Designing a mold for a complex overmolded part is always a challenge, but some projects truly push the boundaries. This blog walks through the critical thinking and solutions for a particularly intricate component: a part requiring a rigid PP with 30% glass fiber substrate fully interlocked with a soft TPE overmold on all four sides. The complexity demanded innovative solutions for both part ejection and gate design.

The part's geometry presented an immediate hurdle: it had undercuts on all four sides. Furthermore, the second-shot TPE was intricately intertwined with the first-shot rigid PP, making a simple rotating mold or side-action on the moving half insufficient. A conventional approach would not work.

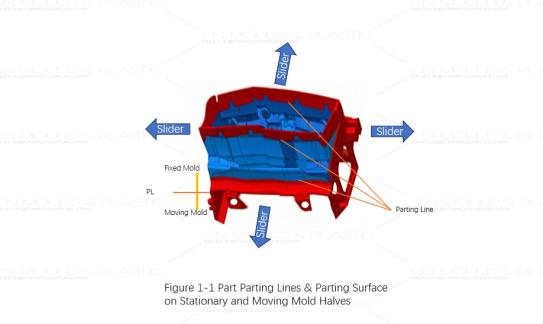

The Solution: Stationary Mold (A-Side) Sliders.

To successfully form this complex interlaced structure, we utilized a network of sliders built into the stationary mold half. This strategy allows for creating the necessary undercuts and intricate interfaces between the two materials. Once the TPE shot cools, the mold opens, and the stationary-side sliders retract first, freeing the undercuts. The part can then be cleanly ejected from the moving (B-side) core. Figure 1-1 illustrates the resulting parting lines and surfaces for both mold halves, a map of the solution to this geometric puzzle.

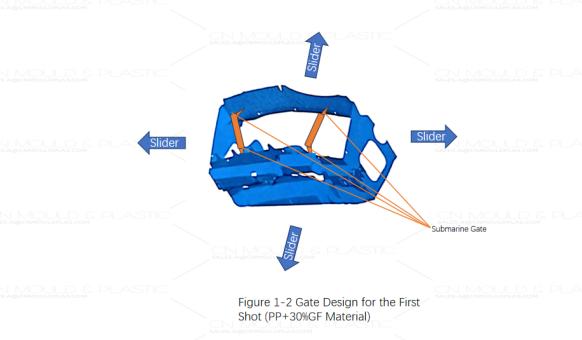

With the ejection strategy defined, the next focus was ensuring optimal material flow. For the first shot—the rigid, glass-filled PP—we analyzed the best gate locations and type.

Chosen Strategy: Hot Runner to 4-Point Submarine Gates.

Based on the part's features and size, the selected solution was a hot runner system feeding four strategically placed submarine (or "tunnel") gates. This approach, shown in Figure 1-2, offers several benefits: it allows gates to be placed in optimal locations for balanced filling, provides a clean, automatic gate break on ejection, and is well-suited for rigid materials.

Validation Through Mold Flow Analysis (MFA)

To ensure this design was sound, our mold flow engineer was involved from the early stages. A detailed simulation was conducted, yielding promising results:

Fill Time: 2.788 seconds – indicating efficient flow.

Injection Pressure: 138 MPa (max).

Holding Pressure: 110.4 MPa.

Pressure Drop in Runner System: 21.8 MPa (138 - 116.2 MPa), which is within an acceptable range for this material.

Required Clamping Force: 924.4 Tons, well within the capacity of our target 1700-ton injection molding machine.

Conclusion: The MFA data confirmed that the hot-runner-to-4-point-submarine-gate design for the first shot was not only feasible but optimal, ensuring complete filling without excessive pressure or clamp force.

The second shot presented its own unique challenge. The TPE needed to flow into and around the already-molded PP skeleton. The gate design for the overmold is just as critical as for the substrate.

Designing for Encapsulation Flow

During the part design phase, specific "flow channels" or pathways were incorporated into the first-shot PP geometry. These act as intentional runners, guiding the TPE to key areas and ensuring complete encapsulation of the intended features.

Given the part's size and complexity, relying on a single gate was not an option. Therefore, we employed a multi-point gating system for the TPE. This strategy ensures:

Balanced Filling: The viscous TPE reaches all interlocking features simultaneously.

Reduced Flow Length: Prevents premature cooling and hesitation lines.

Lower Required Pressure: Helps in molding the soft material over the existing rigid structure.

By combining pre-designed flow channels in the first shot with a well-planned multi-gate system for the second shot, we create a reliable path for the TPE to form its complex, interlocked geometry consistently and completely.