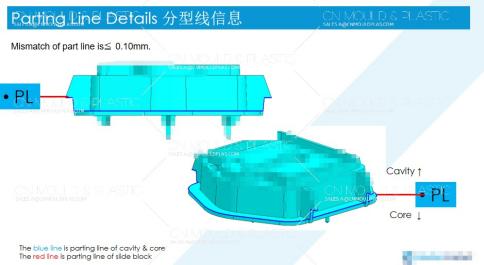

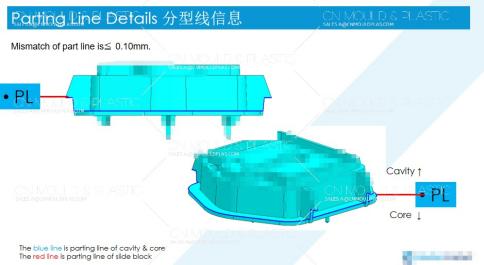

In injection mold design, the parting line (also called the parting surface) is one of the most fundamental and critical concepts. It refers to the interface where the two halves of the mold—usually the core and the cavity—meet and separate to allow the removal of the molded plastic part and the runner system.

While parting surfaces can be designed as flat planes, curved surfaces, or stepped surfaces, a simple flat plane is often preferred for ease of manufacturing, mold maintenance, and reliable part ejection. Complex parting surfaces are generally reserved for special part geometries or functional requirements.

Selecting the optimal parting line is typically the first step in the mold design process, as its location influences:

A well-chosen parting line ensures smoother mold operation, higher part quality, and longer mold life.

Key Principles for Parting Line Selection

1. Maximize Cross-Section

Place the parting line along the largest cross-section of the part to facilitate easy ejection.

2. Minimize Visible Flash

Position the parting line in less noticeable areas—such as edges or corners—where any resulting flash can be easily trimmed without affecting appearance.

3. Favor Moving Side Retention

Since ejection systems are usually on the moving half, design the parting line so the part stays on the moving side. Cores should generally be placed on the moving half to use the part’s shrinkage force for retention. If no core is present, the cavity itself should be on the moving side.

4. Preserve Dimensional Accuracy

Avoid splitting critical tolerance zones with the parting line, as mold misalignment can introduce dimensional variation.

5. Optimize Side-Action Direction

For side cores or lifters, the longer travel should align with the main mold opening direction, while shorter movements can be designed as side actions.

6. Consider Clamping Force Distribution

For large parts with significant projected area, keep the major parting plane perpendicular to the clamping force. Smaller side parting surfaces can be used for local undercuts.

7. Prefer Simplicity

Simple flat parting surfaces are easier to machine, maintain, and seal during injection.

8. Support Venting

When the parting surface also serves as a primary venting path, position it at the end of material flow to help air escape.

9. Facilitate Manufacturing and Ejection

For non-planar parting surfaces, ensure the geometry is both manufacturable and conducive to part release.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk