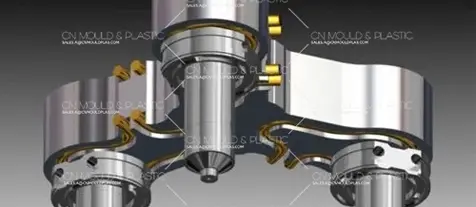

When it comes to precision injection molding, the design of valve gates plays a critical role in ensuring product quality and manufacturing efficiency. Let's explore the essential design considerations for valve gate systems.

1. Preventing Resin Leakage from the Needle Valve Stem

A primary concern is preventing resin leakage at the needle valve stem. Since the needle valve slides within the guide sleeve, an appropriate clearance must be maintained between them. However, excessive clearance leads to resin leakage, so this gap should generally not exceed 0.01mm.

Given that the manifold is heated to temperatures between 200-300°C, clearance adjustments must account for thermal expansion. The fitting clearance at room temperature needs correction to prevent seizing between the needle valve stem and guide sleeve at operating temperatures.

Both the guide sleeve and needle valve should be manufactured from hardened steel with precision grinding. Over time, wear will increase the clearance, necessitating replacement of the guide sleeve to maintain proper tolerances. Consequently, the guide sleeve should be designed for easy replacement.

When the needle valve closes, resin should not enter the sliding area. However, during opening, resin inevitably enters the sliding surfaces. With each cycle, small amounts of resin remain in the clearance, gradually being pushed inward by subsequent material. Even with leak-proof designs, axial movement of the needle valve will always allow some resin intrusion.

This trapped resin can degrade over time, affecting product performance and potentially hindering valve movement. To address this, manifolds should include resin discharge holes. However, caution is required as resin exiting these holes can damage manifold heaters.

Resin flowing along the needle valve can move to the back of the manifold. To prevent interference with valve movement, guide sleeves should feature resin collection grooves that direct material through outlets and out of the mold. These grooves should be sufficiently large to prevent clogging from solidified resin. Importantly, groove edges must not be chamfered, as this would impede resin removal from the needle valve.

The needle valve itself should incorporate two grooves. Resin entering the sliding surfaces can then be directed through these grooves, into larger channels in the guide sleeve's inner surface, and out of the mold through discharge pipes.

2. Length of the Needle Valve Stem

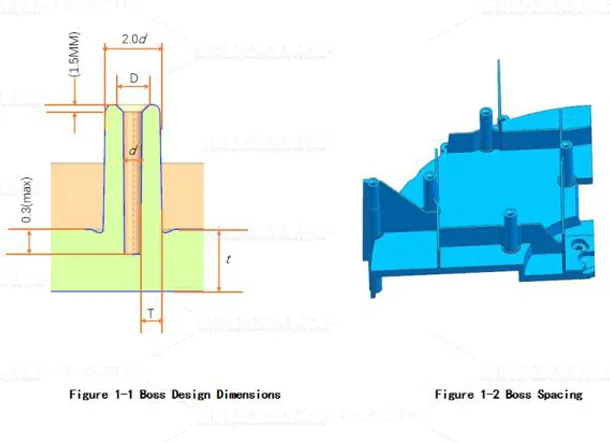

When closed, the tip of the needle valve should extend into the sprue bushing's gate. The spring force acting on the valve stem is absorbed by an adjustment pad. During injection, the valve tip should protrude slightly beyond the gate's sealing surface within a range that prevents resin leakage.

Thermal expansion of the manifold can cause misalignment between the hot runner nozzle and gate. This means the valve stem guide may not perfectly align with the gate hole. Minor centering deviations between the manifold and cavity can hinder valve movement. However, when the valve is open with the tip slightly retracted, small lateral forces on the tip will not significantly affect stem movement.

3. Closing Force of the Needle Valve

All cavities in a multi-cavity mold must operate uniformly. However, in multi-gate configurations, individual valve timing can be adjusted to achieve desired weld line characteristics.

When using hydraulic cylinders to close needle valves, timing can be controlled via time relays or pressure-adjusted switches. For spring-closed valves, adjusting spring length modifies the closing force and thus valve timing.

Increasing the closing force increases the force required to open the valve. In spring-actuated systems, this opening force comes from resin pressure. In hydraulic systems, higher closing force implies the need for higher resin pressure to open the valve. Increased resin pressure increases the likelihood of resin intrusion into the stem-sleeve clearance, potentially impairing valve movement.

In hydraulic systems, the closing force varies based on application requirements and can, in extreme cases, match the injection pressure. For spring systems, closing force is typically calculated under the premise that resin pressure between 2.94-7.85 MPa can open the valve.

In pre-compression injection molding using hydraulically actuated needle valves, there is a relationship between compression pressure, pressure drop, and resin volume increase rate – particularly for PE and PS materials. Higher resin pressure improves pre-compression efficiency, while higher resin temperatures increase volume expansion percentage. Consequently, higher valve closing pressure enhances pre-compression molding efficiency.

By carefully addressing these key considerations in valve gate design, manufacturers can achieve consistent, high-quality results in injection molding processes while maintaining efficient production cycles.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk