Flash—the thin, unwanted excess of material along mold parting lines or ejector pins—is one of the most common defects in injection molding. Not only does it affect part appearance and dimensions, but it also increases post-processing time and cost. Understanding the root causes of flash is the first step toward prevention.

Here’s a breakdown of the main causes and systematic solutions based on practical experience and material science.

1. Insufficient Clamping Force

When injection pressure exceeds the clamping force holding the mold shut, the mold can slightly open, allowing material to escape as flash.

Solution:

Check if injection pressure is set too high.

Verify that the product’s projected area × molding pressure does not exceed the machine’s clamping capacity.

General rule: Average molding pressure ≈ 40 MPa.

For box-shaped parts (PE, PP, PS, ABS): ≈ 30 MPa.

For deep-shaped parts: ≈ 36 MPa.

For small parts (<10 cm³): ≈ 60 MPa.

If clamping force is too low:

Reduce injection pressure or decrease gate cross-sectional area.

Shorten holding/packing time and injection stroke.

Reduce the number of cavities or switch to a machine with higher clamping tonnage.

2. Melt Temperature Too High

High temperatures reduce melt viscosity, making the material flow more easily into tiny gaps between mold components.

Solution:

Lower barrel, nozzle, and mold temperatures.

Shorten the injection cycle to reduce heat exposure.

For low-viscosity materials like Polyamide (Nylon):

It’s often hard to eliminate flash solely by adjusting process parameters.

Combine lower melt temps with precision mold polishing and maintenance to minimize mold gaps.

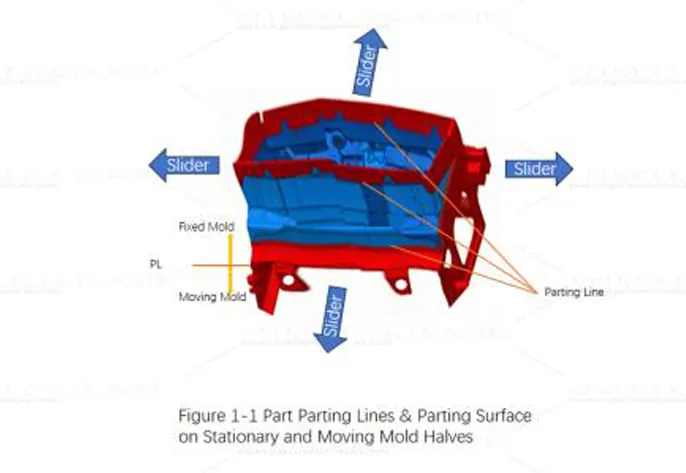

3. Mold Design and Wear Issues

In many cases, flash is primarily a mold-related issue.

Checklist for mold inspection:

Are parting surfaces properly aligned and tightly sealed?

Are there wear gaps in sliding components (cores, cavities, slides)?

Is there contamination or damage on parting surfaces?

Are mold plates parallel, or do they show bending or deformation?

Is the mold opening distance correctly set based on mold height?

Are guide pins, tie rods, or vents worn or damaged?

Are venting channels too large or deep?

Action:

Repair or re-machine mold components to restore precision. Regular mold maintenance is essential.

4. Improper Process Control

Even with a good mold and machine, incorrect settings can induce flash.

Common process-related causes:

Injection speed too high

Injection time too long

Uneven pressure distribution in the cavity

Overpacking or excessive feed

Too much lubricant in the material

Adjustment strategy:

Optimize speed-pressure profiles, reduce dosing amount, and ensure consistent filling.

Important Tip: Always start troubleshooting flash by inspecting the mold. Adjusting process parameters or material formulation as a first response can lead to other defects like short shots or sink marks.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk