Product Description

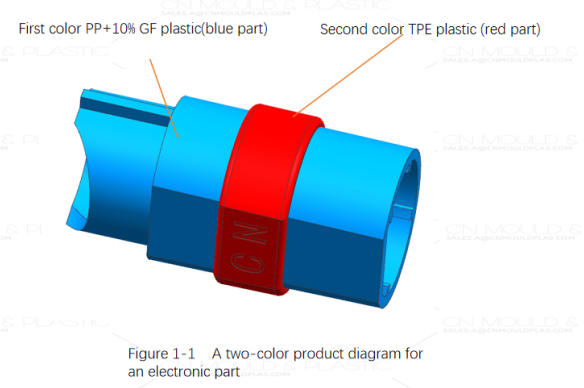

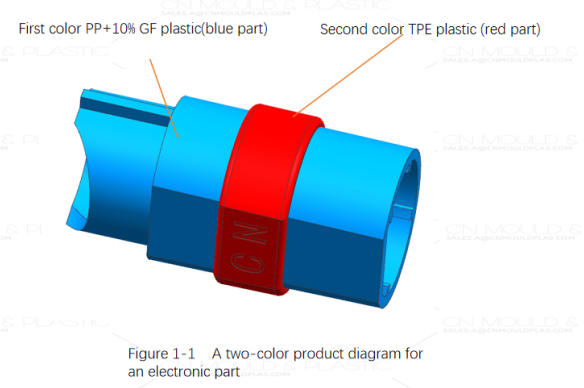

Figure 1-1 shows a two-shot product of an internal electronic component. It has an average wall thickness of 1.5 mm and overall dimensions of 31 mm × 42.7 mm × 131 mm. The green section represents the first material, PP+10% GF, with a weight of 52 g, while the orange section is the second material, TPE, weighing 9.5 g. Although structurally simple, the product has high aesthetic requirements, making it a typical precision two-shot injection-molded part produced using fixed-mold half blocks. The mold is designed to produce 4+4 cavities per cycle.

Design Highlights

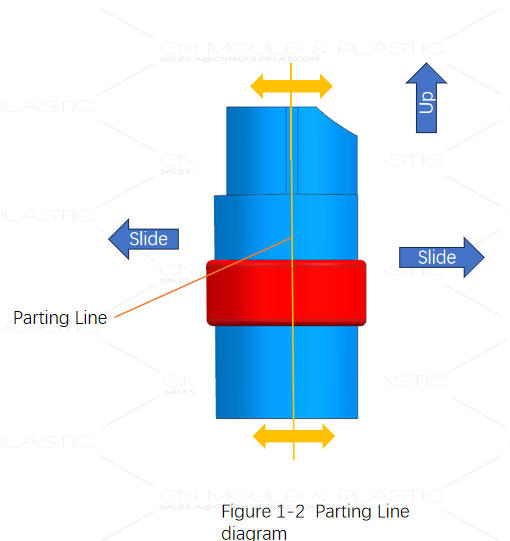

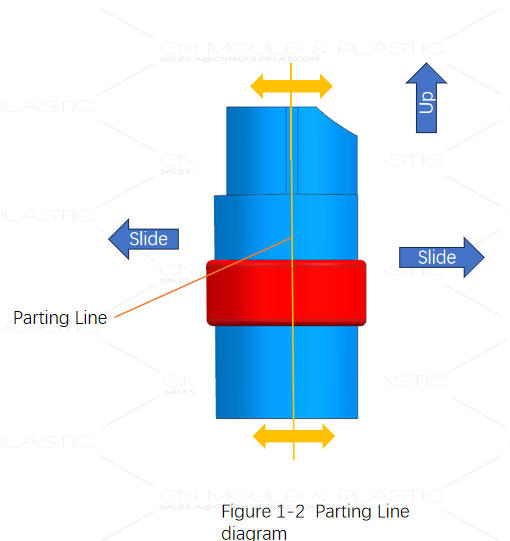

1.Parting Line and Ejection Direction

This is a slender part with high appearance standards. Based on its characteristics, conventional fixed-mold half blocks are used to form different material sections, enabling the injection of two different plastics. The parting line is relatively simple—split along the product’s maximum contour at the center, as shown in Figure 1-2.

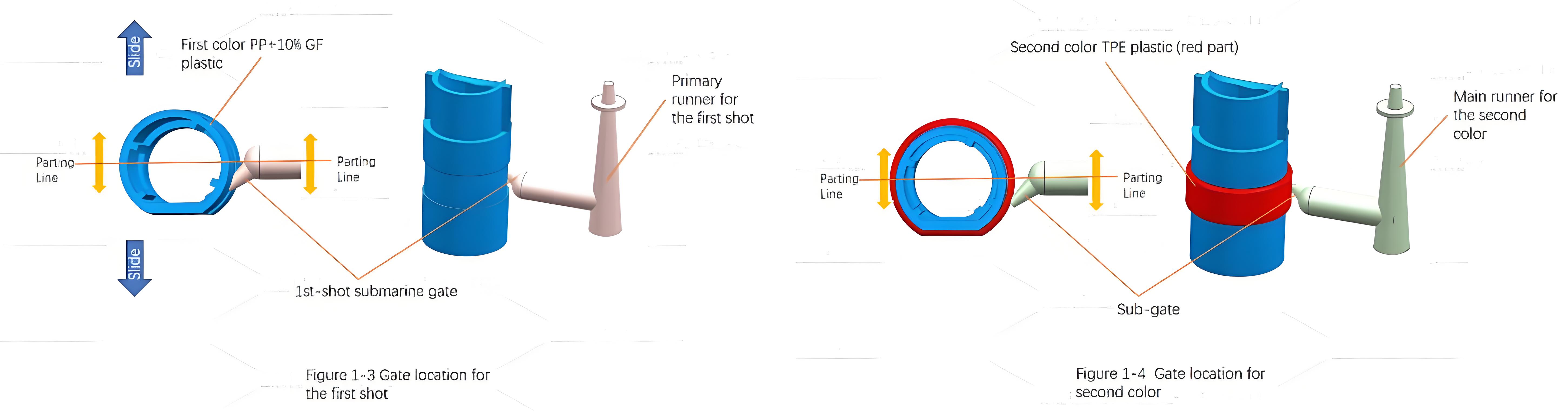

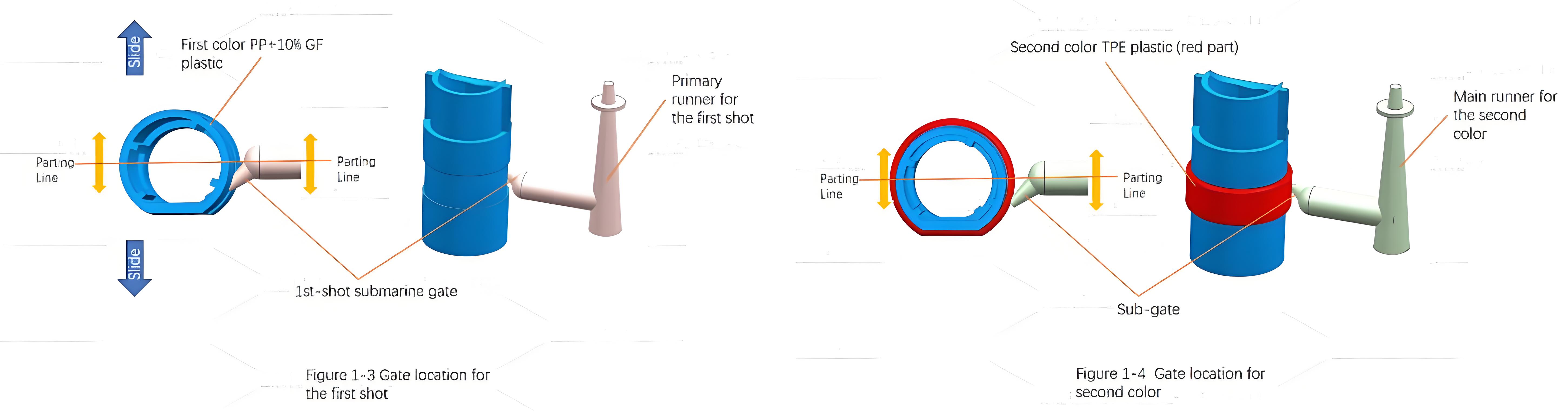

2.Gate Design

For molds with a half-block structure, gates for both the first and second materials can be designed at the slider parting line, using submarine gates to feed into the product surface. The gate for the first material can be placed where it will be fully covered by the second material, avoiding any impact on appearance, as shown in Figures 1-3 and 1-4.

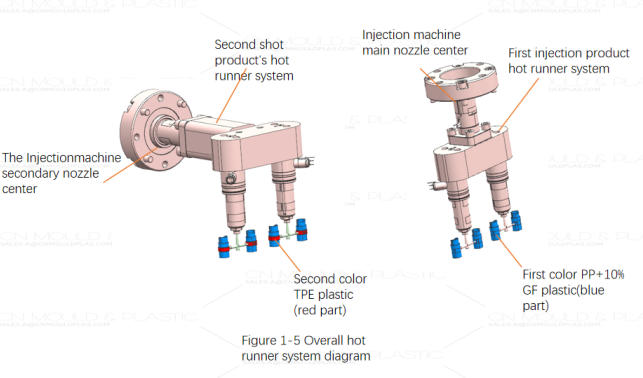

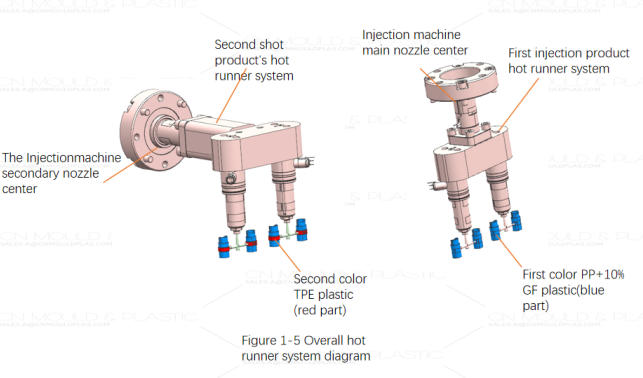

This mold is configured for an L-type two-shot injection molding machine. The primary nozzle is in the standard position, while the secondary nozzle is located opposite the operator. Due to the significant difference in material weights, the first material (PP+10% GF) is injected through the primary nozzle, and the second material (TPE), which requires a smaller shot volume, is injected through the secondary nozzle. A hot-runner-to-cold-runner gating system is used. Figure 1-5 shows the overall hot-runner system of the mold.

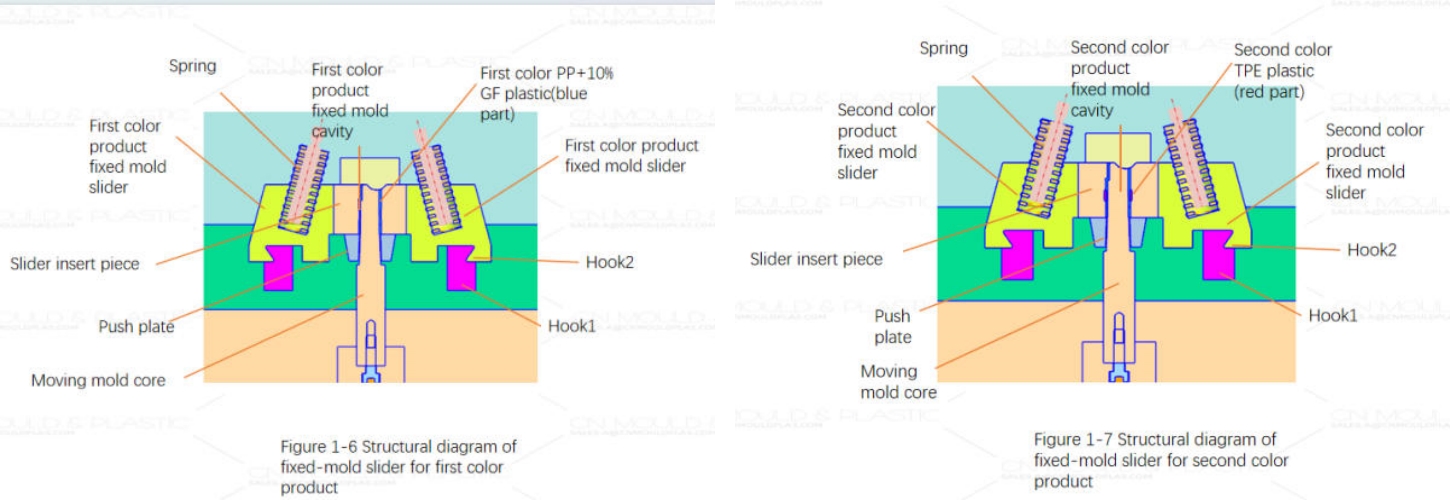

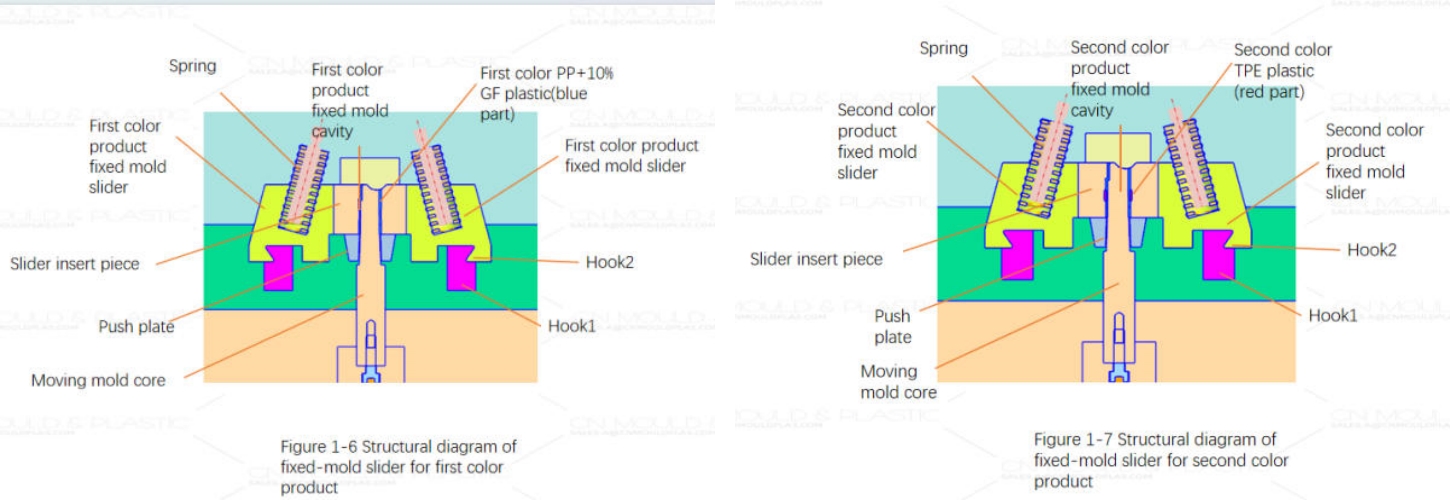

The design features of this mold represent a typical application of fixed-mold half blocks in two-shot molding. By altering the cavity shapes of the sliders at different positions in the fixed mold, two-shot injection molding is achieved. Note that this product does not follow the basic principle of simple two-shot mold design, where the fixed-mold cavities can differ but the moving-mold cavities must be identical. As mentioned in previous chapters, fixed-mold sliders can be used for two-shot molds where the second material cannot be fully accommodated in the fixed-mold cavity. Figures 1-6 and 1-7 show the main structure of the fixed-mold slider design. During mold opening, the fixed-mold slider is ejected via Hook 1, Hook 2, and springs to complete the core-pulling action. During mold closing, the slider is forcibly reset by the moving-mold ejector plate and hard strips.

3.Product Ejection

Before analyzing product ejection, it is essential to understand the mold structure. One key design challenge is that the cold runners for the first and second materials are located in the same position (see Figure 1-5). How is the second material injected?

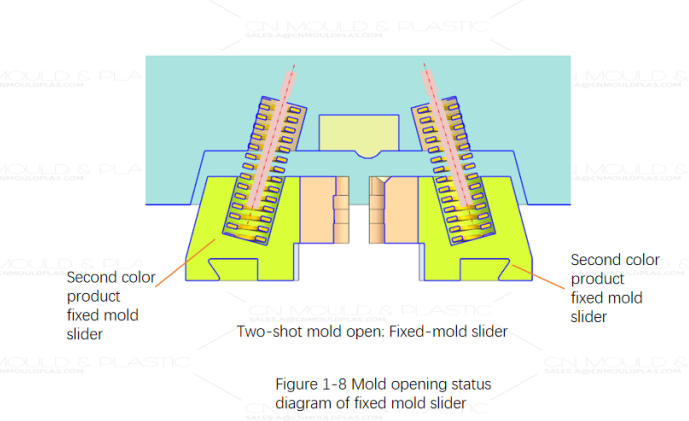

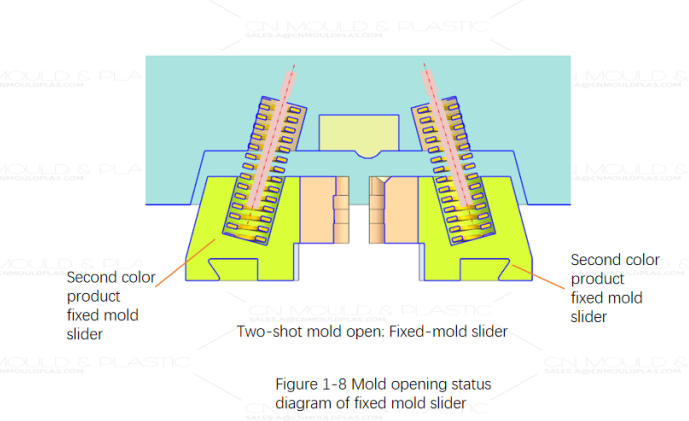

Typically, products molded with half-block structures are ejected using a moving-mold ejector plate. This mold, being a typical fixed-mold half-block structure, also meets the conditions for ejector plate ejection. As shown in Figure 1-7, after the second material is injected and molded, the fixed-mold slider completes the core-pulling action during mold opening with the combined action of Hook 1, Hook 2, and springs. Figure 1-8 shows the mold opening state of the fixed-mold slider.

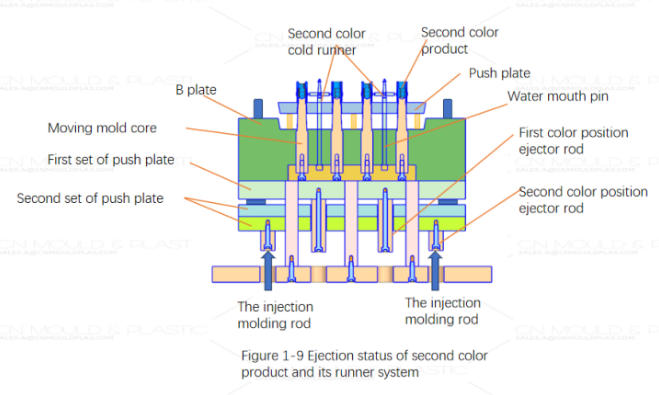

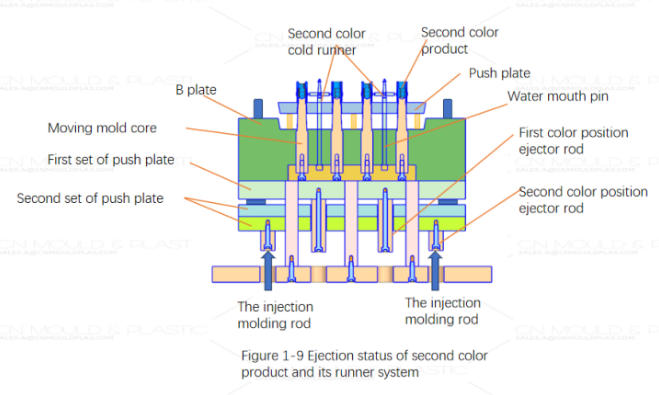

After the second material is molded, the product and the second-material cold runner are ejected at the second station. The ejector mechanism at the second station pushes the second ejector plate, which in turn drives the first ejector plate, the ejector plate, and the runner ejector pins to eject the second-material product and cold runner, as shown in Figure 1-9.

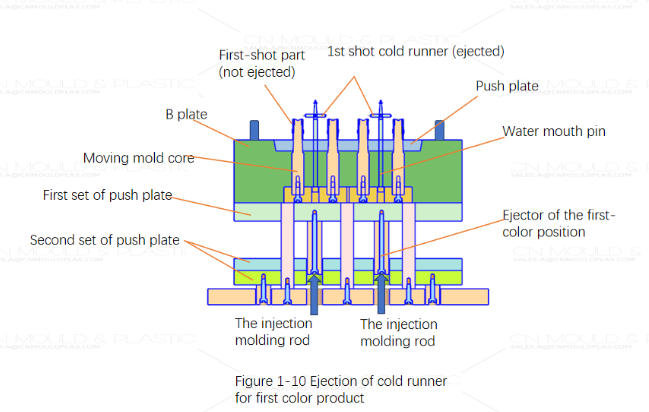

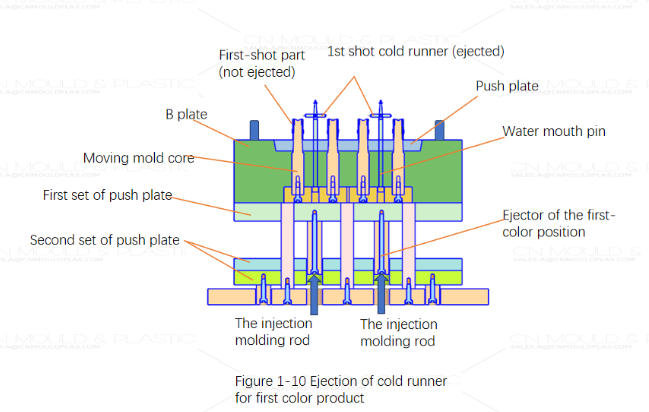

While the product and second-material runner are ejected at the second station, the ejector mechanism at the first station only pushes the first ejector plate, which then drives the runner ejector pins to eject the first-material cold runner. During this process, the second ejector plate and the ejector plate remain stationary and do not participate in ejection, leaving the first-material product retained on the moving-mold core, as shown in Figure 1-10.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk