Wall Thickness

The wall thickness of plastic parts has a big impact on their quality. If the wall is too thin, there will be a lot of resistance when it's being formed, and it'll be hard to fill the mold cavity for large and complex plastic parts. If it's too thick, not only is there a waste of raw materials, but for thermosetting plastics, it increases the molding time and can easily lead to incomplete curing. For thermoplastic plastics, it increases the cooling time, reduces production efficiency, and also affects product quality, like causing defects such as bubbles, shrinkage cavities, and depressions. So, the wall thickness of plastic parts should be within a reasonable range.

The minimum wall thickness of plastic parts should meet the following requirements: it should have enough strength and rigidity; it can withstand the pushing force of the ejection mechanism without deformation when being demolded; and it can bear the clamping force during assembly. The minimum wall thickness of plastic parts varies depending on the type of plastic and the size of the part. Thermoplastic plastics are easy to form into thin-film parts, with a minimum wall thickness of 0.05 mm, but generally, it's better not to be less than 0.6 mm, and usually 2-4 mm is a good range.

Table 1-1: Reference Values for Minimum and Recommended Wall Thicknesses of Thermoplastic Parts. Unit: mm

Type of Plastic | Minimum Wall Thickness for Parts with Width 50mm | Wall Thickness for Large Parts | Wall Thickness for Large Parts |

Polyamide (PA) | 0.45 | 1.0~1.5 | 2.4~5.2 |

Polyethylene (PE) | 0.75 | 2.5~2.60 | 5.2~5.4 |

Modified Polyethylene | 0.75 | 2.5~2.60 | 3.2~5.4 |

Isotactic Polypropylene (PPMA) | 0.80 | 2.5~2.80 | 4~6.5 |

Polyoxymethylene (POM) | 0.85 | 2.50~2.60 | 3.2~5.4 |

Soft Polyvinyl Chloride (LPVC) | 0.85 | 2.55~2.55 | 2.4~3.2 |

Polypropylene (PP) | 0.85 | 2.35~2.75 | 2.4~3.2 |

Chlorinated Polyether (CPT) | 0.85 | 2.35~2.75 | 2.5~3.4 |

Polycarbonate (PC) | 0.95 | 2.60~2.80 | 3~4.5 |

Hard Polyvinyl Chloride (HPVC) | 1.15 | 2.80~2.80 | 5.2~5.8 |

Polystyrene (PS) | 1.20 | 2.75~3.10 | 3.5~6.4 |

Polyethylene (PE) | 0.60 | 2.75~2.80 | 4.2~4.2 |

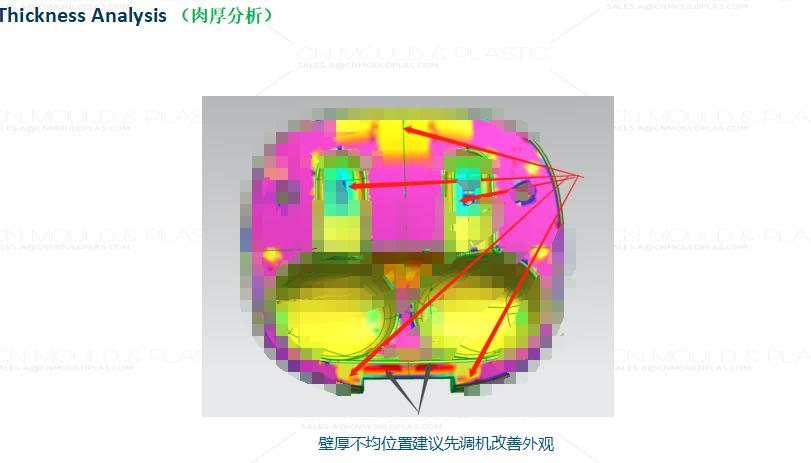

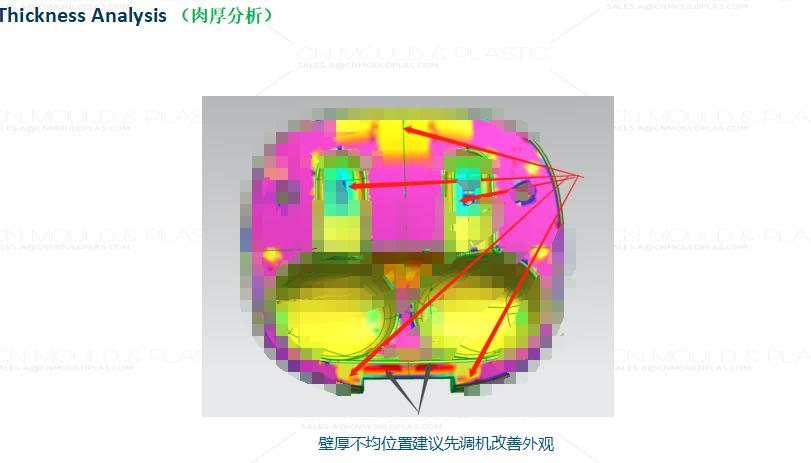

The wall thickness of the same plastic part should be as uniform as possible. Otherwise, internal stress will be generated due to different cooling or curing speeds, causing the part to warp, have shrinkage cavities, cracks, or even break. Of course, it's impossible to have completely uniform wall thickness everywhere on the part. So, to make the wall thickness as uniform as possible, we often hollow out the thicker parts when possible. If the structure requires different wall thicknesses, the ratio of the thicknesses shouldn't exceed 3:1, and appropriate transition radii should be used to make a smooth transition between different thickness sections.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk