Product Description

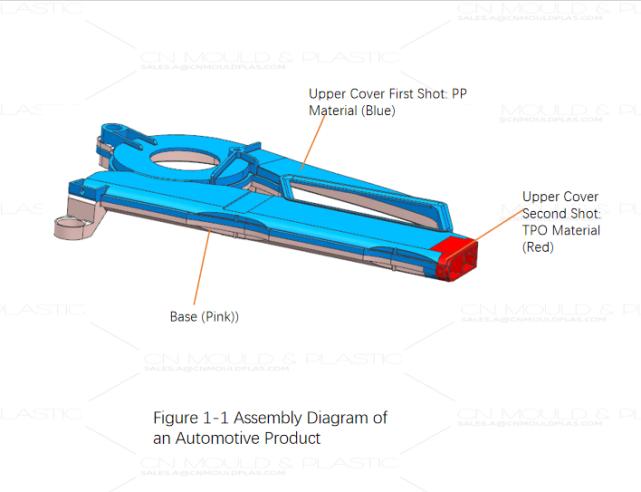

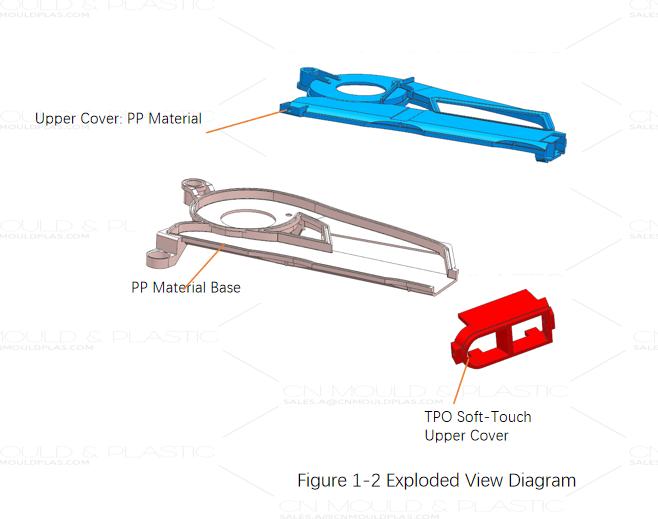

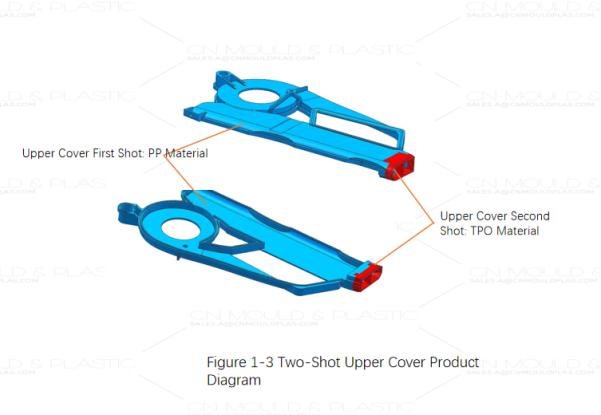

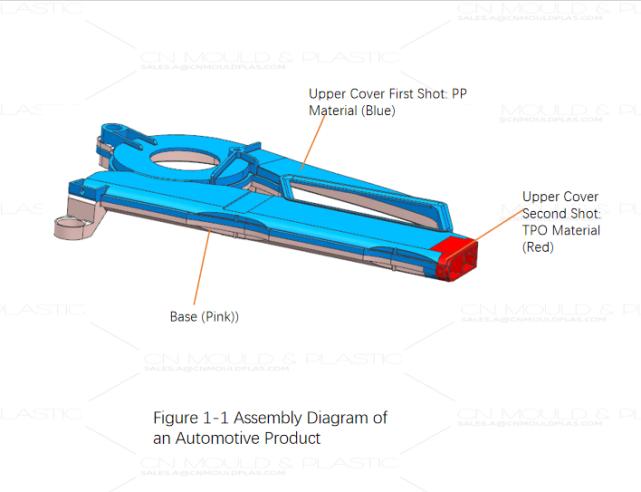

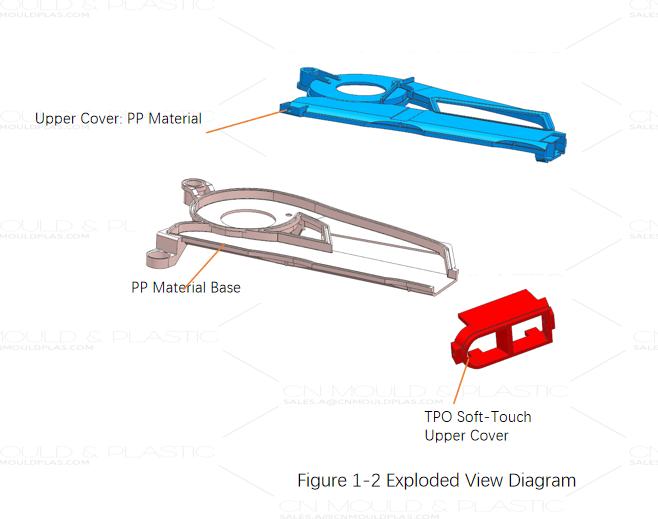

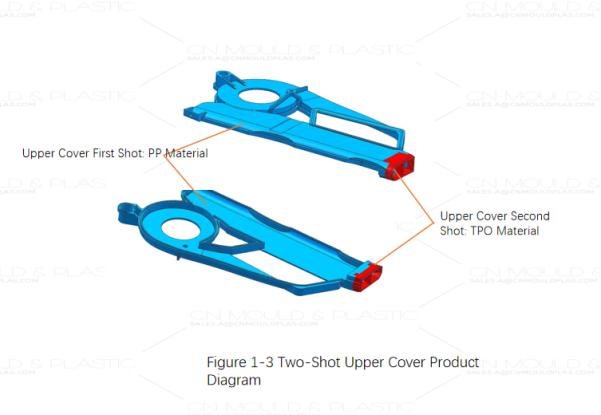

Figure 1-1 shows an assembly drawing of an automotive interior component. This part consists of three sub-components: an upper cover (PP material), a base (PP material), and a TEO component (elastomer, soft touch), as shown in Figure 1-2. The design is now modified to consolidate the TEO elastomer and upper cover into a single part via two-shot molding, as shown in Figure 1-3. Both the upper cover and base must be injection molded in the same tool.

The upper cover has an average wall thickness of 2.5 mm and overall dimensions of 135.6 mm × 142.7 mm × 378.5 mm. The green section represents the first shot (PP), weighing 126 g, while the orange section is the second shot (TEO elastomer), weighing 34 g. The base has an average wall thickness of 2.5 mm, overall dimensions of 125.8 mm × 139.1 mm × 334.9 mm, and weighs 96 g.

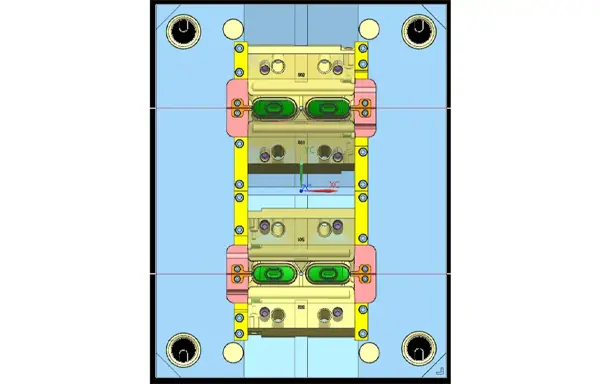

The mold is designed for a 2+1 cavity layout: the first shot produces 2 parts, and the second shot produces 1 part. This results in one single-color base and one two-shot upper cover with soft-touch elastomer per cycle.

Design Highlights

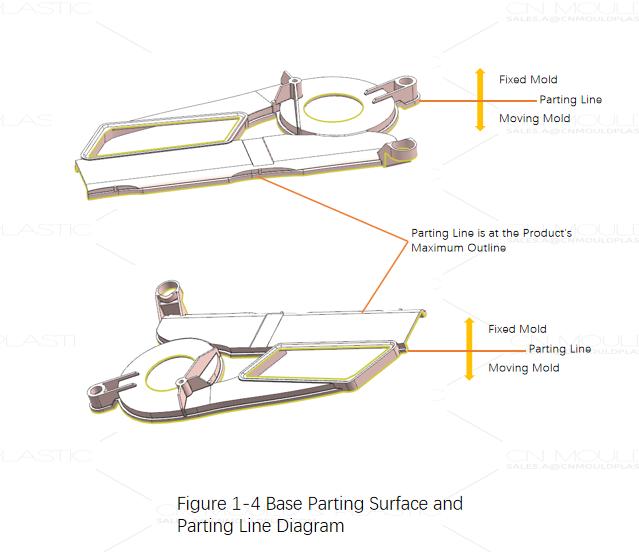

Parting Line and Ejection Direction

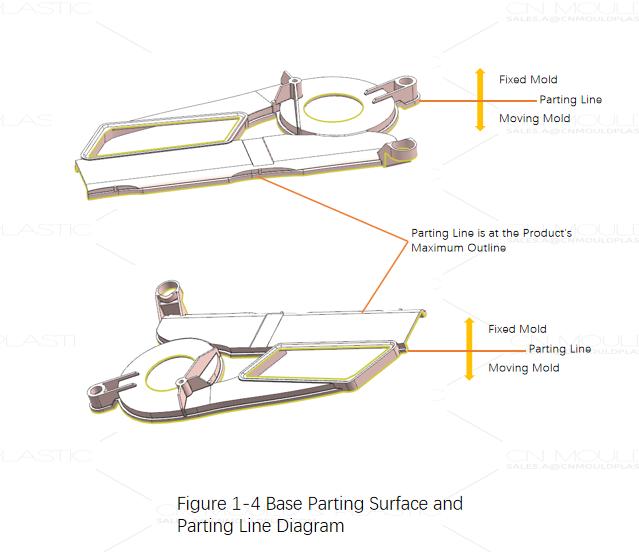

The ejection direction and parting line must be determined before mold design. The base is a simple single-shot part, so the parting line directly follows its maximum contour. Figure 1-4 shows the base's parting line and ejection direction.

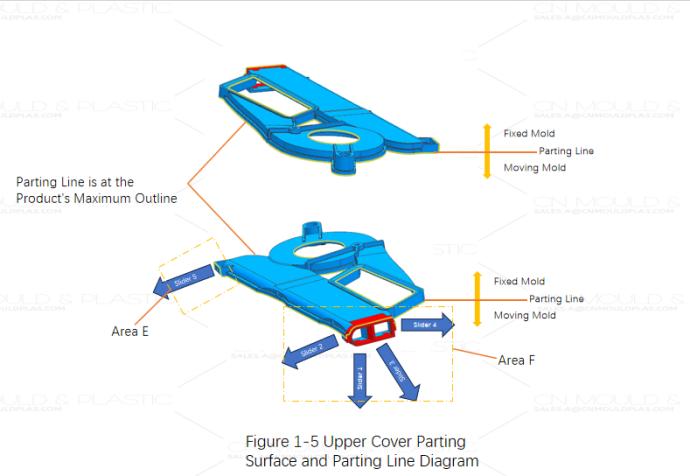

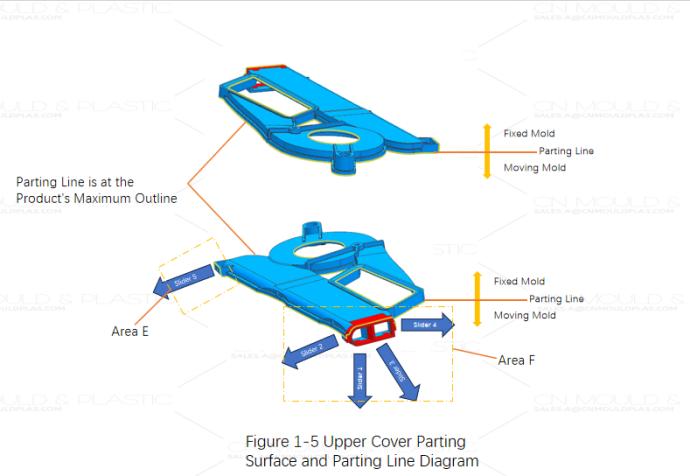

The upper cover is more complex. Figure 1-5 shows its parting surfaces and parting lines. Based on plastic part design experience, Area F (see Figure 1-5) is the core of this mold design. This area has undercuts on three sides, requiring multiple sliders for forming. Area E is relatively simpler and can be handled with a single slider.

Gate Design

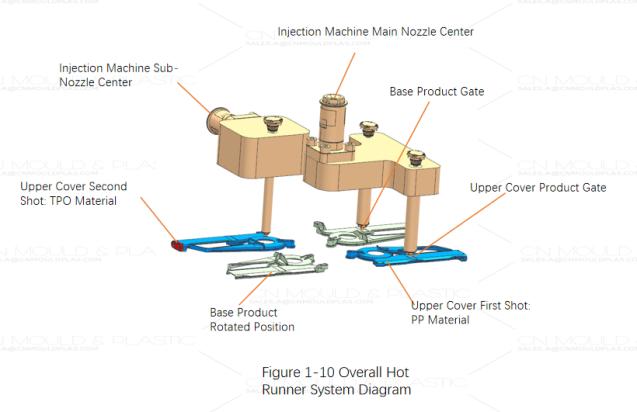

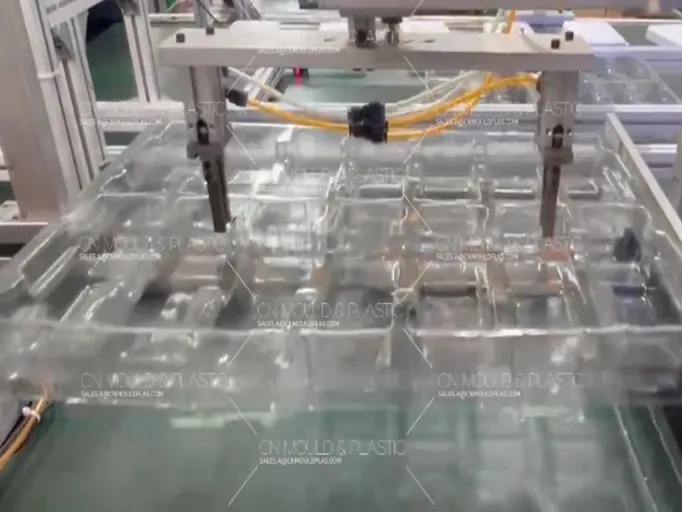

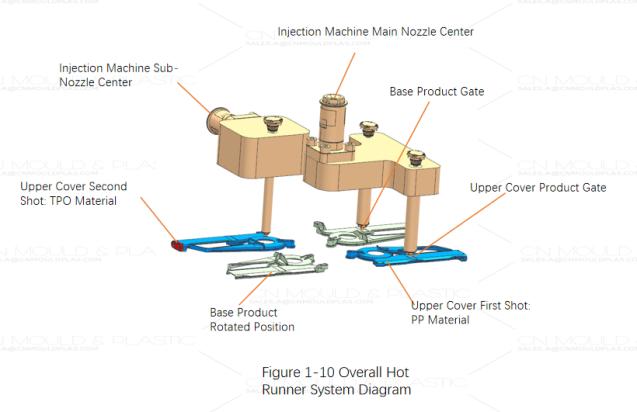

The mold is paired with an injection machine featuring a rotating moving platen, allowing a standard two-shot rotating mold design. This H-type two-shot machine has the primary nozzle in the standard position and the secondary nozzle on the top side, perpendicular to the primary nozzle.

Analyzing the product features determines the gate type and location. This 2+1 cavity mold means only the upper cover undergoes two-shot molding; the base is complete after the first shot. Thus, the second-shot hot runner system only serves the TEO elastomer for the upper cover. When the mold rotates to the second station, the base is not involved, so no corresponding cavity is needed on the fixed half.

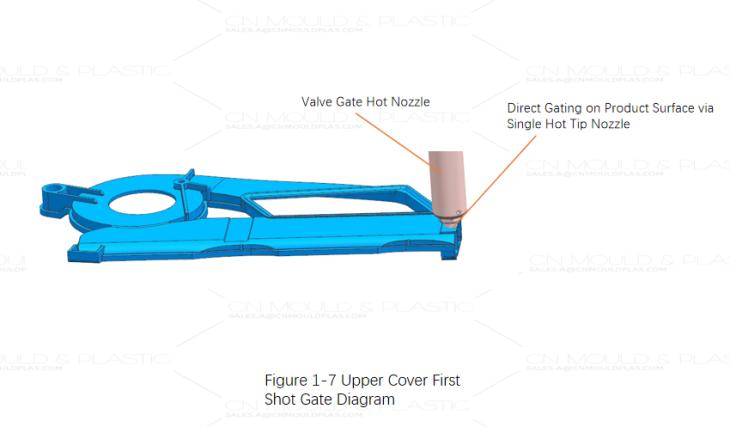

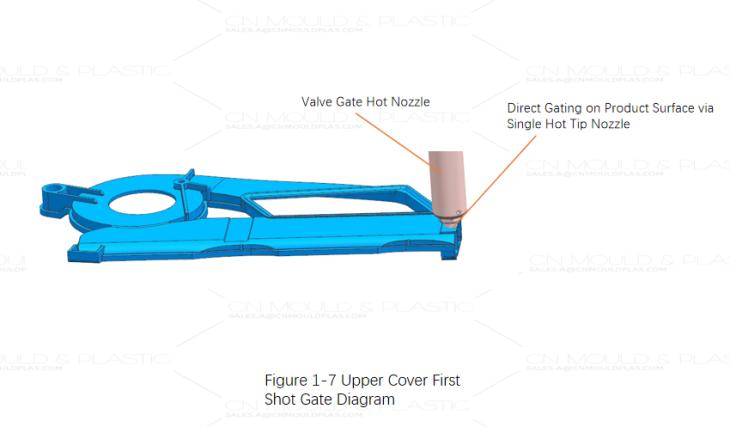

Area A on the upper cover (see Figure 1-6) has a smooth surface that will be covered by the second-shot TEO elastomer, making it ideal for gating. The part is not excessively large, and the first-shot PP has good flow properties. Therefore, a single valve-gated hot nozzle is suitable for the first shot, as shown in Figure 1-7.

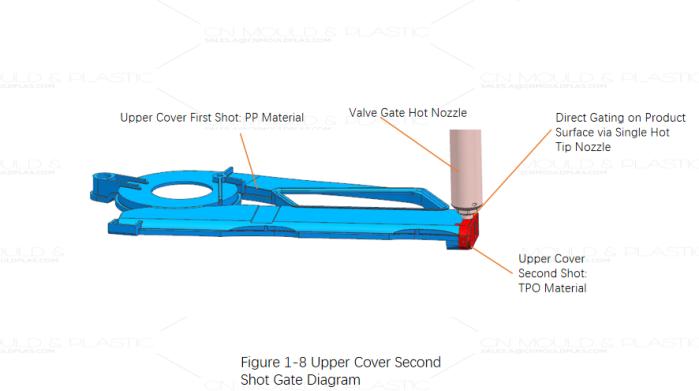

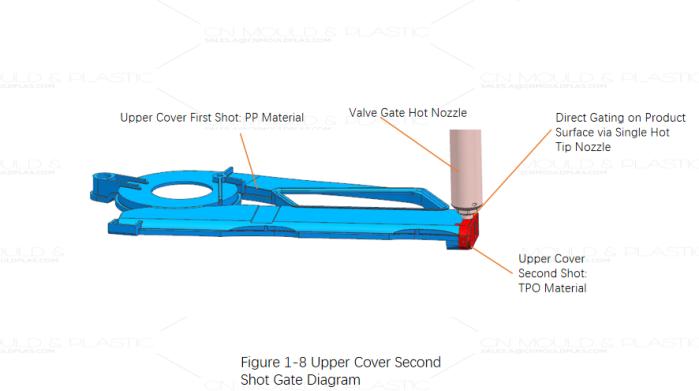

The second-shot TEO elastomer volume is small and can also be gated via a single valve-gated hot nozzle, as shown in Figure 1-8.

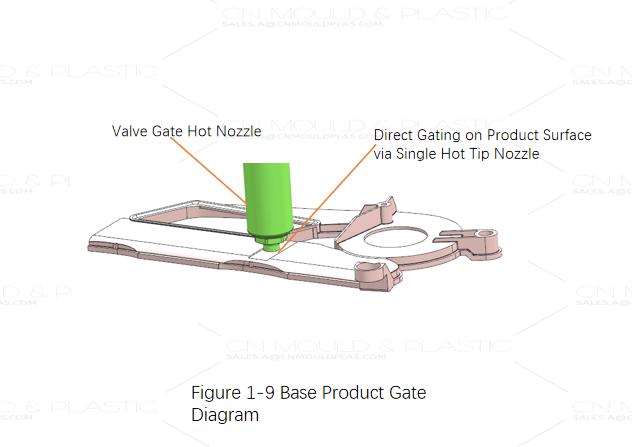

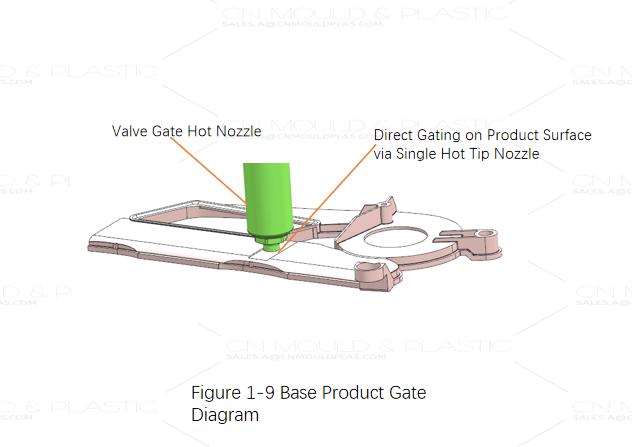

The base is a single-shot PP part and can be molded using a single valve-gated hot nozzle directly on its surface, as shown in Figure 1-9.

Important Note: Since the base surface is curved at the gate location, the hot nozzle must include an anti-rotation feature to prevent alignment issues during maintenance that could cause surface imperfections.

Figure 1-10 shows the complete hot runner system and gate layout for the entire mold.

Mold Structure Details

With the gates defined, the complex details of this two-shot mold structure can be analyzed. This design is not only unique but also challenging. Clearly, the part does not meet the basic principle of simple two-shot molds (different geometries on the fixed half, identical on the moving half), ruling out a standard two-shot design.

Firstly, the mold uses a 2+1 cavity layout where the upper cover is two-shot, and the base is single-shot. Secondly, the second shot of the upper cover is not entirely formed in the fixed half but involves both fixed and moving halves, significantly increasing complexity.

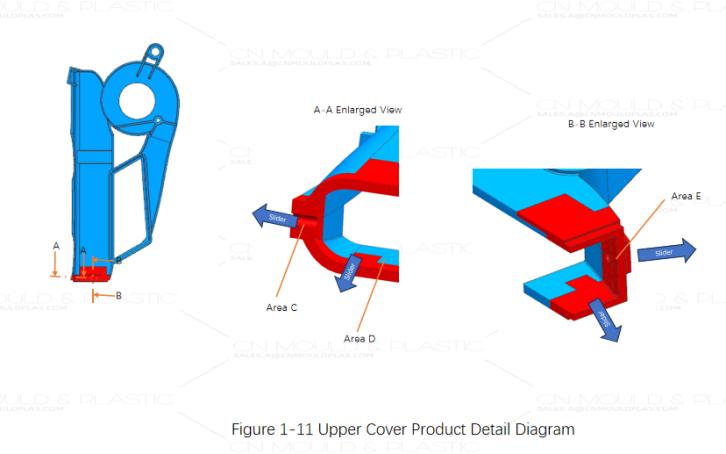

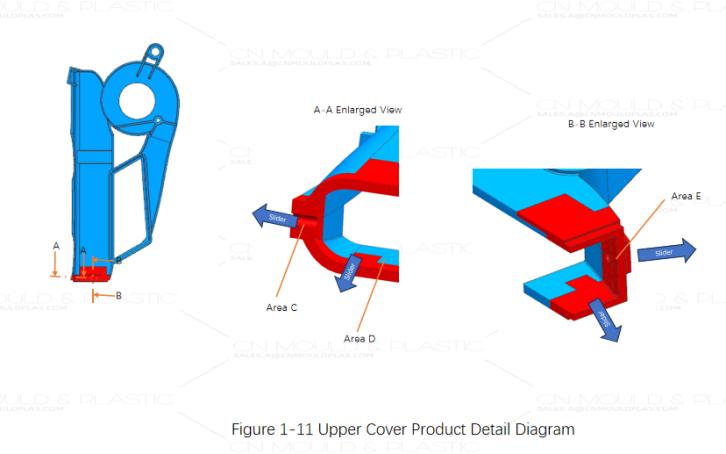

Analysis shows that the second-shot features of the upper cover prevent simple formation directly by the fixed and moving halves. A fixed-half slider is required. Closer examination of Areas C, D, and E (see Figure 1-11) reveals that a single fixed-half slider cannot achieve demolding; a combination of sliders within the main fixed-half slider is necessary for core-pulling in this region.

Therefore, the second-shot TEO elastomer for the upper cover must be formed using a fixed-half slider with internal sub-sliders.

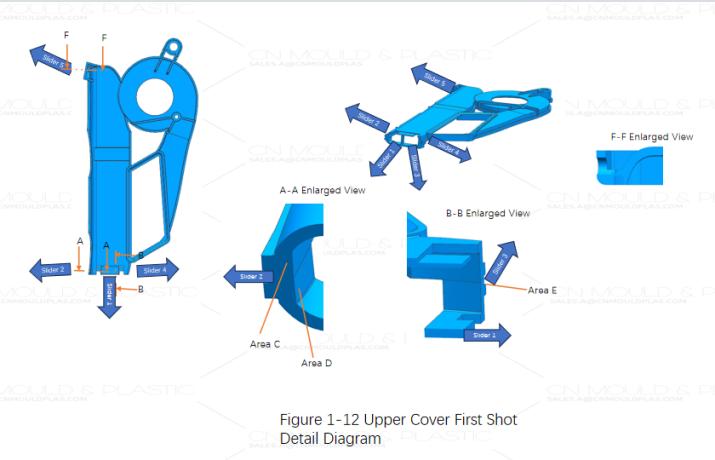

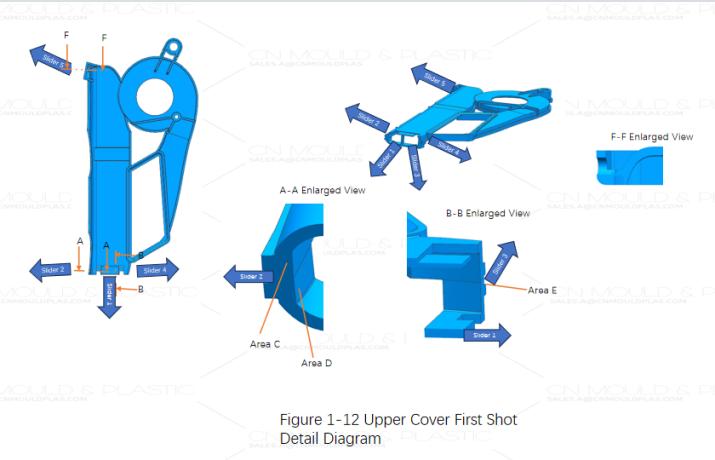

After defining the second-shot formation method, the structure of the first-shot PP upper cover is analyzed. As shown in Figure 1-12, Areas C and E of the first-shot part also contain undercuts requiring sliders (see Section B-B, Figure 1-12). Since the undercut direction also necessitates sliding action, a design with one main slider driving three internal sub-sliders (Internal Sliders 2, 3, and 4 within Main Slider 1) is adopted. This is known as a fixed-half slider with integrated sub-slider structure.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk