In the world of injection molding, achieving high precision and durability in multi-material components requires meticulous attention to mold design, material selection, and process control. Today, we’re diving into the technical details of a two-color mold used for producing a dual-material product—where the first color is HDPE and the second is TPE.

Mold Material Specifications & Heat Treatment

To ensure longevity and performance under cyclic thermal and mechanical stress, critical mold components are made from premium steels and undergo precise heat treatment:

Hot Runner System: HRS brand.

Fixed Mold Cavity: Material – 1.2343 ESR. Heat treatment – hardened and double tempered, hardness 48–50 HRC.

Moving Mold Core: Material – 1.2343 ESR. Heat treatment – hardened and double tempered, hardness 46–48 HRC.

Sliders: Material – 1.2343 ESR. Heat treatment – hardened and double tempered, hardness 46–50 HRC.

Inserts: Material – 1.2343 ESR. Heat treatment – hardened and double tempered, hardness 46–50 HRC.

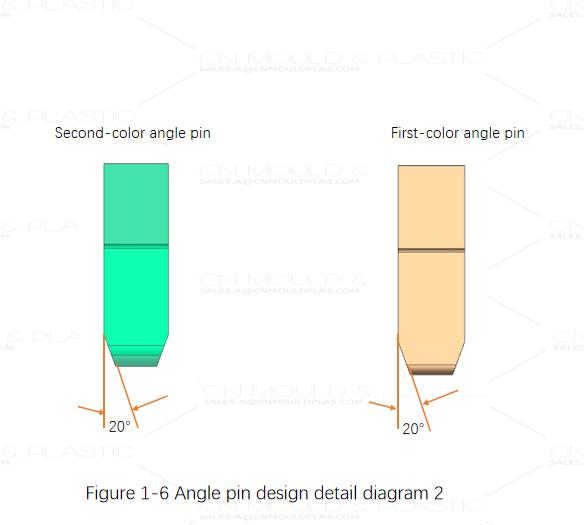

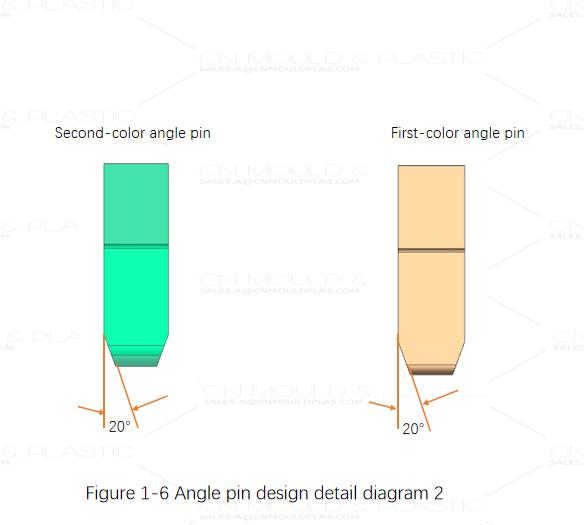

Angle Pins: Material – 1.2344. Heat treatment – hardened and double tempered, hardness 46–50 HRC.

Other Standard Components: HASCO brand standard parts.

These carefully selected materials and treatments ensure wear resistance, dimensional stability, and extended mold life.

Step-by-Step: The Two-Color Molding Process

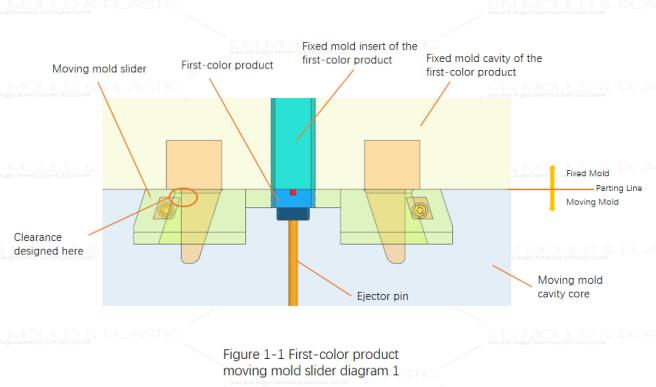

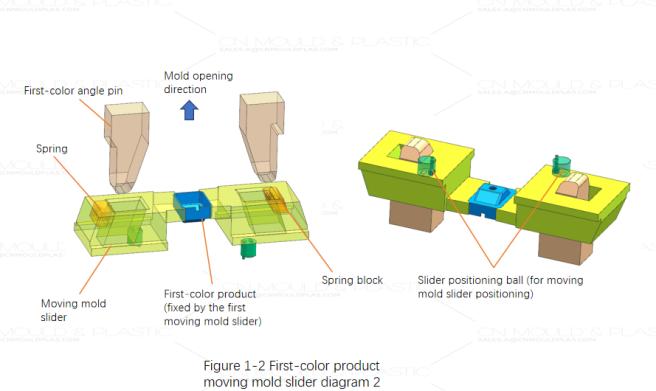

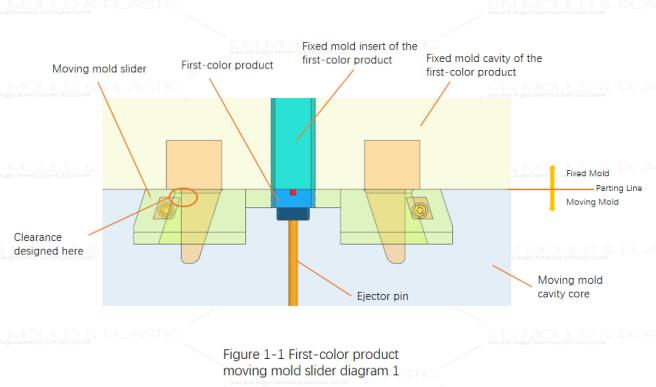

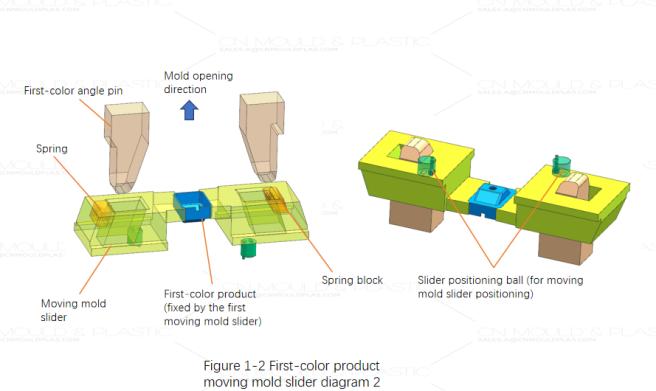

Step 1: First Color Injection

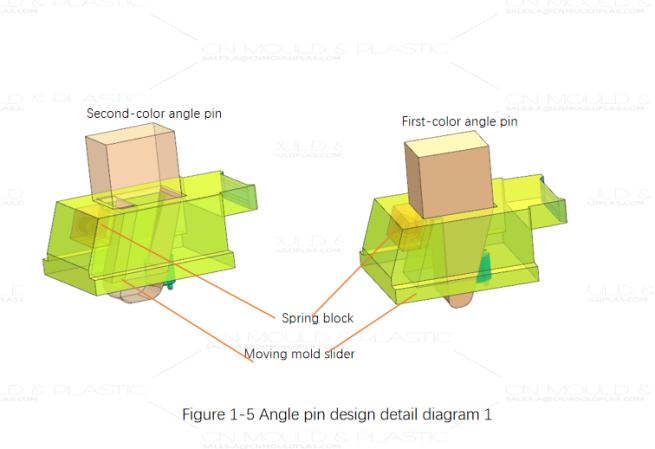

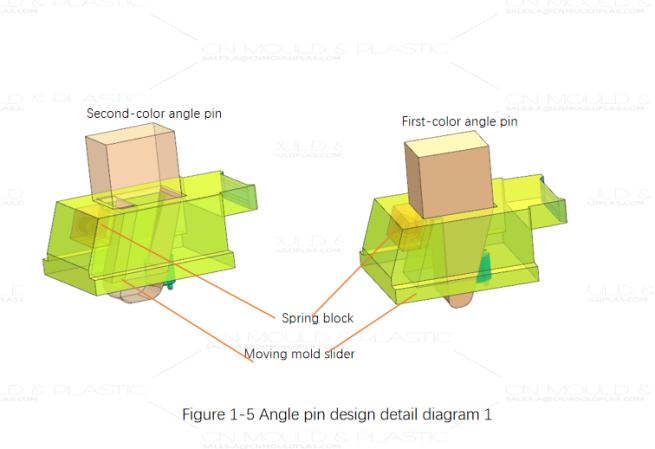

After the first color (HDPE) is injected and cooled, the mold opens for the first time. During this opening, the first-color angle pin does not engage with the moving mold slider or the spring block. Thus, the slider remains in its original position, secured by the slider positioning ball (see Figures 1-1 and 1-2).

Step 2: Mold Rotation

The moving mold then rotates 180° to the second-color (TPE) injection position. Throughout this rotation, the first-color product remains securely held by the slider and moving core, preventing any displacement.

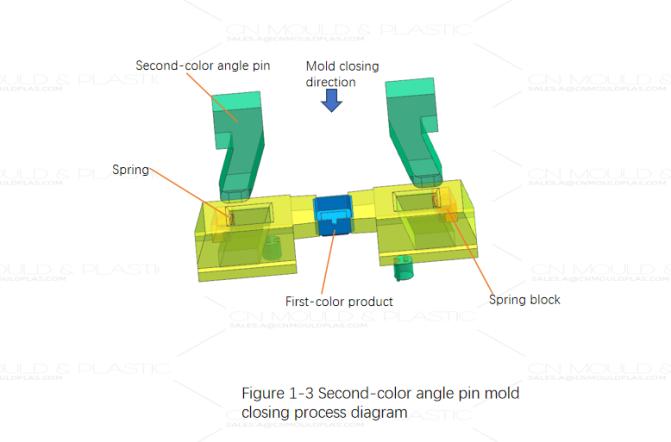

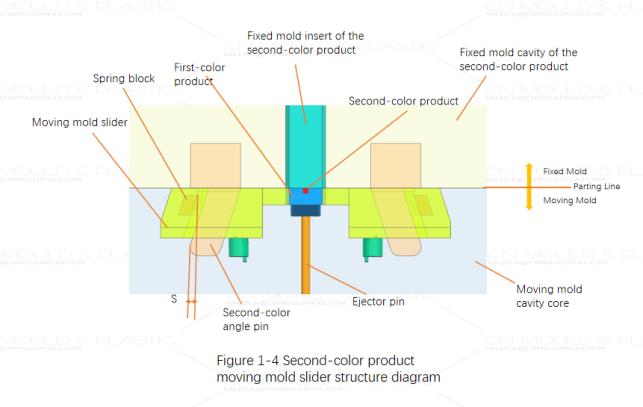

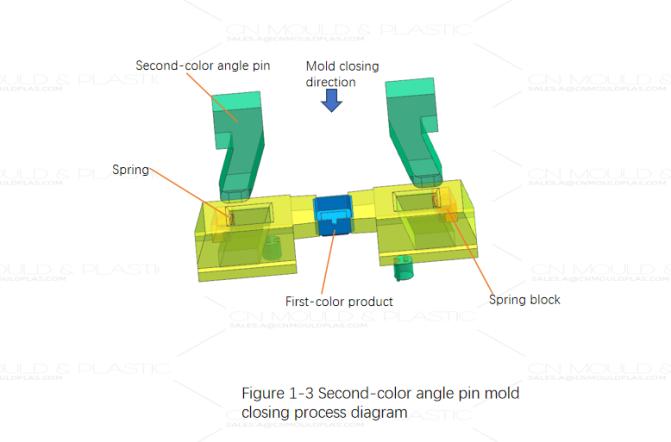

Step 3: Second Mold Closing

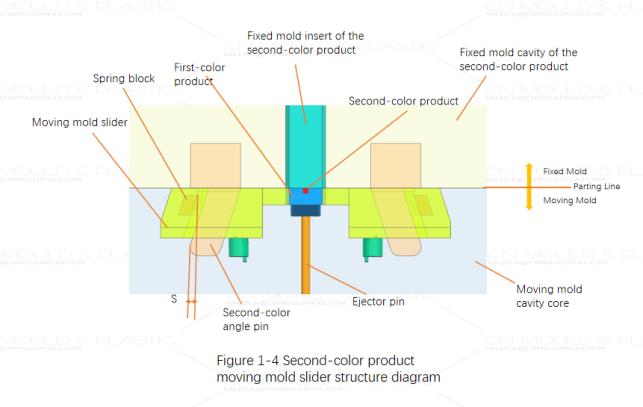

Once in position, the mold closes for the second time. During closing, the second-color angle pin presses against the spring block inside the slider. The spring compresses, allowing the angle pin to move into its working position and lock the slider in place (see Figures 1-3 and 1-4). The mold is now ready for TPE injection.

Step 4: Second Color Injection & Ejection

After TPE injection and cooling, the mold opens again. This time, the second-color angle pin engages with the spring block, driving the slider to move a distance S (see Figure 1-4) to release the core. Once fully open, ejector pins push out the finished two-color product, completing the cycle

Production Efficiency

In actual production, the first and second colors are molded simultaneously within each cycle. With every mold opening and closing, and one rotation of the moving mold, four first-color parts and four complete two-color products are produced.

Key Design Considerations

Angle Pin Design:

To ensure smooth entry into the slider, the tip of the angle pin is designed with a relatively large angle—typically around 20° (refer to Figures 1-5 and 1-6).

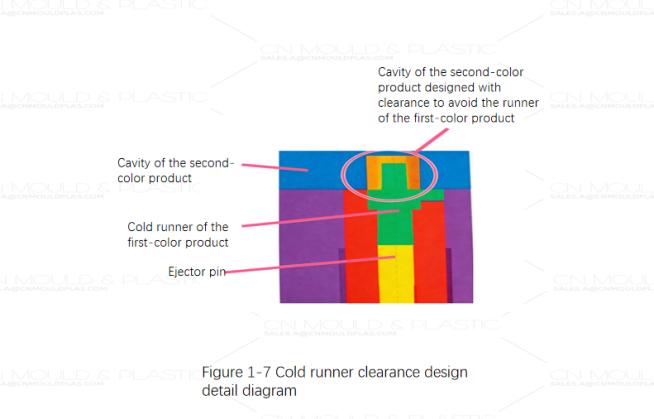

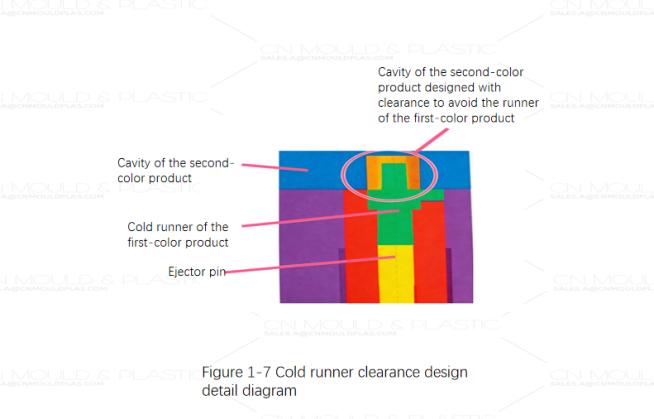

Clearance for Cold Runner:

Since the cold runner of the first-color part is not ejected after the first injection but rotates with the mold to the second injection station, the corresponding area in the second-color cavity must be designed with adequate clearance. This prevents the second-color cavity from crushing the first-color cold runner (see Figure 1-7).

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk