Product Description

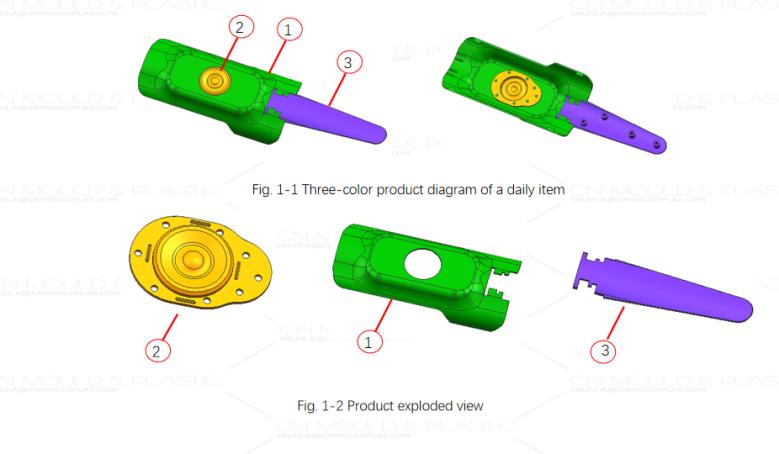

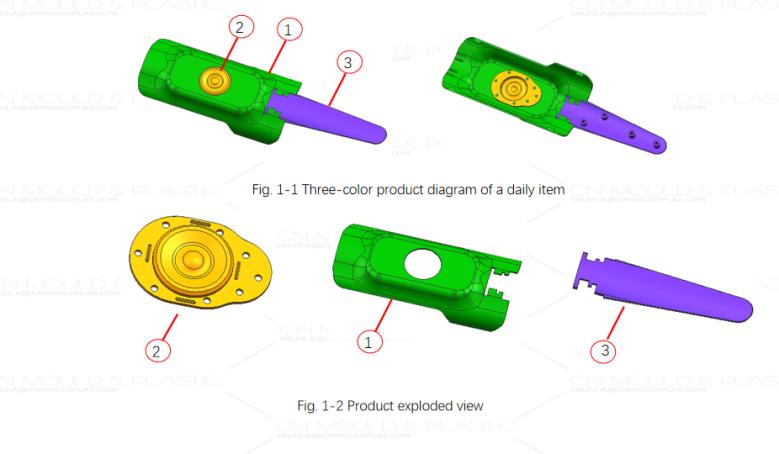

Figures 1-1 and 1-2 show a three-color product diagram and an exploded view of a daily item, respectively. The color components are as follows:

First color green ①: ABS material

Second color orange ②: TPE material (soft rubber)

Third color purple ③: ABS material

The average wall thickness of this three-color product is 0.8 mm, with overall dimensions of 115.93 mm × 24.26 mm × 13.82 mm. The material weights are:

First color material weight: 1.96 g

Second color material weight: 0.43 g

Third color material weight: 0.66 g

This mold is designed to produce the three-color product in a single cycle, with high demands on product appearance, classifying it as a precision thin-wall two-color mold.

Key Design Points

The product structure is not complex, and the mold design is relatively straightforward. The product adheres to the basic principle of simple two-color mold design: the shapes differ in the fixed mold half but are identical in the moving mold half. Unlike the two-color products described in previous chapters, this product incorporates an additional color. However, some factories lack three-color injection molding machines and only possess two-color machines. This section introduces a method to achieve three-color injection molding using a two-color machine by combining two-color injection molding with overmolding (insert molding). This mold design has wide applications in factory production and manufacturing processes.

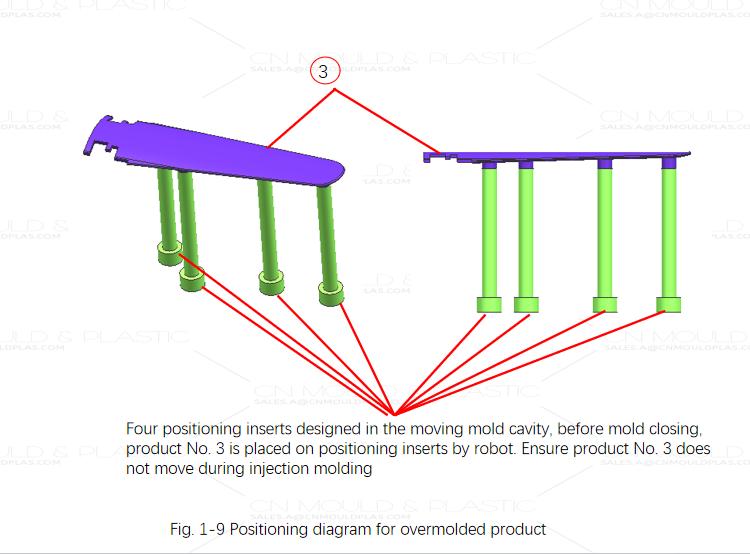

The design concept for this mold is as follows: Achieve three-color injection molding through mold configuration. First, design and manufacture a standard single-color mold to produce product No. ③ with a gate diameter of 2.5 mm. The second mold is a two-color + overmolding mold. This mold uses a two-color polymer setup. Before injection, product No. ③ is placed into the mold cavity, which constitutes the typical overmolding process.

1.2.1 Parting and Ejection Direction

As previously mentioned, two sets of molds are designed for this three-color product. The first set is a standard single-color injection mold for product No. ③. The following focuses on the design of the second set—the two-color molding mold.

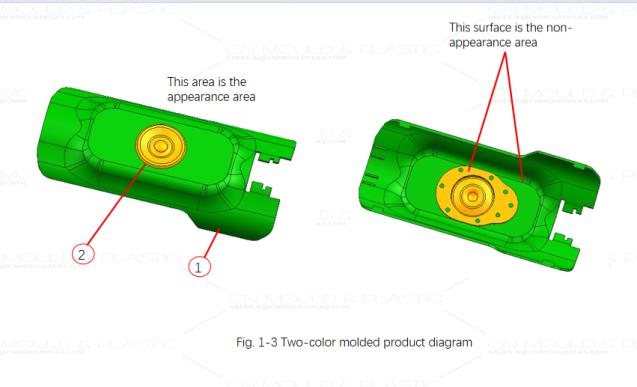

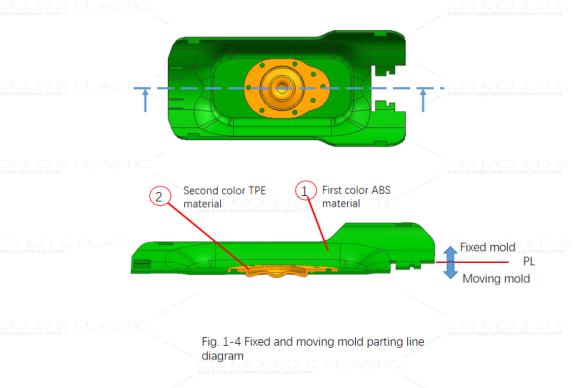

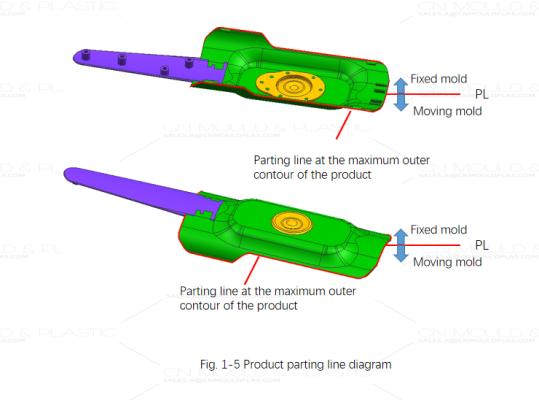

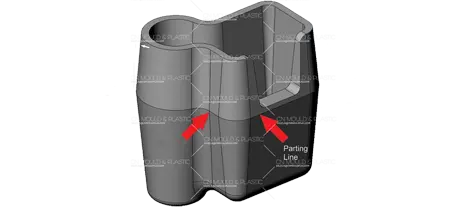

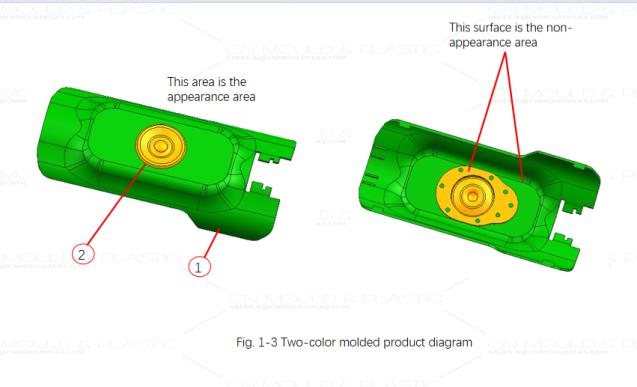

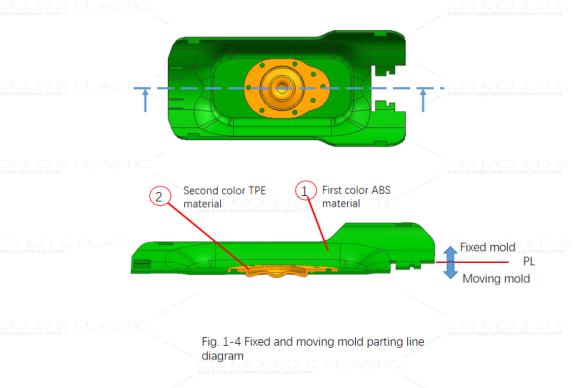

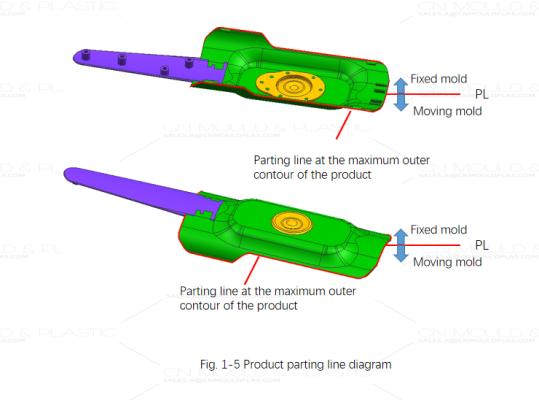

Figure 1-3 shows the two-color molded product diagram, depicting products No. ① and No. ② to be molded by this two-color mold. Here, No. ① is the first color (ABS material), and No. ② is the second color (TPE material). Due to stringent appearance requirements for the second color—requiring no flow lines or whitening marks—the design for the second color must be confined to non-appearance areas of the product. According to the product structure and fundamental two-color mold design principles, the gate and ejector pins for the first color must also be located on the fixed mold side, within its non-appearance area. Figure 1-4 shows the parting diagram between the fixed and moving mold halves, illustrating a common steel plate mold structure. Figure 1-5 indicates the product's maximum outer contour line, which serves as the parting line.

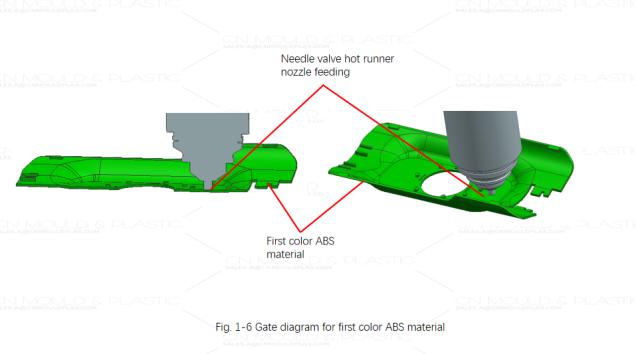

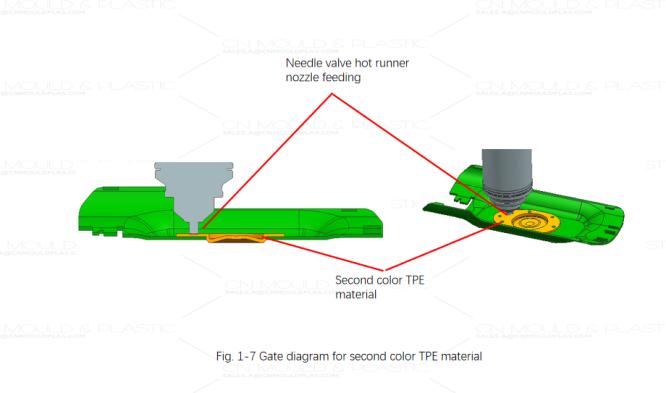

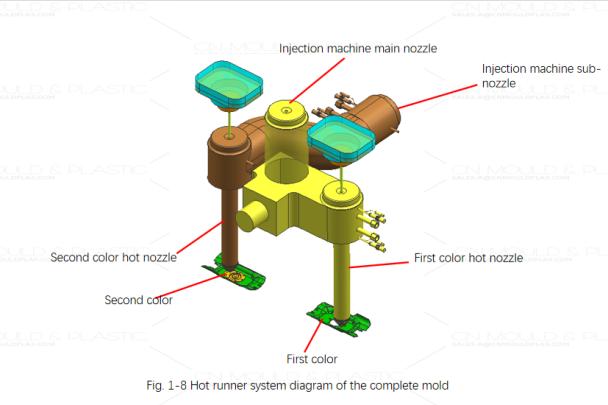

1.2.2 Gate Setting

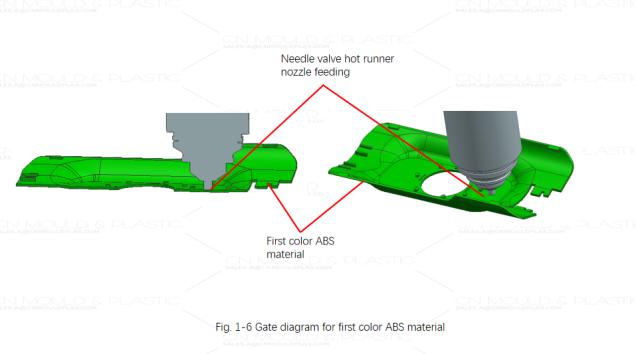

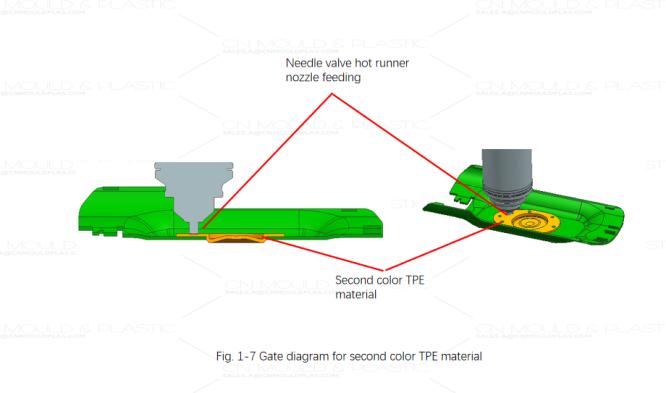

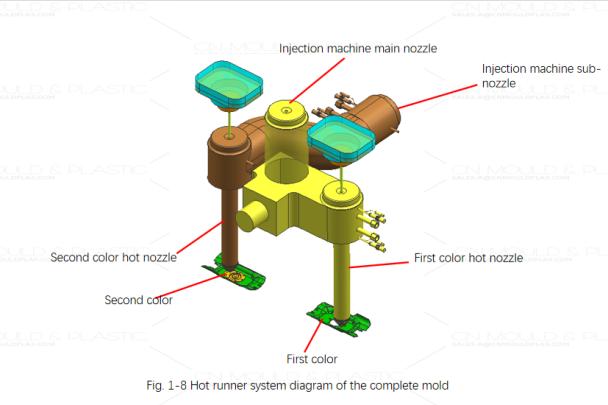

Given the product's small size, needle valve hot runner nozzles are used for both the first and second color materials to enable automated injection molding production. Figure 1-6 shows the gate design for the first color (ABS material). Figure 1-7 shows the gate design for the second color (TPE material). Figure 1-8 presents the complete hot runner system diagram for the entire mold.

For the two-color molded products No. ① and No. ② within this three-color set, the second color can be entirely formed within the cavity of the fixed mold half. This aligns with the basic principle of standard two-color mold design: differing shapes in the fixed mold, identical shapes in the moving mold. The distinctive feature of this two-color mold design lies in integrating two-color injection molding and overmolding within a single mold set, thereby achieving a three-color product from a two-color molding process.

First, based on the above analysis, the parting line between the fixed and moving mold halves for the two-color product is determined. This two-color product has an undercut in the fixed mold half, necessitating an ejection mechanism on the fixed mold side to ensure the first color product remains on the moving mold core. Since this is a two-color mold, the final product must be ejected from the moving mold half. Therefore, this two-color mold set requires ejection structures on both the moving and fixed mold halves.

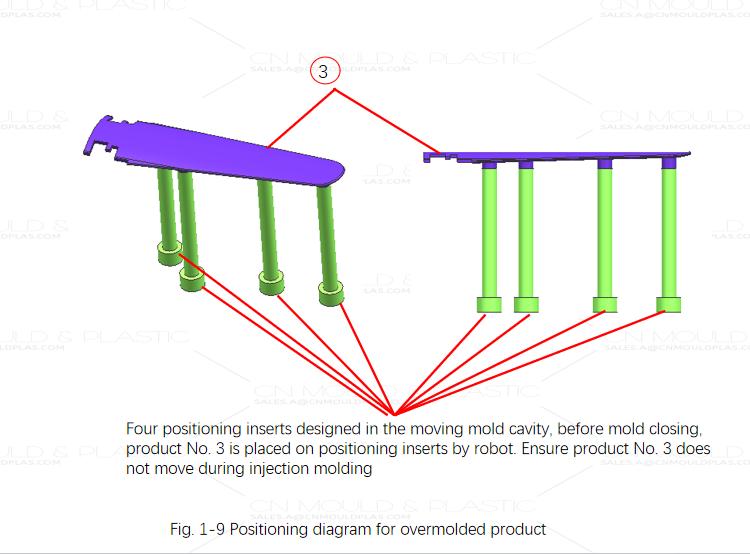

Secondly, before mold closing and injection molding commence for the two-color process, a positioning device for product No. ③ must be designed within the moving mold cavity. This secures product No. ③, preventing its movement during mold closing and injection. Figure 1-9 shows the positioning diagram for product No. ③, which requires overmolding

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk