Machining on a Jig Grinder

Process Capabilities of Jig Grinders

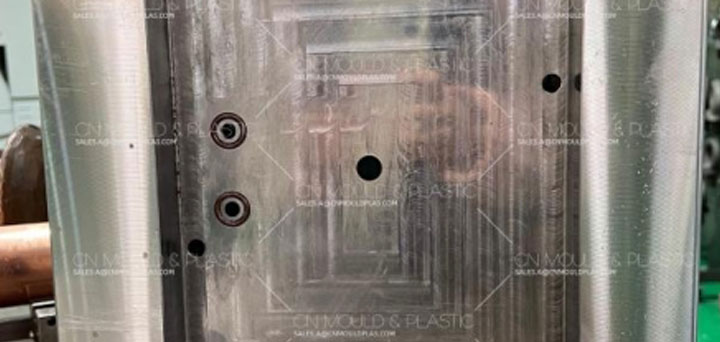

A jig grinder is an effective method for grinding precision components of stamping dies. It is primarily used for the fine machining of hardened parts. It can machine not only circular holes but also non-circular holes; not only internal formed surfaces but also external formed surfaces. Jig grinders have been widely adopted in mold manufacturing plants. Jig grinders are categorized into vertical and horizontal types.

Workpiece Setup

During grinding, the workpiece is typically positioned using two perpendicular datum surfaces on its exterior. Dial indicators are used to align these datum surfaces parallel to the longitudinal and transverse coordinates of the machine table. For convenience, a rotary table is often installed on the machine table to adjust the correct orientation of the workpiece datums. When clamping the workpiece, note that there are no significant cutting forces during coordinate grinding. Therefore, clamps only need to be tight enough to prevent the workpiece from moving. Attention should also be paid to the following:

(1) The workpiece should be set up high enough above the machine table to allow measurement of the bore diameter from both the top and bottom.

(2) When adjusting the workpiece position, prioritize the location of small holes first, as they are more difficult to align and typically have less grinding allowance.

Grinding Methods

(1) Internal Bore Grinding: Achieved by utilizing the grinding wheel's high-speed rotation, planetary motion, and axial reciprocating motion. Radial feed is accomplished by increasing the diameter of the planetary motion to enlarge the bore.

(2) External Cylindrical Grinding: Also achieved using the wheel's high-speed rotation, planetary motion, and axial reciprocation. Radial feed is implemented by decreasing the diameter of the planetary motion.

(3) Surface Grinding: For surface grinding, the wheel only rotates on its axis without planetary motion, while the worktable provides the linear feed. This method is suitable for precision machining of planar contours.

(4) Tapered Bore Grinding: Requires a special mechanism for grinding tapers. The wheel is first dressed to the required taper angle. As the spindle quill descends, the eccentricity (orbital radius) of the wheel's planetary motion increases accordingly.

(5) Side Grinding: Side grinding requires a special slot grinding attachment. The attachment's spindle can be driven independently by an electric motor. The vertical movement of the wheel allows grinding of side slots in profiles, profile holes with sharp corners, square holes, etc.

(6) Counterbore Grinding: For counterbore grinding, the planetary motion diameter is set according to the required bore diameter, and the axial position is fixed. While the grinding wheel spindle rotates, it simultaneously performs a downward feed motion, using the bottom edge of the wheel for grinding.

(7) Profile Hole Grinding: By combining the fundamental grinding motions mentioned above, complex profile holes can be machined.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk