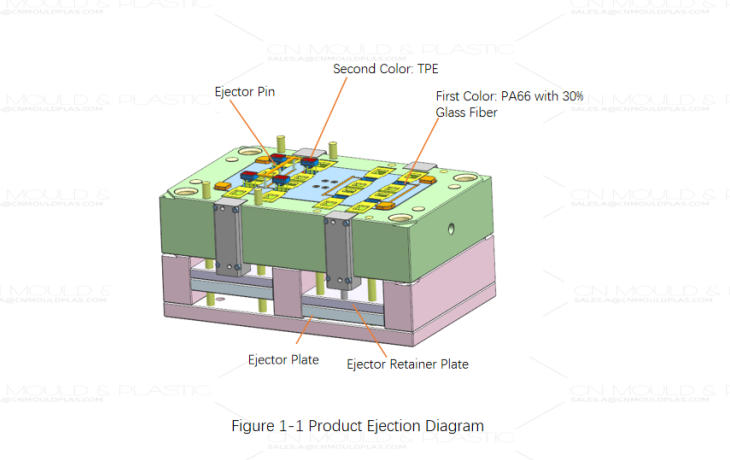

The ejection of this two-color product is relatively straightforward. The ejector rod of the injection molding machine pushes the ejector plate and the ejector retainer plate, which in turn drive the ejector pins mounted on the ejector plate to directly eject the product, as shown in Figure 1-1.

This mold set showcases the application of a seesaw mechanism to achieve two-color injection molding. This design is a typical case study in simplifying mold structure and reducing manufacturing costs. During actual production, within each molding cycle, the first-color product and the second-color product are molded simultaneously, resulting in 4 first-color products and 4 complete two-color products per cycle.

After each mold opening, the ejector rod of the injection molding machine at the second-color station pushes the ejector plate, ejector retainer plate, and ejector pins at that station to eject the second-color product along with the cold runner. Subsequently, the moving platen rotates, carrying the movable mold half to the next working position. The machine then closes the mold for the next injection cycle, enabling continuous production.

In this mold, the molding inserts are not housed within the mold plates. Instead, they are positioned using locating inserts and are secured from the molding surface to the mold frame with screws. The fixing method for the cavity insert in the stationary side is similar. We refer to this structural design for securing molding inserts as a "Hamburger" structure. This structure simplifies the mold, facilitates machining and maintenance of mold components, and is suitable for molds with relatively small parting surface steps and smaller part dimensions.

Since the second-color part of the product has numerous small holes, the corresponding movable mold half contains a relatively high number of sliding inserts. To ensure smooth mold action, multiple seesaw mechanisms and knock-out pins/strikers need to be designed. Additionally, multiple springs are installed inside the mold to ensure the sliding inserts move to their respective working positions reliably.

Due to the product's small size, the gating for both the first and second colors is achieved via hot nozzles transferring to cold runners. The cold runners for the first-color product and the second-color product are designed as trapezoidal runners. The cold runner of the first-color product is utilized to form the cavity for the second-color product's runner, thereby saving design space.