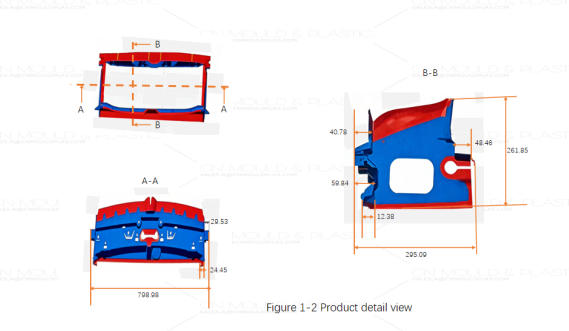

Figure 1-1 presents a two-color drawing of an automotive interior component, where the green section is the first-shot PP+30% GF material (hard plastic) and the orange section is the second-shot TPE material (soft plastic). Due to its considerable size, this product requires a large-scale two-color mold.

The product features an average wall thickness of 2 mm and overall dimensions of 798.98 mm × 295.09 mm × 261.85 mm. The first-shot PP+30% GF material weighs 539.73 g, while the second-shot TPE material weighs 274.75 g. The mold is designed for a 1+1 cavity layout: the hard plastic is molded first, followed by overmolding the soft plastic onto the hard plastic substrate.

As illustrated in Figure 1-2, both the PP+30% GF and TPE sections have peripheral undercuts, resulting in a complex structure. Evidently, this product does not comply with the fundamental principle for simple two-color mold design—distinct cavity-side profiles with identical core-side configurations. Consequently, it cannot be manufactured using a conventional rotating-core two-color mold. Moreover, its large size would necessitate a two-color injection molding machine with a clamping force exceeding 3,500 tons if equipped with a standard rotating-core turntable, leading to prohibitive molding costs.

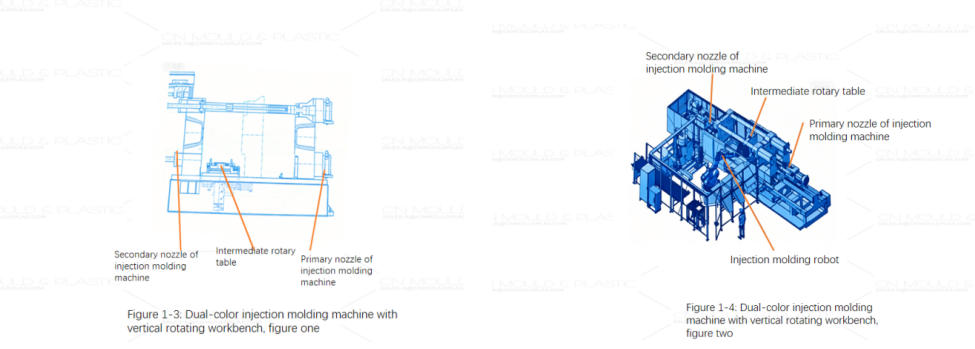

Figures 1-3 and 1-4 depict the final two-color injection molding machine selected for this mold—a balanced model integrated with a central vertical rotating table. The main nozzle is installed at the standard position, with the secondary nozzle opposite to it. Positioned between the two nozzles, the rotating table enables 180° vertical rotation. This configuration reduces the required machine clamping force to 1,700 tons, though its mold clamping thickness is double that of a standard injection molding machine.