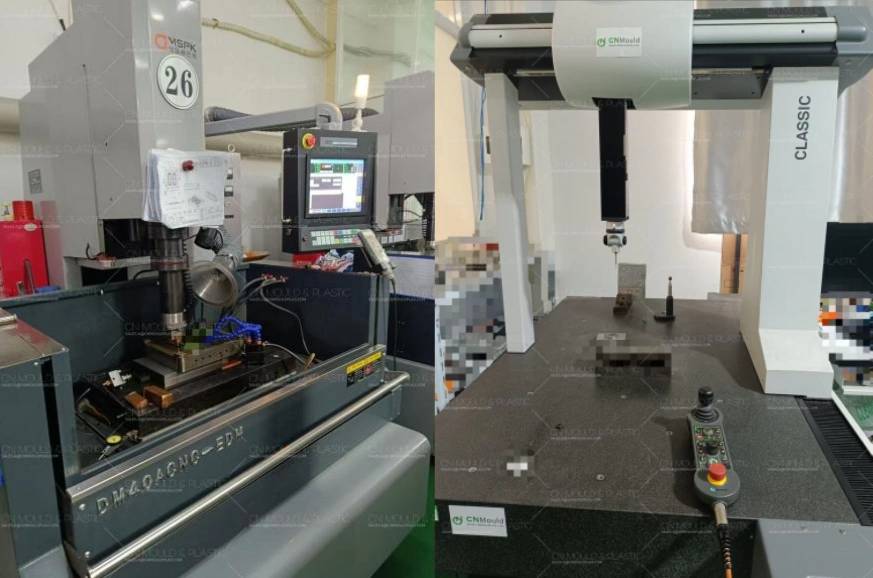

Product Ejection

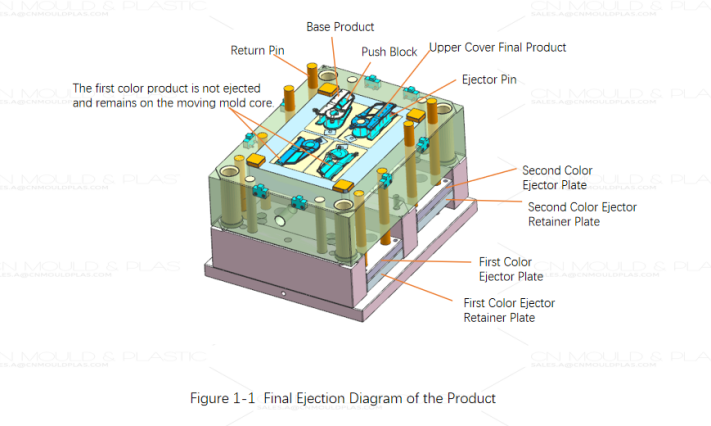

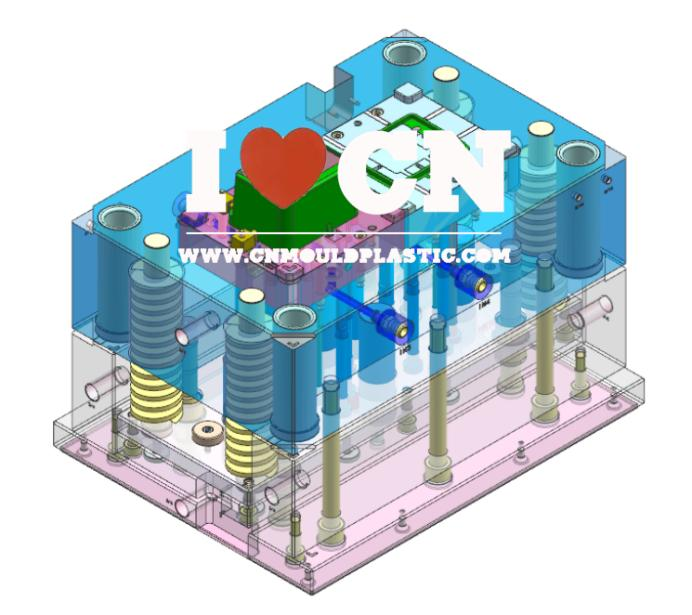

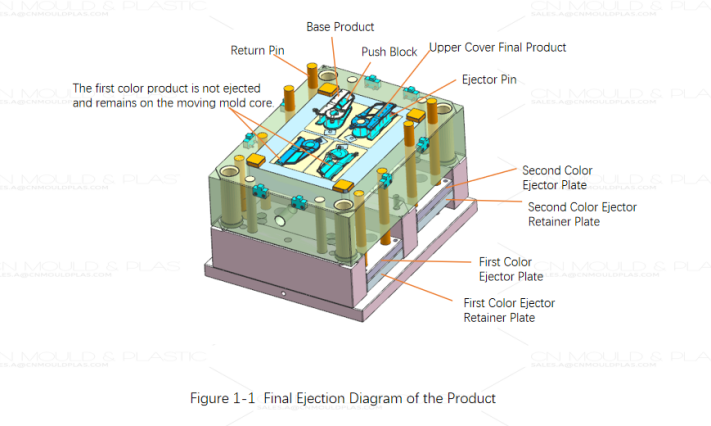

This mold is a typical two-color mold with a rotating moving half. After the first color product is injection molded, the mold opens for the first time. The moving half then rotates 180 degrees to reach the injection position for the second color product. Following the completion of the second color injection molding, the mold opens for the second time, and the product is ejected at the second color station. This mold set uses standard ejector pins and push blocks for product ejection. Figure 1-1 shows the final ejection diagram of the product.

The fixed mold cavity of this mold is made of P20 steel with an as-delivered hardness of 32-35 HRC, and undergoes surface nitriding treatment to achieve a hardness of 650-700 HV. The moving mold core is also made of P20 steel (32-35 HRC as-delivered), with surface nitriding treatment (650-700 HV). The sliders are made of P20 steel (32-35 HRC as-delivered), with surface nitriding treatment (650-700 HV). Both the moving mold inserts are made of P20 steel (32-35 HRC as-delivered), with surface nitriding treatment (650-700 HV). The angular pin is made of P20 steel (32-35 HRC as-delivered), with surface nitriding treatment (650-700 HV).

Injection Process Analysis

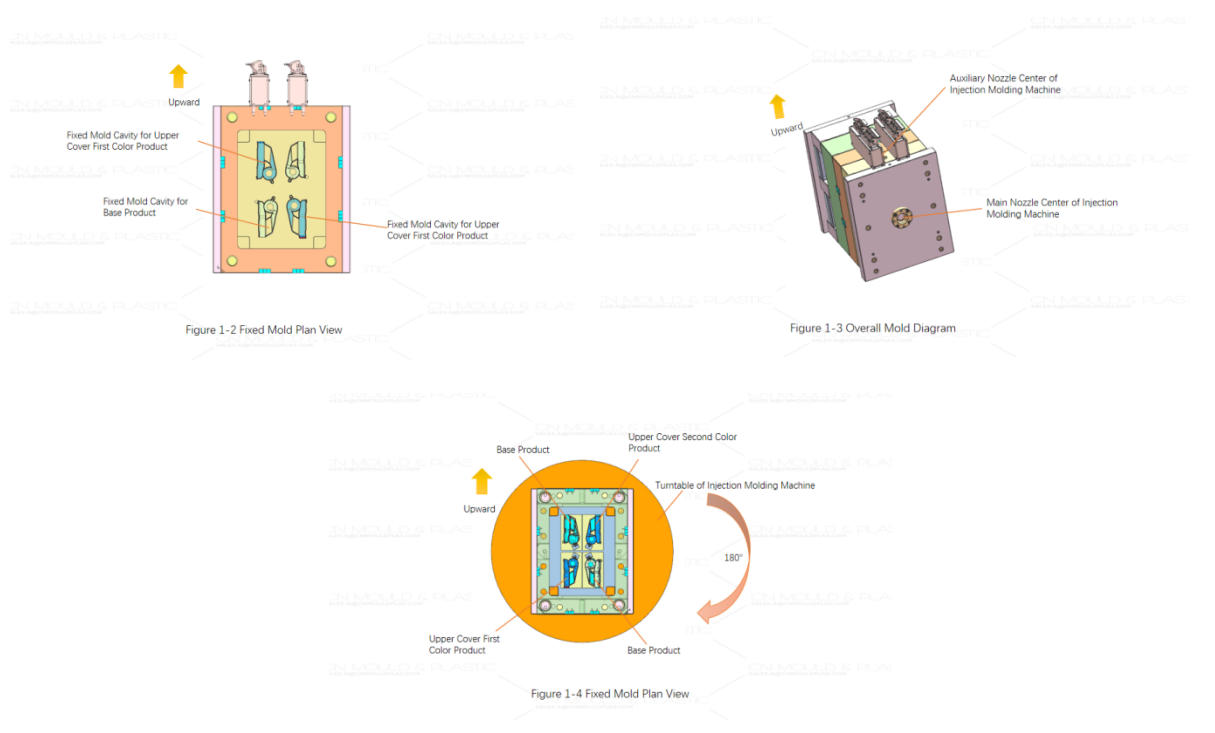

After the first color product is molded, the mold opens for the first time. Subsequently, the moving half rotates 180 degrees, and the mold closes again for the second time to complete the injection molding of the second color product. Once both injection molding stages are finished, the mold opens again. The injection machine's ejector bar then pushes the ejector plate and retainer plate, which in turn drive the ejector pins and push blocks to eject the product at the second color station, completing the molding cycle for a full two-color product.

In actual production, the injection molding of the first color product and the second color product occurs synchronously. This means each molding cycle produces one complete two-color upper cover product and one single-color base product.

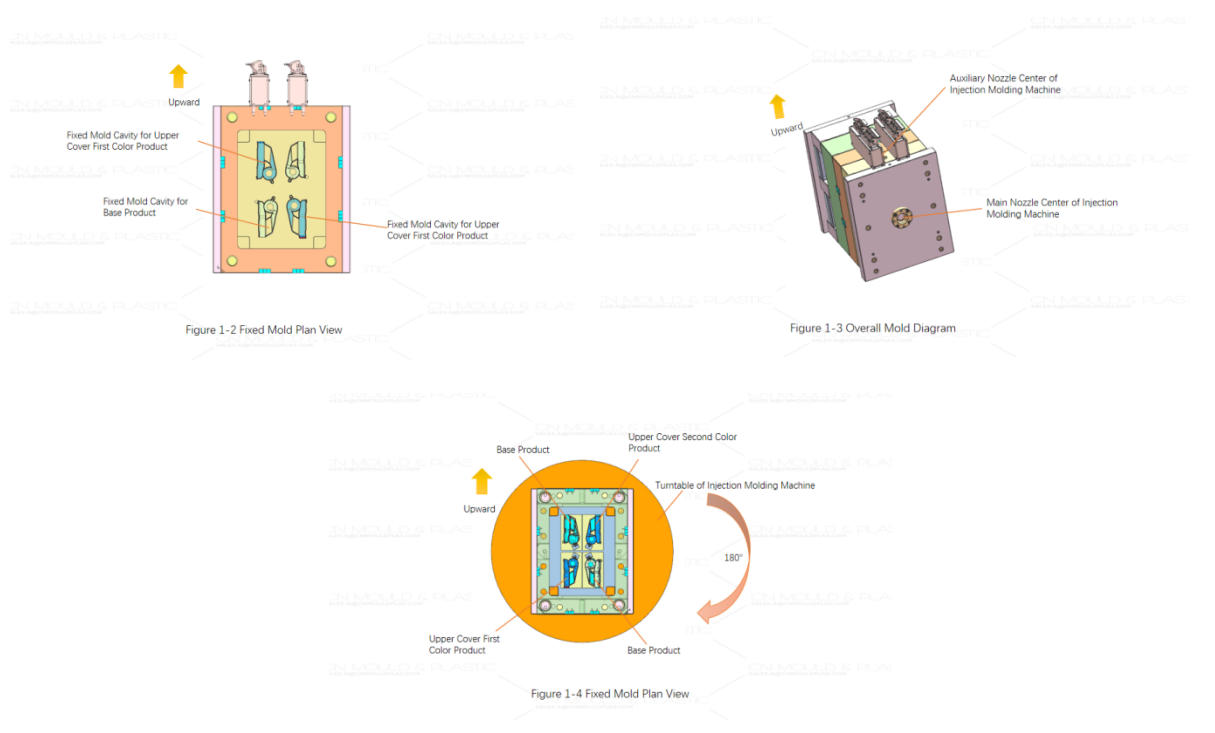

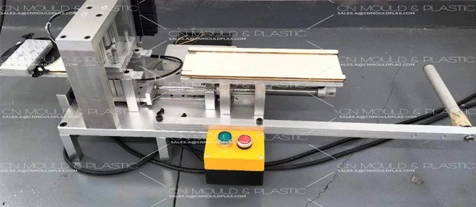

Figures 1-2 to 1-4 respectively show the fixed mold plan view, the overall mold diagram, and the moving mold plan view.

Precautions

Before designing the mold, conduct a thorough analysis of the product. Pay special attention to features that will be formed by the second color material, ensuring they are located at the same position on the product. Different mold structures may be required for the first color and second color at the same location.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk