

Parting and Ejection Direction

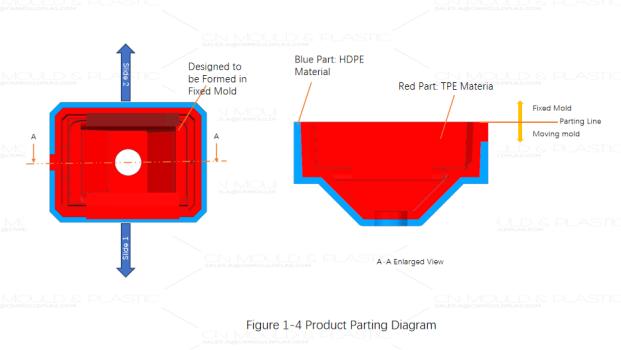

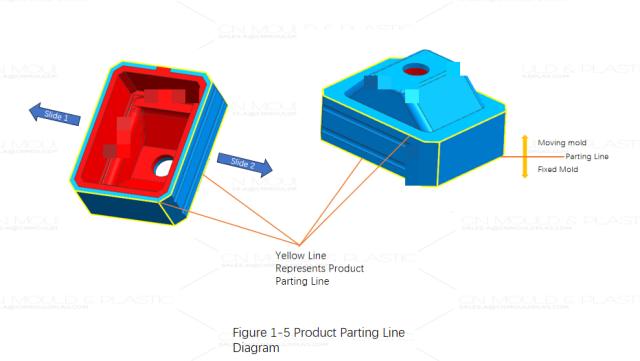

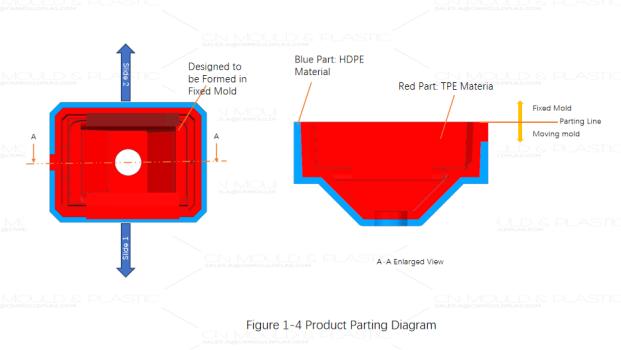

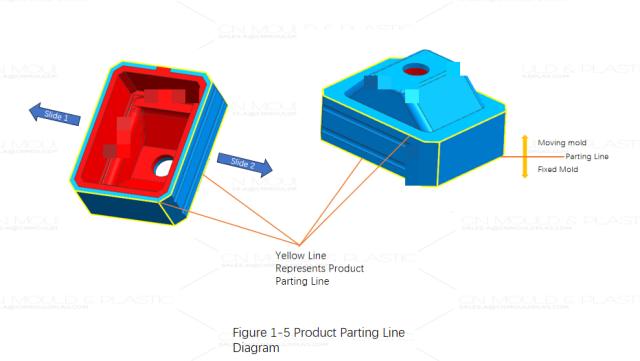

This product has no special internal structures, and the fixed and moving molds can be directly parted for injection molding. The two sides of the product have grooves, which can be formed using two slider structures. The overall product structure is simple, and the parting surface is not complex. Analyzing the product carefully: the outer layer of this two-color product is hard plastic, while the inner layer is soft plastic, whereas most two-color products have hard plastic inside and soft plastic outside. This is the unique feature of this two-color mold design.

Before analyzing the ejection direction, let’s first examine the characteristics of TPE: TPE is a thermoplastic elastomer that can be plasticized and molded at high temperatures. For this two-color product, if the first shot injects the inner soft TPE, the soft TPE product is prone to softening and deformation during the injection of the second shot (hard plastic), which could affect the bonding performance of the two materials and compromise product quality. Clearly, for this two-color product, the first shot must inject the hard HDPE compound, followed by the second shot injecting the soft TPE.

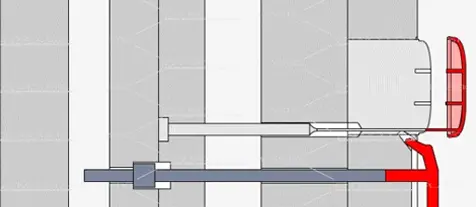

After determining the injection sequence of the first and second shots, based on the basic principles of simple two-color mold design—where the fixed mold part has different product shapes and the moving mold part is identical—the second shot (soft TPE) needs to be formed in the fixed mold. Thus, the ejection direction is determined: the side with the notch is designed on the fixed mold side, as shown in Figures 1-4 and 1-5.

Gate Setting

Figure 1-6 shows the gate diagram for the first shot (hard HDPE). A submarine gate is used at the corner of the product, which does not affect the product’s appearance and allows automatic separation. Figure 1-7 shows the gate diagram for the second shot (soft TPE), which also uses a submarine gate. However, during product design, a notch must be reserved on the side of the first shot (hard HDPE) for the gate of the second shot (soft TPE).

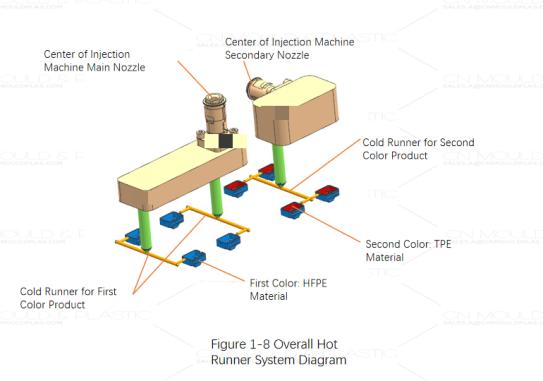

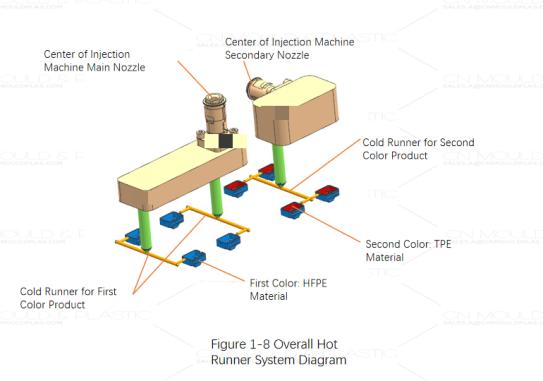

This mold is paired with an H-type two-color injection molding machine for production. The machine’s secondary nozzle is located on the top side, perpendicular to the primary nozzle. Figure 1-8 shows the overall runner system diagram.

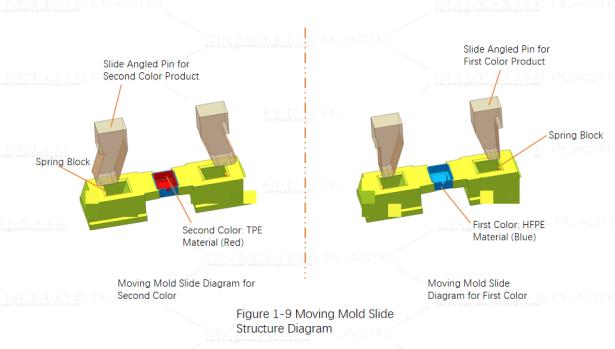

With the product gates determined, the next step is to introduce the design challenges and features of this two-color mold: how to inject the second shot (inner material) after molding the first shot product. As shown in Figures 1-4 and 1-5, the sliders of this two-color mold are designed on the moving mold side. How can it be ensured that the first shot product remains inside the moving mold without moving during the rotation from the first shot molding position to the second shot molding position?

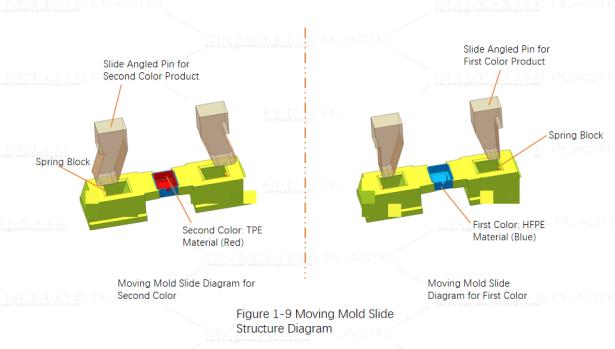

Typically, moving mold sliders are designed to be driven by fixed mold angled guide pins. In such cases, after the first shot product is molded, during the first mold opening, the fixed mold angled guide pins would drive the moving mold sliders to perform demolding and core-pulling actions, causing the moving mold sliders to separate from the first shot product. This would prevent the product from remaining stationary inside the moving mold. Therefore, conventional moving mold slider designs cannot meet the functional requirements of this two-color injection mold.

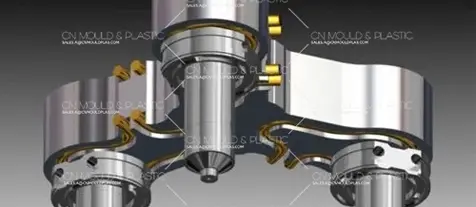

Thus, this mold uses a cam-pin structure instead of the commonly used angled guide pin structure. Additionally, the cam-pin designs for the first and second shot products are modified to achieve the required functionality of this two-color mold. Figure 1-9 shows a schematic diagram of the moving mold slider structure. By modifying the cam-pin designs for the first and second shot products and adding an elastic block mechanism inside the slider, the moving mold slider remains stationary during the first mold opening. The secured first shot product rotates with the moving mold to the second shot molding position.

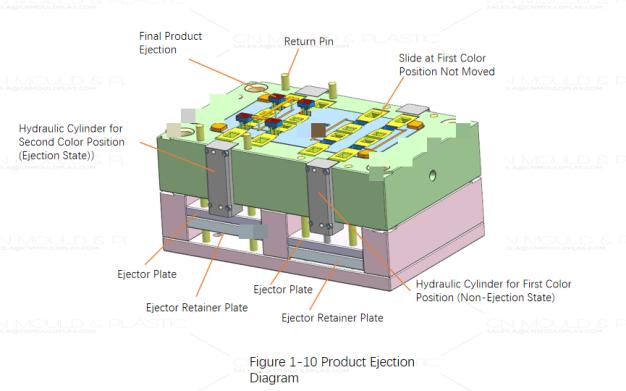

Product Ejection

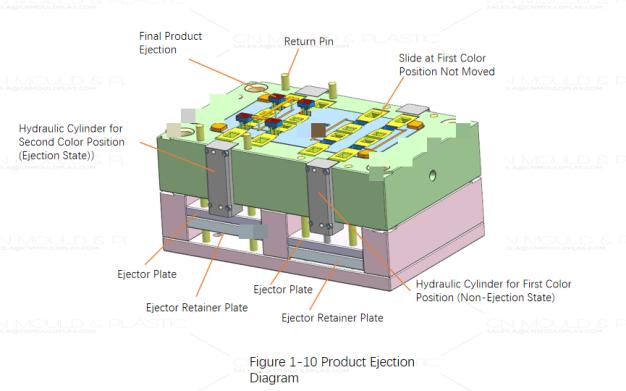

The product ejection for this mold is relatively straightforward. A hydraulic cylinder at the second shot position pushes the second shot’s ejector plate and ejector retainer plate, ultimately ejecting the product and runner via ejector pins mounted on the ejector plate, as shown in Figure 1-10. During this process, the hydraulic cylinder and ejector plate at the first shot position do not participate in the ejection action. The first shot product remains on the moving mold slider and moving mold core without being ejected.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk