The gating system is the circulatory system of an injection mold. Its design directly impacts part quality, production efficiency, and tool longevity. Key design elements include the sprue, runner layout, cross-sectional shape and dimensions, as well as gate location, type, and size.

Here are 12 essential principles to guide the design of an effective and reliable gating system:

Keep runner pathways as straight as possible with minimal bends. The internal surface should be smooth, with a recommended roughness between Ra 1.6 to Ra 0.8 μm, to facilitate smooth plastic flow and reduce pressure loss.

The design must align with the mold layout. For multi-cavity molds, the runner system should be balanced and symmetrical around the mold centerline to ensure uniform filling.

For parts with a large projected area, avoid placing gates on only one side of the mold. An unbalanced gate location can create uneven pressure during injection, leading to mold deflection and potential part defects.

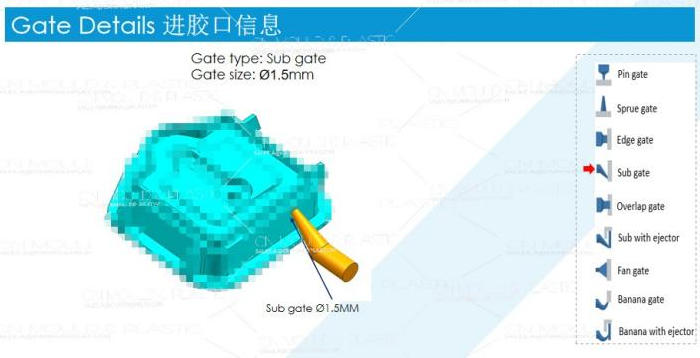

Design for easy gate detachment. The gate should be easy to trim without leaving visible marks on the finished part. For pinpoint gates, pay special attention to the design of the gate break-off point to ensure clean runner separation.

Avoid placing parts with significantly different sizes and weights in the same multi-cavity mold. Disparate parts require different fill times and pressures, making balanced filling nearly impossible and compromising quality.

When designing the sprue, prevent high-velocity molten plastic from directly impinging on small-diameter core pins or inserts. Direct impact can cause them to bend, shift, or even break.

Select the shortest possible flow path that allows for proper filling and venting. Shorter flows reduce fill time, require lower injection pressure, and minimize material shear and cooling.

Position the gating system on the parting plane whenever possible. This simplifies machining and helps achieve rapid, uniform, and balanced filling of the cavity.

For mass production, design the system for automatic degating—where runners and gates separate from the part automatically upon ejection. This is crucial for reducing cycle time and enabling unattended automated operation.

The sprue area is prone to shrinkage. If high dimensional accuracy is required at the sprue contact point on the part, include a machining or correction allowance in the sprue design.

Position the gate so that molten plastic flows directly into the wider and thicker sections of the cavity. This promotes smoother filling and helps prevent issues like short shots or excessive weld lines.

Weld lines are often inevitable, but their location can be controlled. Design the gate location to avoid creating weld lines in critical cosmetic or high-stress areas. If they must occur, steer them to non-essential parts of the component.