Product Description

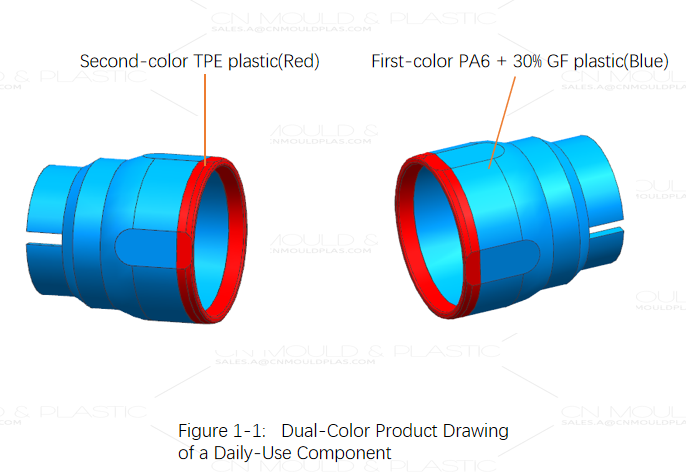

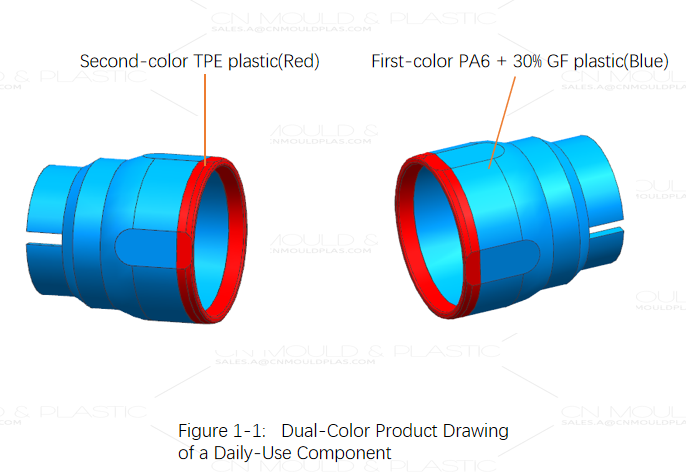

The diagram in Figure 1-1 shows a two-color daily-use part. Its average wall thickness is 3.5mm, and the outer dimensions are ф76mm x 108mm. The green part is made of the first-color material: PA6 + 30% GF, weighing 83g. The orange part is the second-color material: TPE (soft rubber), weighing 5.3g. The product has a simple structure, and the mold is required to produce 1+1 cavities per cycle.

Key Design Points

1. Parting Surface and Mold Opening Direction

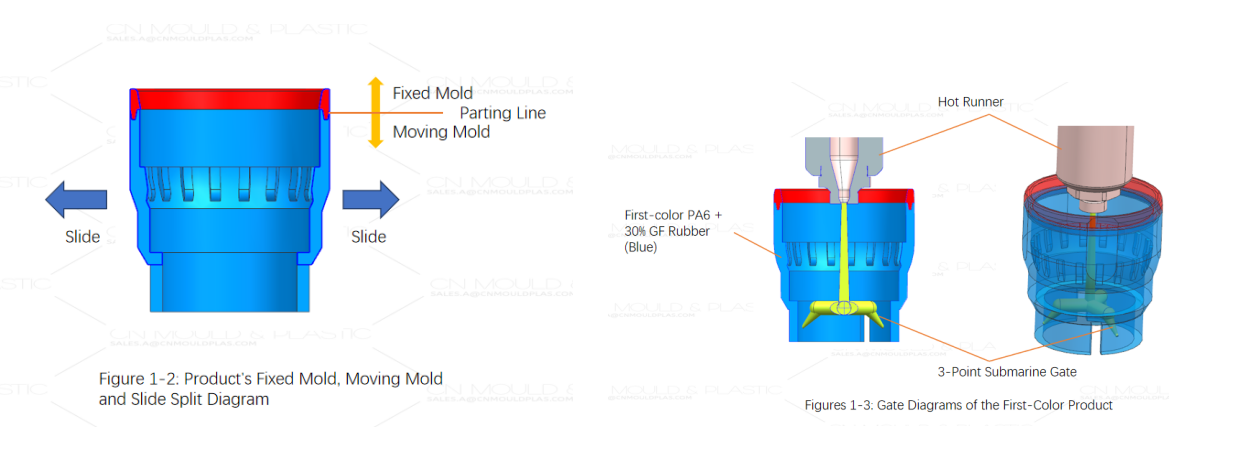

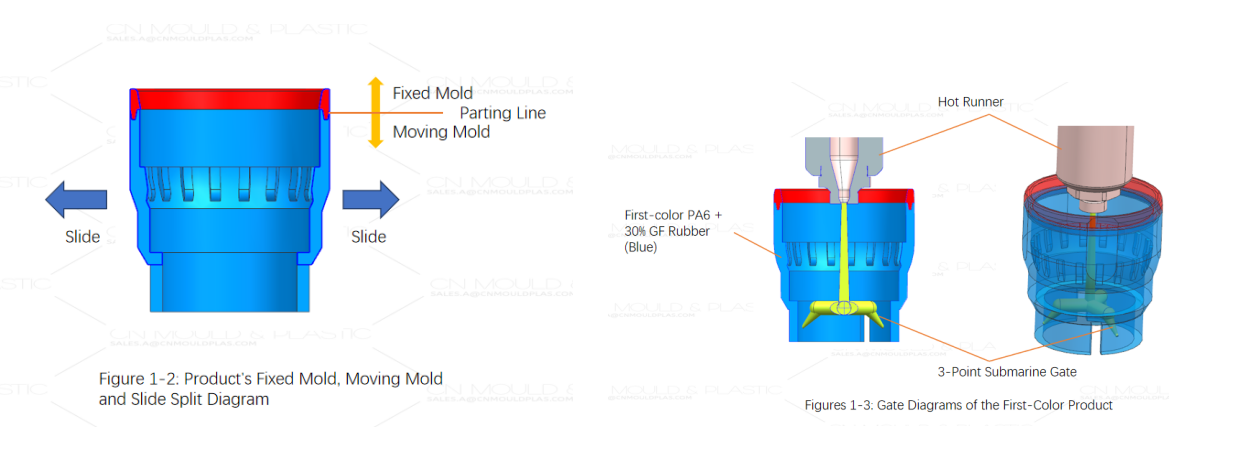

This product has a simple structure and a straightforward parting surface, which fully meets the basic principles of simple two-color mold design: the fixed mold has different product shapes, while the moving mold has identical product shapes. The parting surface between the moving and fixed molds for this two-color product is a flat surface. Since the first-color part has a hole feature on its side, we can use left-right half slides for molding. Figure -2 shows the parting diagram of the product’s fixed mold, moving mold, and slides.

2. Gate Setup

The key to designing this two-color mold lies in the structure of the gating method for the second-color soft rubber. The first-color material is PA6 + 30% GF, which has obvious flow anisotropy and can easily cause product deformation. Additionally, the middle part of the product is circular with strict dimensional requirements. So, for the first-color PA6 + 30% GF, we use a hot runner connected to 3 submarine gates, as shown in Figure 1-3.

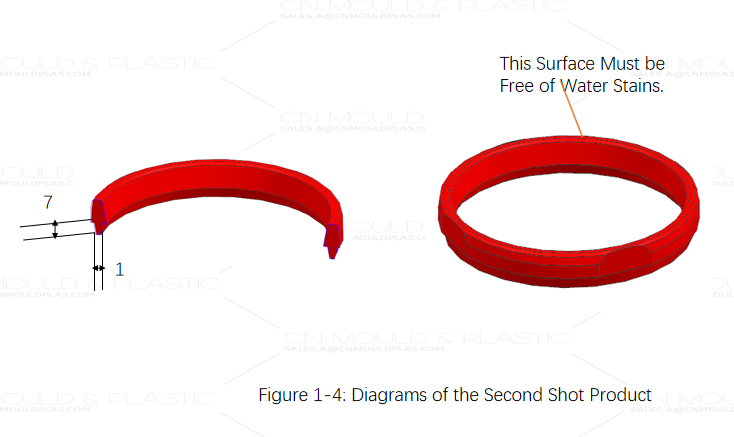

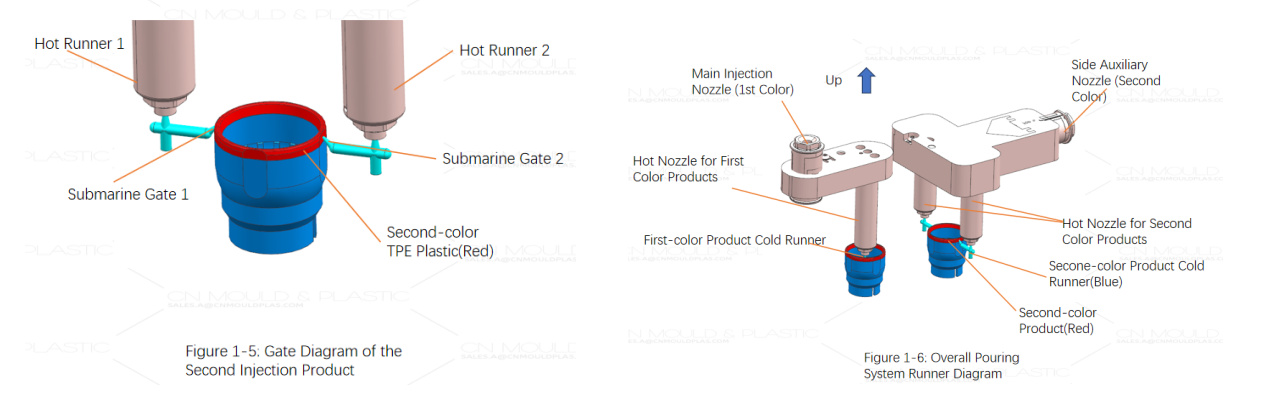

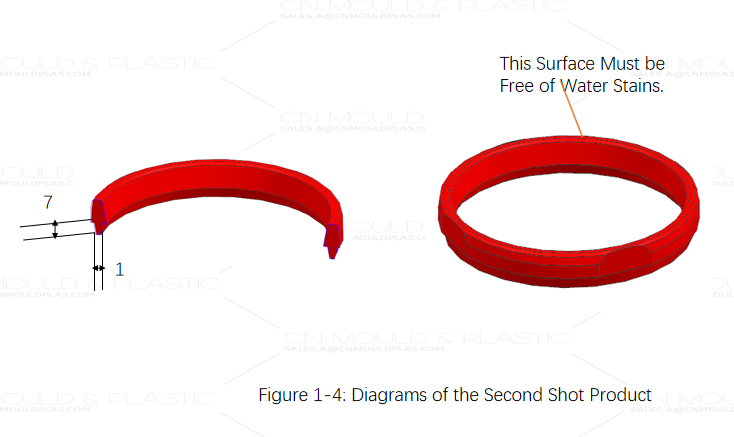

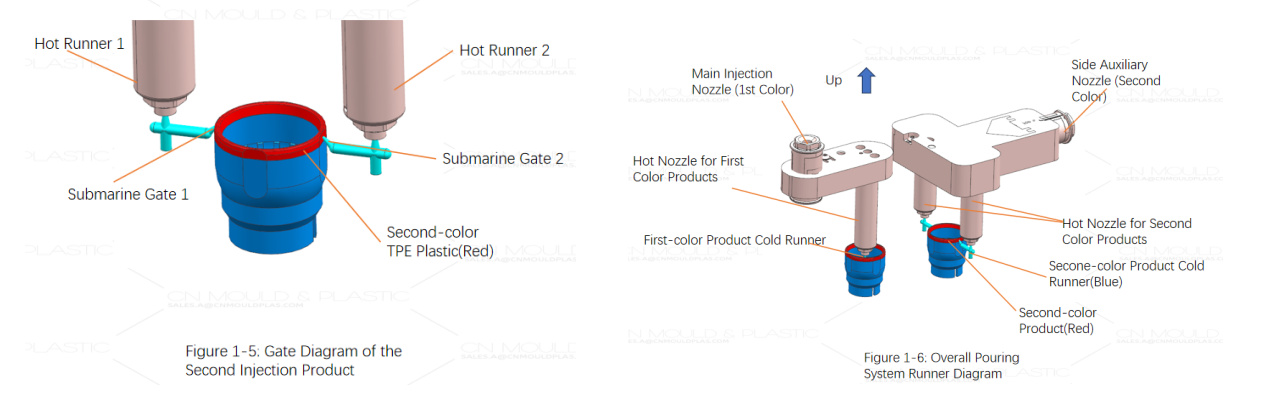

For the second-color TPE material: the product has a full circle of thin rubber with a height of 7mm and a thickness of 1mm, and there must be no gate marks on the end face. After comprehensive consideration, we use a hot runner connected to 2 side submarine gates, as shown in Figures 1-4 and 1-5.

Figure 1-6 shows the overall runner system diagram of this mold set.

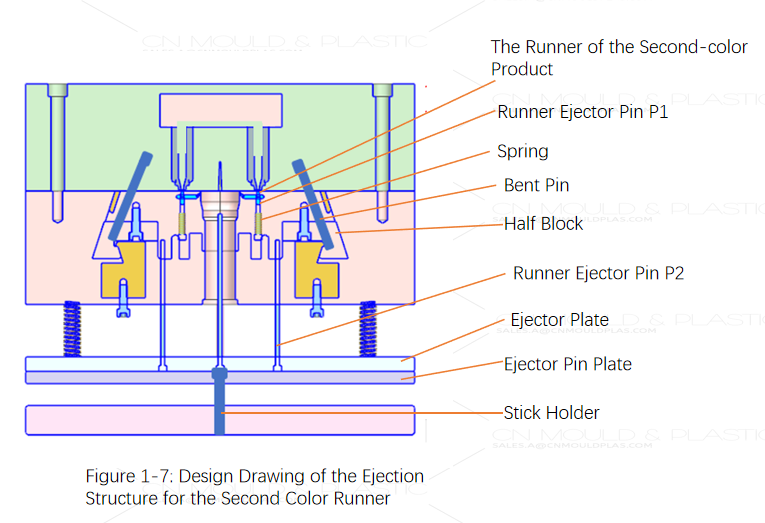

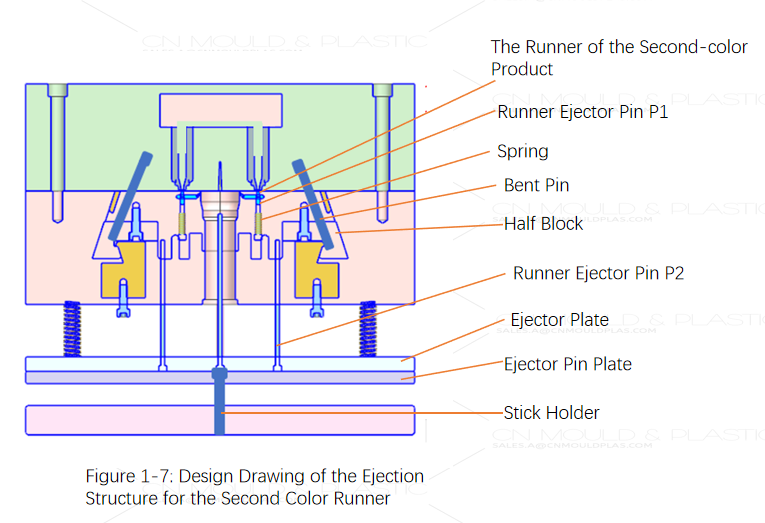

Since the product has a snap feature on its outer shape, a left-right half slide structure is necessary. The key challenge in designing this two-color mold is figuring out how to design the runner for the second-color part on the half slides and how to eject that runner. As shown in Figure 1-7, we’ve added a spring and ejector pin structure inside the half slides—this solves the problem of ejecting the cold runner from the half slides.

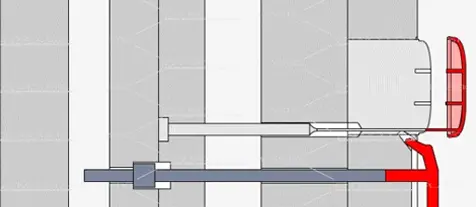

After the injection molding machine finishes injecting the second-color TPE soft rubber, when the mold opens, the angle pins fixed on the fixed mold (see Figure 1-7) drive the slides to pull the core, completing the core-pulling action of the half slides. Once core-pulling is done, the half slides move by a distance of S1, and then the ejector rods of the injection molding machine’s moving mold start the ejection process. The ejector pin P1 on the ejector plate pushes the runner ejector pin P2 inside the half slides, realizing the ejection of the second-color soft rubber runner, as shown in Figure 1-8.

3. Product Ejection

The ejection structure of this two-color mold is relatively simple. After completing the two-color injection molding, when the mold opens, the left-right half slides move under the action of the angle pins (see Figure 1-7) to finish core-pulling. Then, the ejector rods, push plates, and ejector pins of the injection molding machine’s moving mold eject the product and runner out of the cavity respectively. Finally, a robot takes away the product and runner, as shown in Figure 1-9. Note that the first-color product is not ejected after injection; both the product and the cold runner are ejected at the second-color station.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk