PQC Inspection Process

(1) When there's a mold change or shift change in production, PQC conducts the first article inspection. If it passes, production continues; if not, adjustments are made before resuming.

(2) PQC carries out patrol inspections on products during production according to product categories.

(3) If the patrol inspection passes, production keeps going. If there's an abnormality, a non-conformance report is filled out, and the process staff will call relevant department personnel for an MRB meeting.

(4) If the MRB meeting resolves the abnormal issue, production resumes; otherwise, they keep working until a solution is found.

PQC Control Measures

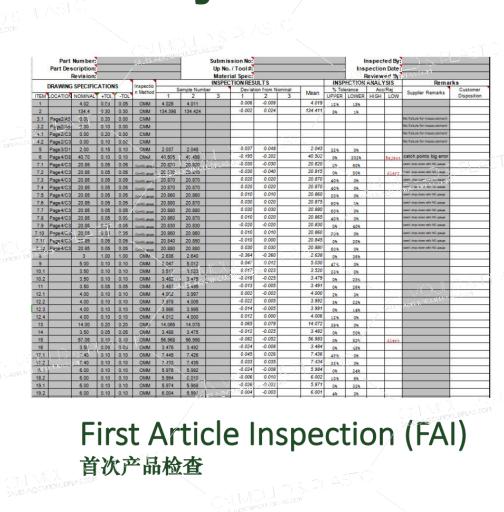

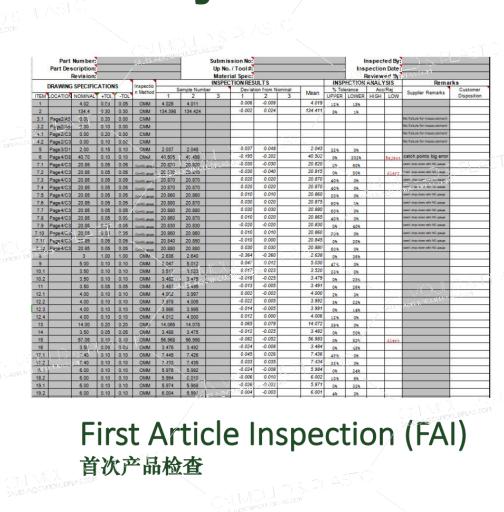

1. First Article Inspection

When there's a new mold change, mold repair, restart after a shutdown, or material replacement, PQC needs to finish the first article inspection within 30 minutes after the process staff have set up the product properly. The inspection results are filled in the test record sheet, and the records are kept. The first article is placed in a designated location. The first article after a mold change is kept until the next mold change. The first article of a shift is kept until the end of that shift and is automatically discarded once the first article of the next shift is produced.

The production workshop acts based on PQC's judgment: if the product passes inspection, production continues; if there are minor defects, inform the process staff to adjust the machine and rectify before production;for serious defects, stop production immediately and notify the technical, quality, and relevant departments (such as production planners in the business department) for a review meeting.

2. In-Process Inspection

PQC staff conduct patrol inspections during production according to inspection documents (SIP), drawings, first article of startup, and other relevant standards. For appearance inspection, it's 8-10 pieces every 90 minutes for Class A and B products, and 8-10 pieces every 120 minutes for Class C products. The inspection cycle and sampling quantity for functionality, assembly, reliability, and dimension checks are based on the inspection documents (SIP). The inspection results are recorded in the "PQC Inspection Report". The inspection frequency can be adjusted by each injection molding factory according to its own product characteristics.

3. Handling of In-Process Abnormalities

For major defects (MA) of products and problems in the production process, PQC staff fill out a non-conformance report. After confirmation by the workshop foreman, relevant personnel such as workshop technicians and production planners are called to analyze and propose improvement measures. PQC verifies the effectiveness of the improvement measures proposed by the responsible unit. If ineffective, PQC returns the measures to the original responsible unit to propose new ones.

If PQC continuously finds more than 5 similar major defects (MA), the process defect rate is too high (exceeding 15% when calculated based on hourly output), there are batch defects, or problems that seriously affect product reliability, PQC fills out a non-conformance report and reports to the production process staff. The process staff then presides over an MRB meeting to handle the issue.

4. Handling of Non-Conforming Products

When PQC finds non-conforming products during production, they should stamp a red "Non-Conforming Product" seal on the product identification form. After confirmation by the team supervisor, the supervisor arranges for staff to place the defective products in the defective product area for isolation and control. The handling of non-conforming products is based on the conclusions of the MRB meeting.

Main Work Content and Notes for PQC

(1) Conduct first article inspections in a timely manner (after mold setup is qualified or after shift handover), including the first article at startup and the first article of the shift.

(2) Timely feedback information about unqualified first article inspections to process staff and team management, and issue a "Non-Conformance Report" if necessary.

(3) When conducting first article inspections, must clearly inform workers of the self-inspection requirements for product quality, and mark some key quality characteristics and control points on the product.

(4) Conduct patrol inspections as required: the patrol cycle for key products (such as Class A and B products) is 90 minutes, and for Class C products, it's 120 minutes.

(5) The sampling quantity for patrol inspections is 8-10 pieces (5-6 molds if there are multiple cavities in one mold) per inspection frequency.

(6) During patrol inspections, carefully and earnestly compare with samples (first article at startup, first article of the shift).

(7) During patrol inspections, strictly follow the provisions of inspection documents for sampling, sample submission, and inspection of dimensions, color difference, and assembly (usually 2-3 molds per frequency within 2 hours).

(8) If during patrol inspections, it's found that non-conformities are caused by improper working methods of workers, correct the workers immediately. If there's no improvement, feedback to the operator's superior supervisor, and mark and isolate the produced non-conforming products.

(9) If during patrol inspections, non-conformities are caused by production process issues, timely feedback to the on-duty process staff and team leader, request improvement, and track the handling of the matter. Dispose of and isolate the produced non-conforming products. If the problem isn't solved, timely feedback to the superior supervisor, who will organize further solutions according to procedures.

(10) For serious defects with a batch quantity exceeding the 2-hour output, issue a "Non-Conformance Report" and submit it to relevant responsible departments for rectification.

(11) For quality issues that can't be judged, feedback to the inspection supervisor, and must clearly describe the problem points when giving feedback.

(12) PQC must fill out inspection record forms in a timely manner as required, especially ensuring that the recorded inspection data is true and reliable. All records must have the inspector's handwritten signature and date; otherwise, they are deemed invalid.

(13) PQC should timely communicate information about defective quality found during patrol inspections with FQC.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk