Product Description

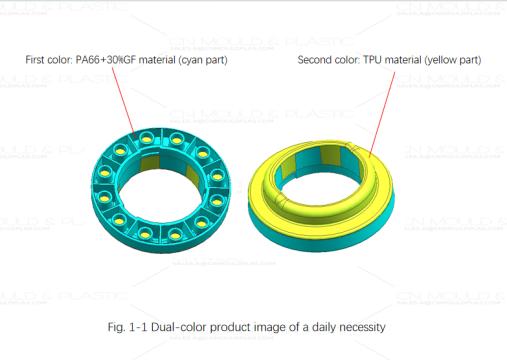

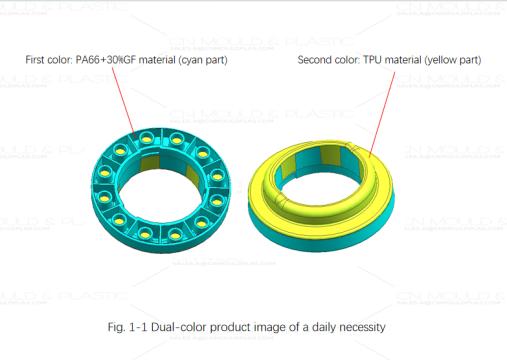

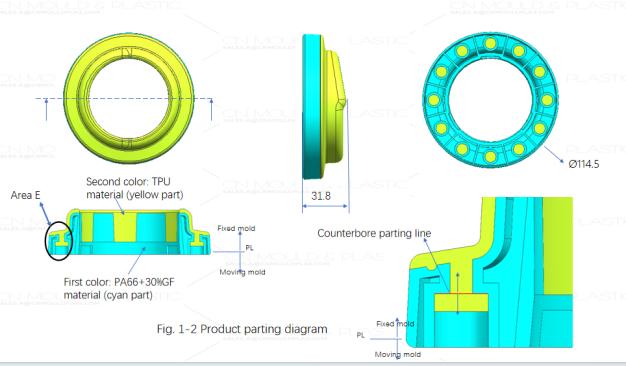

Figure 1-1 shows a two-color product drawing of a daily item. The first color, green, is made of PA66 + 30% GF compound, and the second color, orange, is made of TPU compound (soft rubber). The product has an average wall thickness of 3mm and overall dimensions of 114.5mm x 31.8mm. The mass of the first-color PA66+30%GF compound is 63.5g, and the mass of the second-color TPU compound is 15.6g. This mold is designed for a 4+4 cavity layout on the first level.

Design Key Points

Parting and Ejection Direction

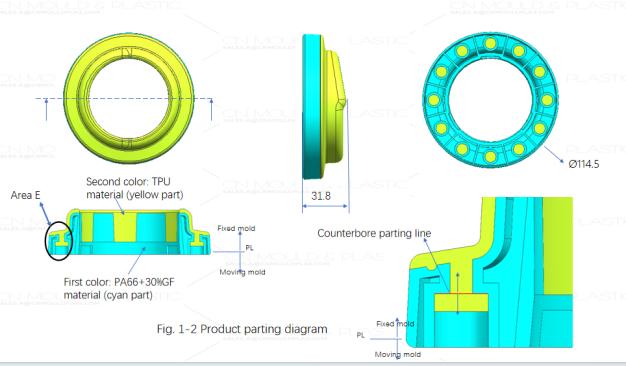

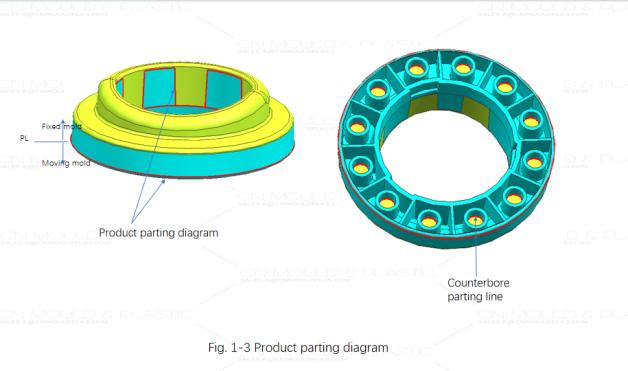

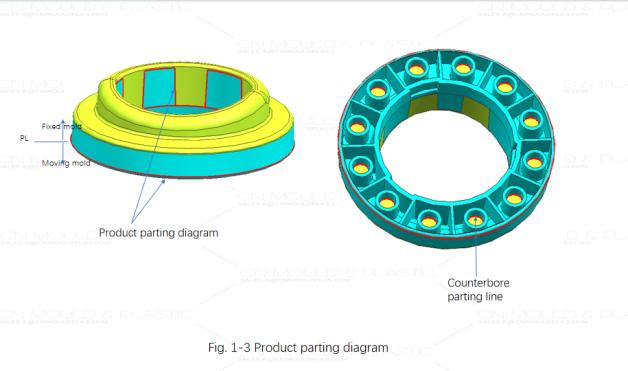

First, analyze the product's internal structure. During product design, to ensure stronger adhesion between the second-color compound and the first-color compound, some countersunk holes were designed on the first-color product (see enlarged view of Area E in Figure 1-2). Without these holes, this two-color product would be a simple two-color mold product, fully conforming to the basic design principle for simple two-color molds: the shapes in the fixed mold half (cavity side) are different, while those in the moving mold half (core side) are identical. The addition of these countersunk holes means that part of the second-color TPU soft rubber needs to be formed in the moving mold cavity, increasing the difficulty of designing this two-color mold. Therefore, if this two-color product is designed for a two-color mold, the parting line for the countersunk holes must run through the middle of the holes, with parts formed in both the fixed and moving molds. The mold structural design at this location is the characteristic and challenging aspect of this two-color mold design. Figure 1-3 shows the parting line diagram for this product.

Gate Setting

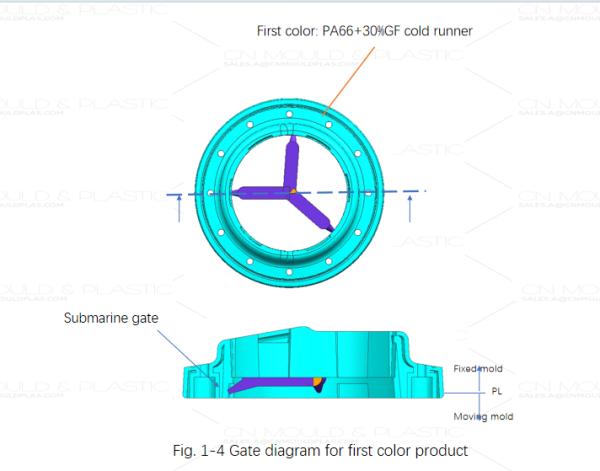

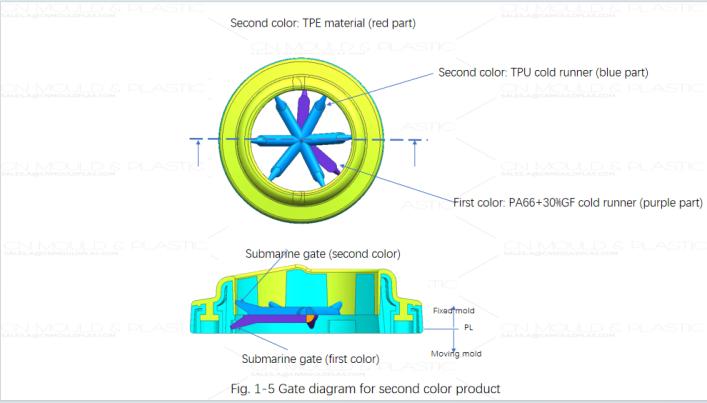

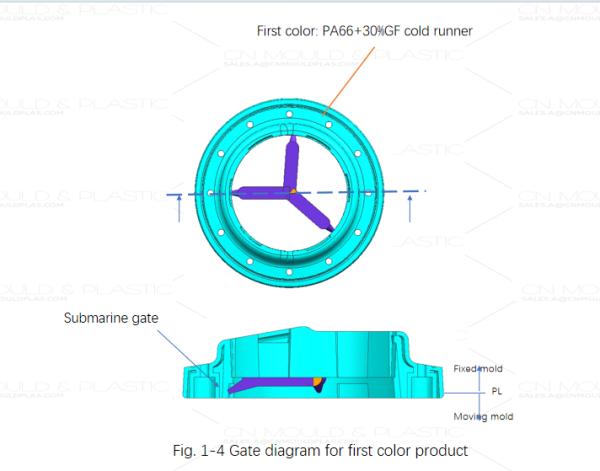

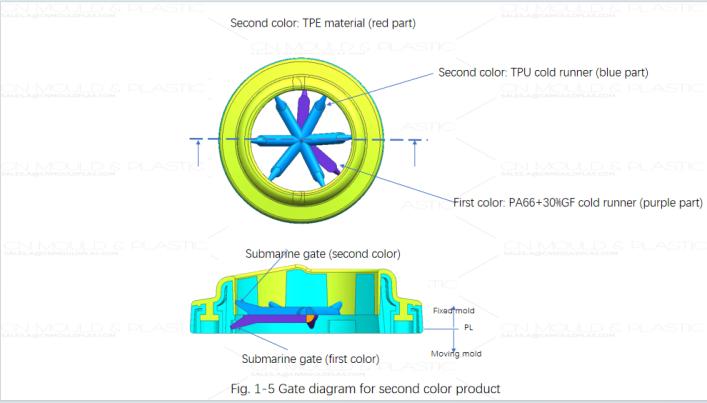

This product is circular, and the first-color PA66+30%GF compound is prone to causing product deformation. Therefore, it was decided to use a hot runner system transferring to three-point submarine gates for the first-color product, as shown in Figure 1-4. For the second-color TPU compound, a hot runner system transferring to five-point submarine gates is used, as shown in Figure 1-5. After the first-color injection molding is completed in this mold set, the runner of the first-color product remains in the moving mold core, serving to seal the runner for the second-color product.

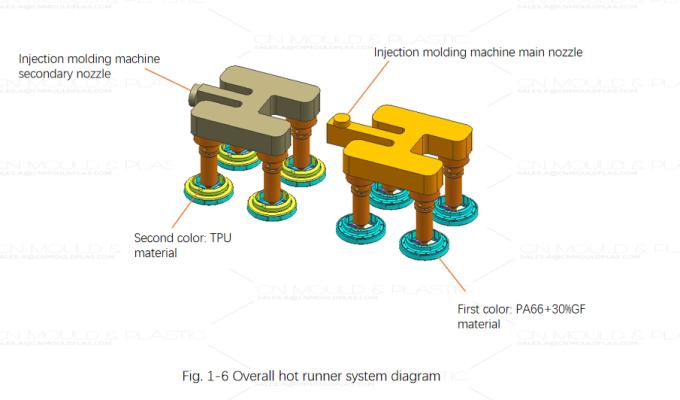

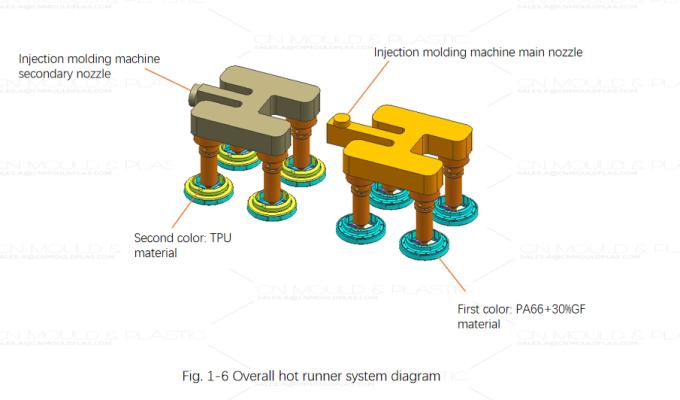

The injection molding machine paired with this two-color mold is an H-type two-color machine. The main injection nozzle is in the normal position, and the secondary injection nozzle is located on the top side (sky side) of the machine, perpendicular to the main nozzle. Figure 1-6 shows the hot runner system diagram for the entire mold set.

As seen in Figure 1-2, the product structure is simple and belongs to a simple two-color product. The key point is how to design the second-color forming structure for the countersunk holes in the enlarged partial view (Area E). In the enlarged view of Area E, part of the second-color compound for the countersunk holes is formed in the fixed mold cavity, and part is formed on the moving mold core. As previously mentioned, the typical mold structure to solve this product design involves designing a moving mold slide mechanism, i.e., an internal slide within the moving mold core, then using a hydraulic cylinder or angle pin to drive the internal slide to switch its position between the first-color and second-color forming stages, thereby achieving two-shot two-color injection molding.

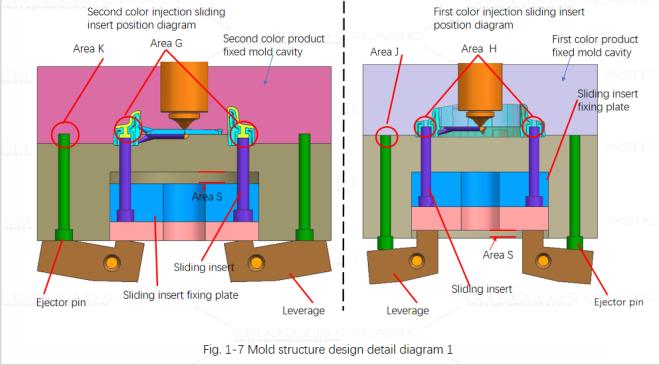

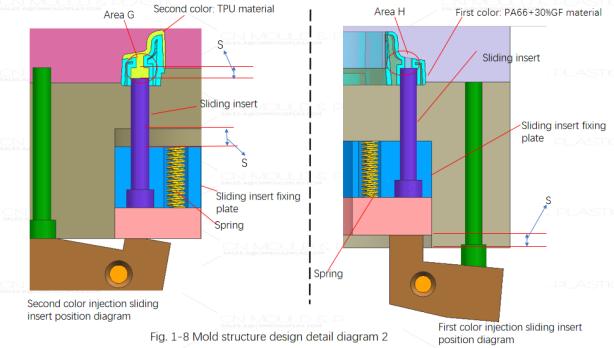

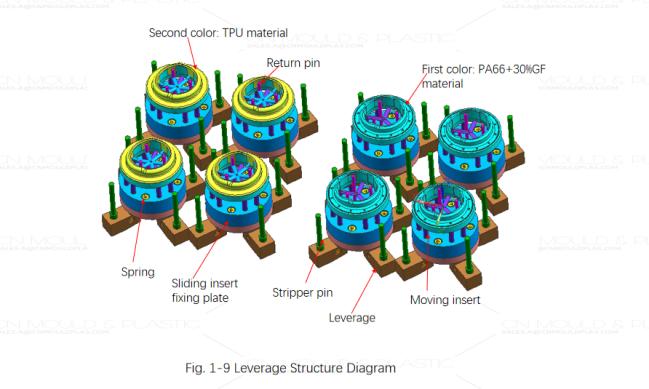

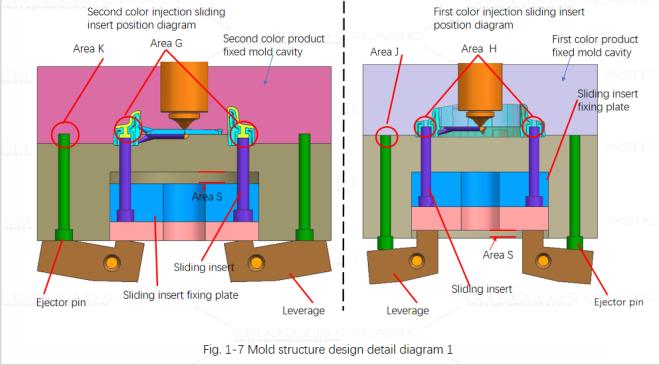

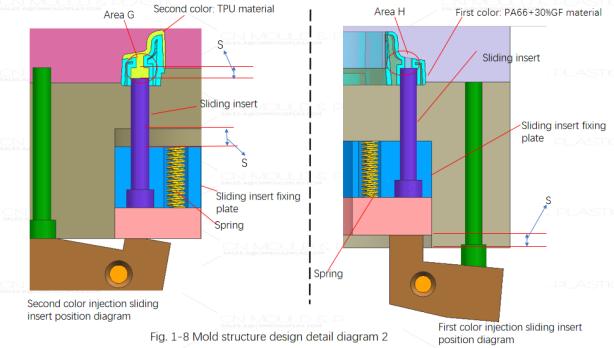

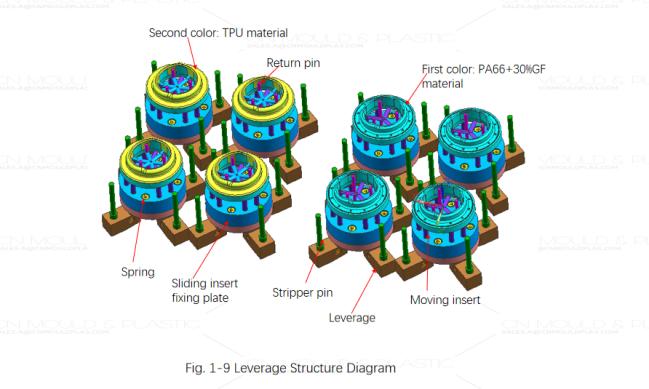

Here, another mold structure to achieve the positional switch for these countersunk holes between the first and second colors is introduced — the seesaw structure. The following focuses on how theLeverage structure realizes the transformation between the first-color cavity and the second-color cavity. Figures 1-7 and 1-8 show detailed design drawings of this mold structure.

At the start of the first-color product injection molding, the fixed mold cavity for the first-color product contacts the ejector pin on the moving mold (see Figure 1-7), causing theLeverage to tilt. This movement shifts the sliding insert plate and the sliding insert by a distances (see Figure 1-8), positioning the sliding insert at the molding location for the first-color product (Area H in Figure 1-7).

After the first-color product molding is complete, during mold opening between the fixed and moving mold halves, the spring (see Figure 1-8) causes the sliding insert to move back by distances, reaching the molding location for the second-color product (Area G in Figure 1-7). Then, the moving platen rotary table of the injection molding machine rotates the moving mold 180 degrees, bringing the moving mold core to the second-color product molding position. The machine performs the second mold closing action. Because a clearance is designed in the second-color product's fixed mold cavity corresponding to the position of the moving mold return pin, the fixed mold cavity will not contact the ejector pin (see Area K in Figure 1-7). This achieves the transformation between the two-color cavities, allowing for the injection molding of the second-color product. Figure 1-9 shows the main structural diagram of thisLeverage mechanism.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk