Product Ejection

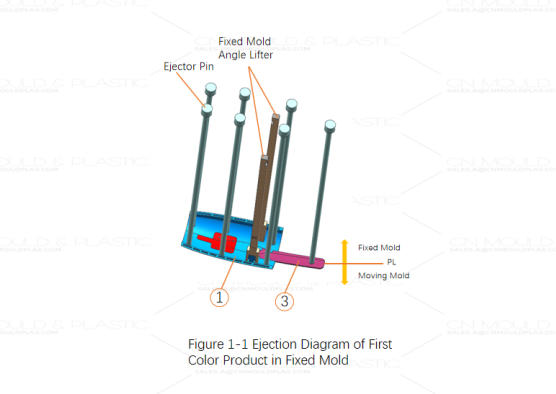

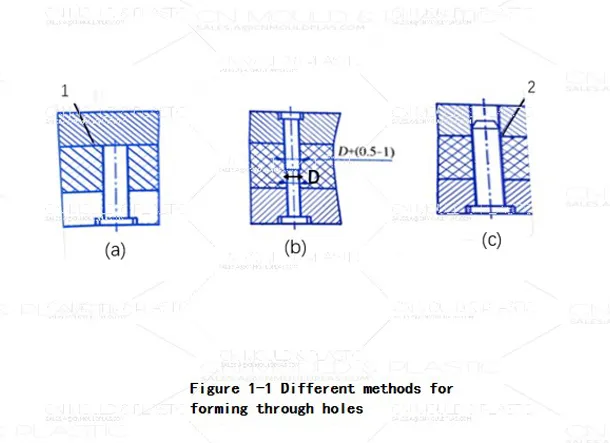

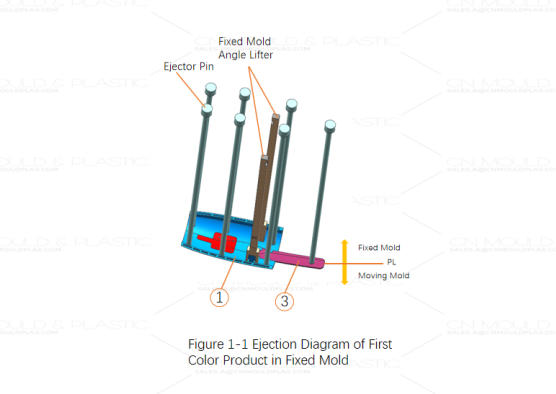

The ejection structure of this mold, although not overly complex, consists of three parts: the first-color cavity plate ejection, the second-color cavity plate ejection, and the moving plate ejection. After the mold completes the injection molding of the first color (ABS material), during the first mold opening, the spring installed in the first-color cavity ejector plate acts together with the ejector plate, ejector pins, and angled lifters to eject the first-color product, leaving it in the moving mold cavity, as shown in Fig. 1-1.

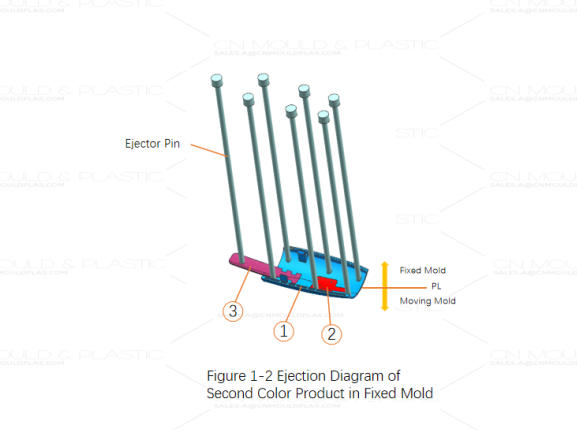

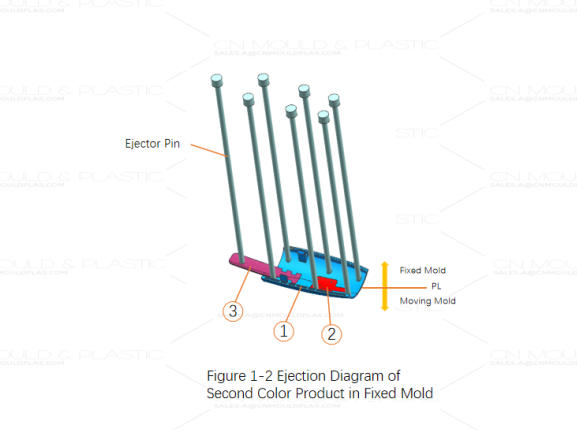

After the mold fully opens, the rotary table of the injection molding machine rotates 180°, followed by the injection molding of the second color (TPU material). Upon completion of the second injection, the mold undergoes its second opening. Simultaneously, the spring installed in the cavity ejector plate acts together with the ejector plate and ejector pins to eject the product, leaving it in the moving mold cavity, as shown in Fig. 1-2.

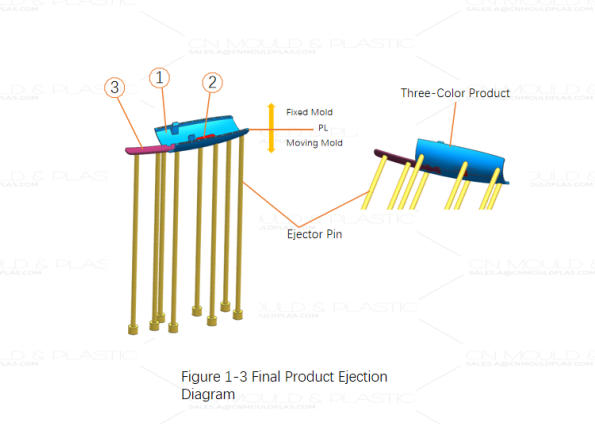

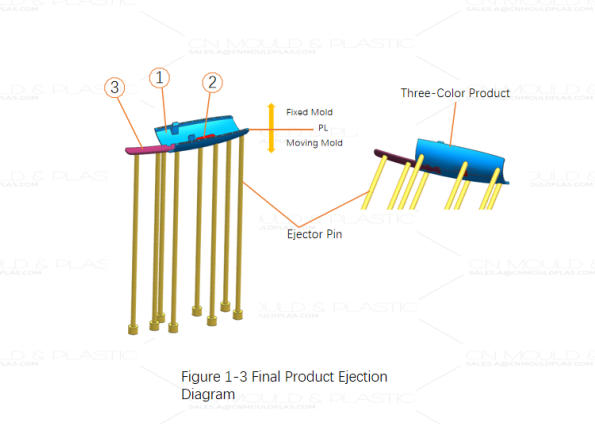

After the second mold opening is complete, the final three-color product remains on the moving mold core. Due to the low holding force on this product, direct ejection using ejector pins on the moving side is sufficient, as shown in Fig. 1-3.

Injection Process Analysis

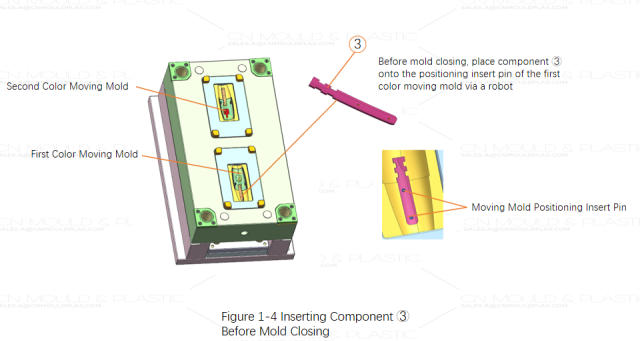

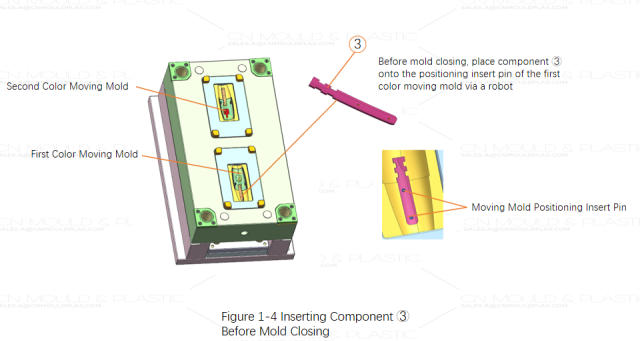

Before mold injection begins, the robot places the No.③ product onto the positioning pins of the first-color moving mold core, as shown in Fig. 1-4. The mold then closes for the first-color material injection molding. After the first-color injection is complete and following the first mold opening, the moving platen rotary table rotates 180°, moving the first-color moving mold core and the first-color product to the second-color injection position.

The mold closes again for the second-color material injection molding. After the second injection molding is complete and following the second mold opening, the final product is ejected from the moving side, completing the molding cycle for one full three-color product.

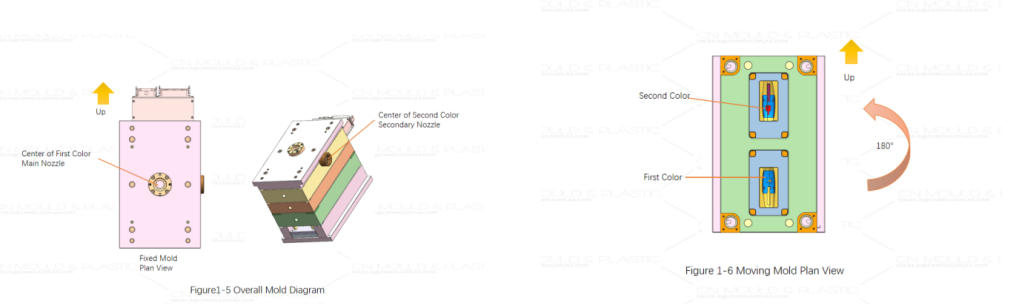

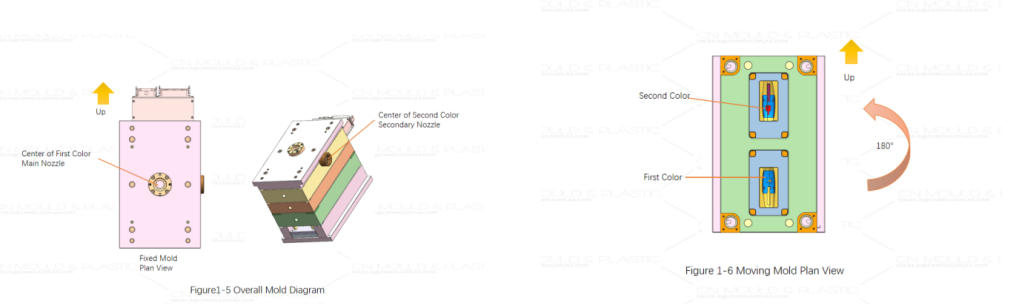

During actual production, the first-color and second-color products are injection molded simultaneously. In each molding cycle, the mold opens once, the injection molding machine's rotary table rotates once, and one two-color product and one complete three-color product are produced. Figure 1-5 shows an overall view of the mold set, and Figure 1-6 shows the plan view of the moving half.

Points for Attention

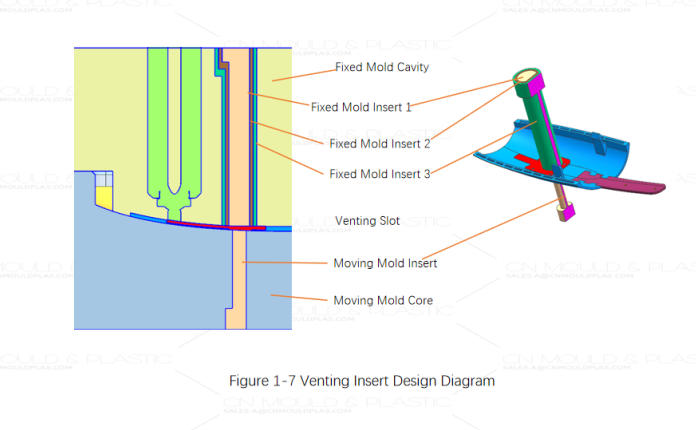

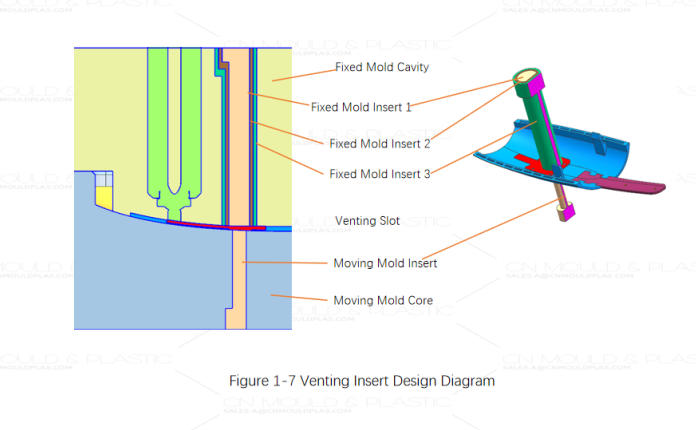

The second color of this product has high cosmetic requirements, and the second-color material is prone to air trapping. Therefore, inserts are designed in the cavity plate. All inserts are designed and machined with venting slots, as shown in Fig. 1-7.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk