In plastic injection molding, the temperature of the mold is a critical factor that significantly influences the final quality of the manufactured part. Different plastic materials have varying requirements for mold temperature during the forming process. Understanding and controlling this parameter is essential for achieving optimal results.

Why Mold Temperature Varies by Material

Typically, for most common thermoplastics, the ideal mold temperature range falls between 40°C and 60°C. However, some engineering plastics require higher temperatures, from 110°C to 150°C, while certain specialty plastics may even demand temperatures as high as 230°C to 260°C. These differences stem from the unique crystallization characteristics and flow properties of each polymer. Consequently, an effective temperature regulation system must be capable of both cooling and heating the mold to maintain the specific range required for the material being processed.

During the injection cycle, the mold temperature is not static. It starts lower and gradually increases as the hot molten plastic enters the cavity. Furthermore, due to variations in part and mold geometry, temperature distribution across the mold surface is often uneven during the cooling and solidification phase.

How Mold Temperature Directly Affects Product Quality

Mold temperature exerts a direct influence on several key aspects of the molding process:

Flow and Filling: It affects the viscosity and flowability of the molten plastic.

Solidification and Shrinkage: It controls the rate of cooling, crystallization (for semi-crystalline materials), and ultimately, the part's shrinkage behavior.

Ease of Filling: It impacts how completely and easily the mold cavity is filled.

These factors collectively determine the final part's:

Dimensional accuracy and stability

Surface gloss and appearance

Internal stress levels

Mechanical properties

Overall production cycle time

Therefore, precise and consistent control of mold temperature is fundamental to stabilizing the molding process, enhancing product quality, and boosting productivity.

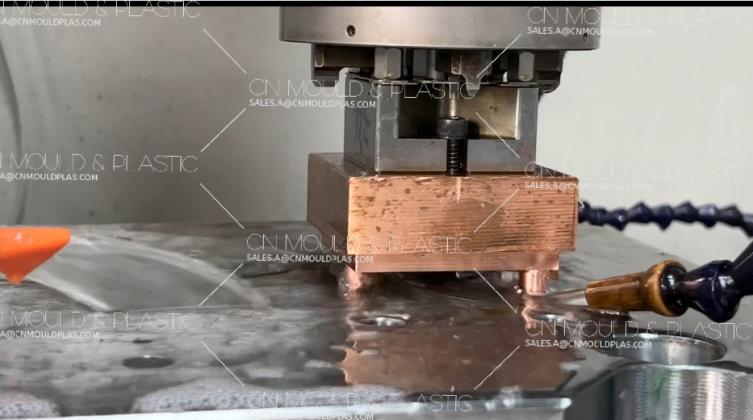

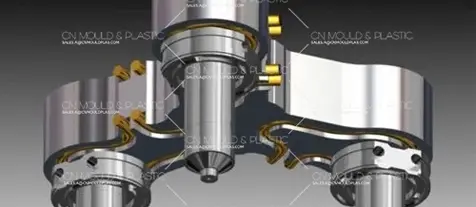

The Role of Temperature Control Systems

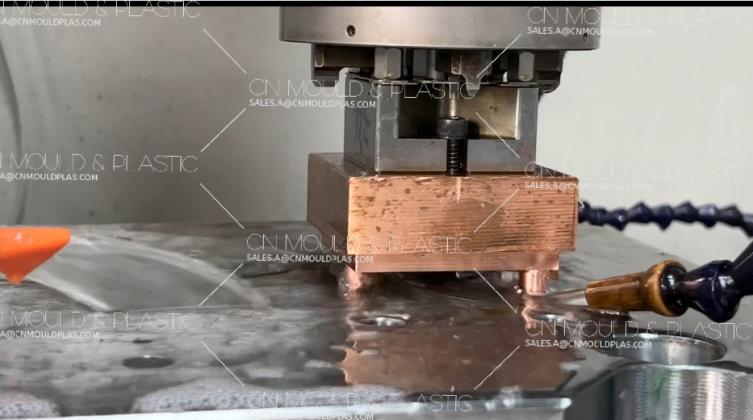

A robust mold temperature control system is designed to maintain the core and cavity within the prescribed temperature window. This is primarily achieved through cooling channels that remove the accumulated heat from the molten plastic. For most injection molding operations, cooling is the dominant requirement. The cooling system must be efficient enough to extract a specified amount of heat within a set time, ensuring each cavity remains stable at the target temperature.

Key Benefits of Proper Mold Temperature Control

1. Improved Flow & Dimensional Precision: Maintaining the correct mold temperature optimizes melt flow within the cavity, improving formability and reducing cycle times. Temperature that is too low can lead to poor flow, short shots, and increased residual stress, while excessively high temperatures risk material degradation. Most importantly, a constant and uniform mold temperature stabilizes the material's shrinkage rate—especially critical for crystalline plastics—directly enhancing dimensional accuracy.

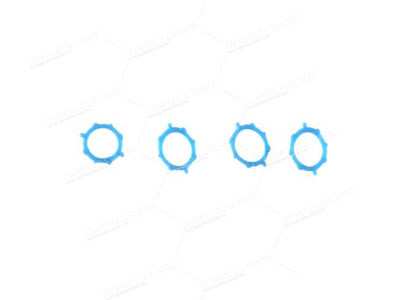

2. Stable Product Dimensions: As a direct result of controlled shrinkage, product dimensions become more consistent and predictable. This is particularly vital for parts with complex geometries, special structures, or non-uniform wall thicknesses.

3. Enhanced Appearance: An appropriate mold temperature significantly improves the surface finish of the molded part. It helps reduce defects such as flow marks, weld lines, sink marks, and sticking, leading to a superior gloss. For appearance-critical components like transparent parts or instrument panels, precise temperature control is non-negotiable.

4. Superior Mechanical Properties: Molding at a suitable and stable temperature allows the plastic to solidify under optimal conditions. This promotes uniform shrinkage, minimizes internal stress distribution, reduces warpage, and ultimately results in parts with excellent and reliable mechanical performance.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk