(1) Barrel Temperature

Feed Zone 50–70°C (70°C recommended)

Zone 1 230–250°C (240°C recommended)

Zone 2 240–260°C (250°C recommended)

Zone 3 250–260°C (260°C recommended)

Zone 4 250–260°C (260°C recommended)

Zone 5 250–260°C (260°C recommended)

Nozzle 250–260°C (260°C recommended)

The values in parentheses are recommended as basic settings, with a stroke utilization of 35% and 65%, and a flow-length-to-wall-thickness ratio of 50:1 to 100:1.

(2) Melt Temperature 250–260°C; the processing window is narrow. The material tends to solidify below 240°C and may degrade thermally above 270°C.

(3) Barrel Constant Temperature 210°C.

(4) Mold Temperature 60–80°C.

(5) Injection Pressure 100–140 MPa (1000–1400 bar).

(6) Holding Pressure 50–60% of the injection pressure.

(7) Back Pressure 5–10 MPa (50–100 bar); avoid generating frictional heat.

(8) Injection Speed High speed is required due to the high solidification and crystallization rates. Avoid cooling and solidification of the melt during injection. Good venting in the mold is essential; otherwise, trapped air can cause burning at the end of flow paths.

(9) Screw Speed Maximum screw speed corresponds to a linear velocity of 0.5 m/s.

(10) Metering Stroke (0.5–3.5)D. The melt is sensitive to overheating and prolonged residence time in the barrel; residence time should not exceed 5 minutes.

(11) Cushion 2–5 mm, depending on the metering stroke and screw diameter.

(12) Pre-drying Dry at 120°C for 4 hours.

(13) Regrind Ratio For flame-retardant grades, up to 10% regrind may be used provided it is pre-dried and shows no thermal degradation. For non-flame-retardant grades, up to 20% regrind can be added.

(14) Shrinkage Shrinkage depends largely on mold temperature; higher mold temperature leads to greater shrinkage. Typical shrinkage is 1.4–2.0%. Adding 30% glass fiber can reduce shrinkage to 0.4–0.6%.

(15) Gating System For glass-fiber-reinforced grades, avoid center-direct sprue and pin-point gates. The gate location should ensure uniform filling of the cavity. Hot-runner systems must be equipped with closed-loop temperature control.

(16) Machine Shutdown Period Turn off the heating system and run the machine like an extruder until no more plastic is expelled. When restarting after a production interruption, purge until the melt is free of bubbles.

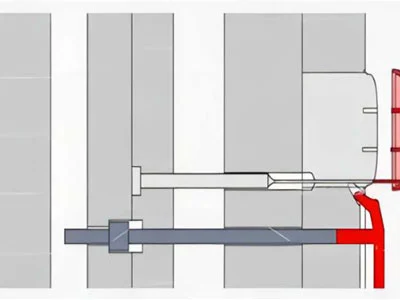

(17) Barrel Equipment Standard screw, non-return valve, and open nozzle.

English

English  français

français  Deutsch

Deutsch  Español

Español  italiano

italiano  русский

русский  português

português  العربية

العربية  dansk

dansk  Suomi

Suomi  Svenska

Svenska  norsk

norsk